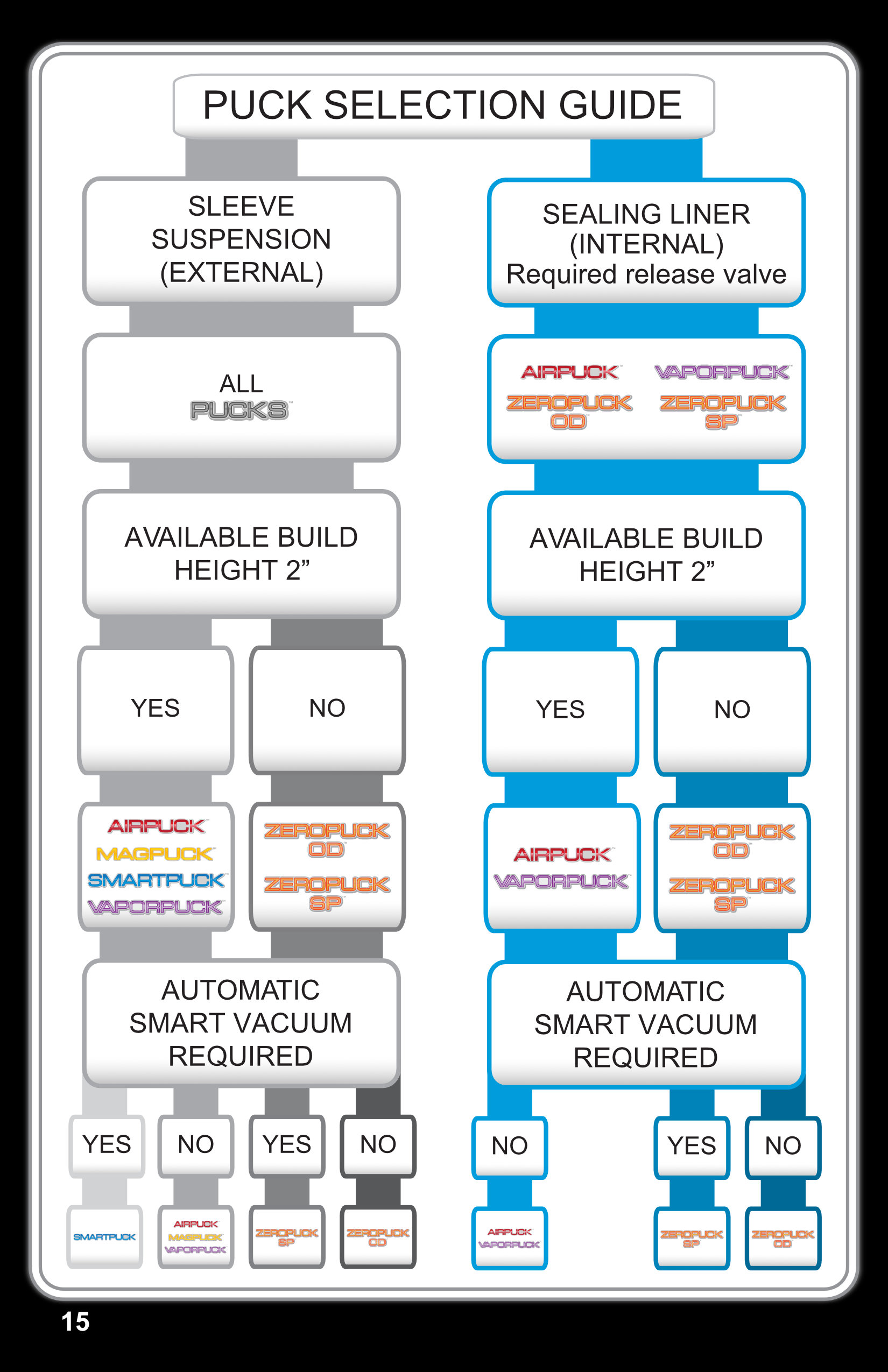

Socket Technology Catalog

At Adaptec Prosthetics, I worked as a contractor redesigning several educational booklets.

This is the catalog that gives clients an overview of all of Adaptec Prosthetics's products. VaporPuck is a product that Adaptec Prosthetics used to sell.

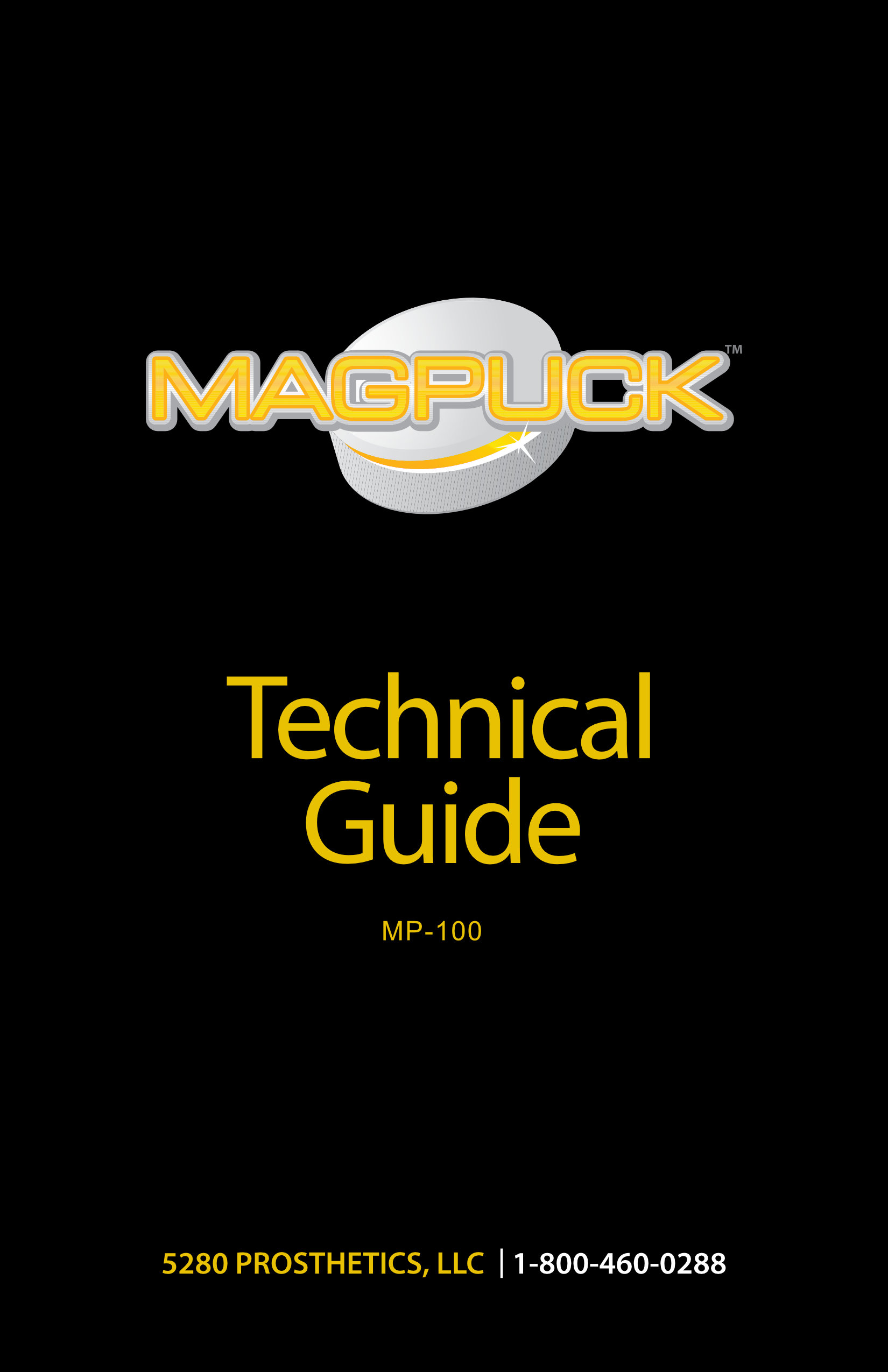

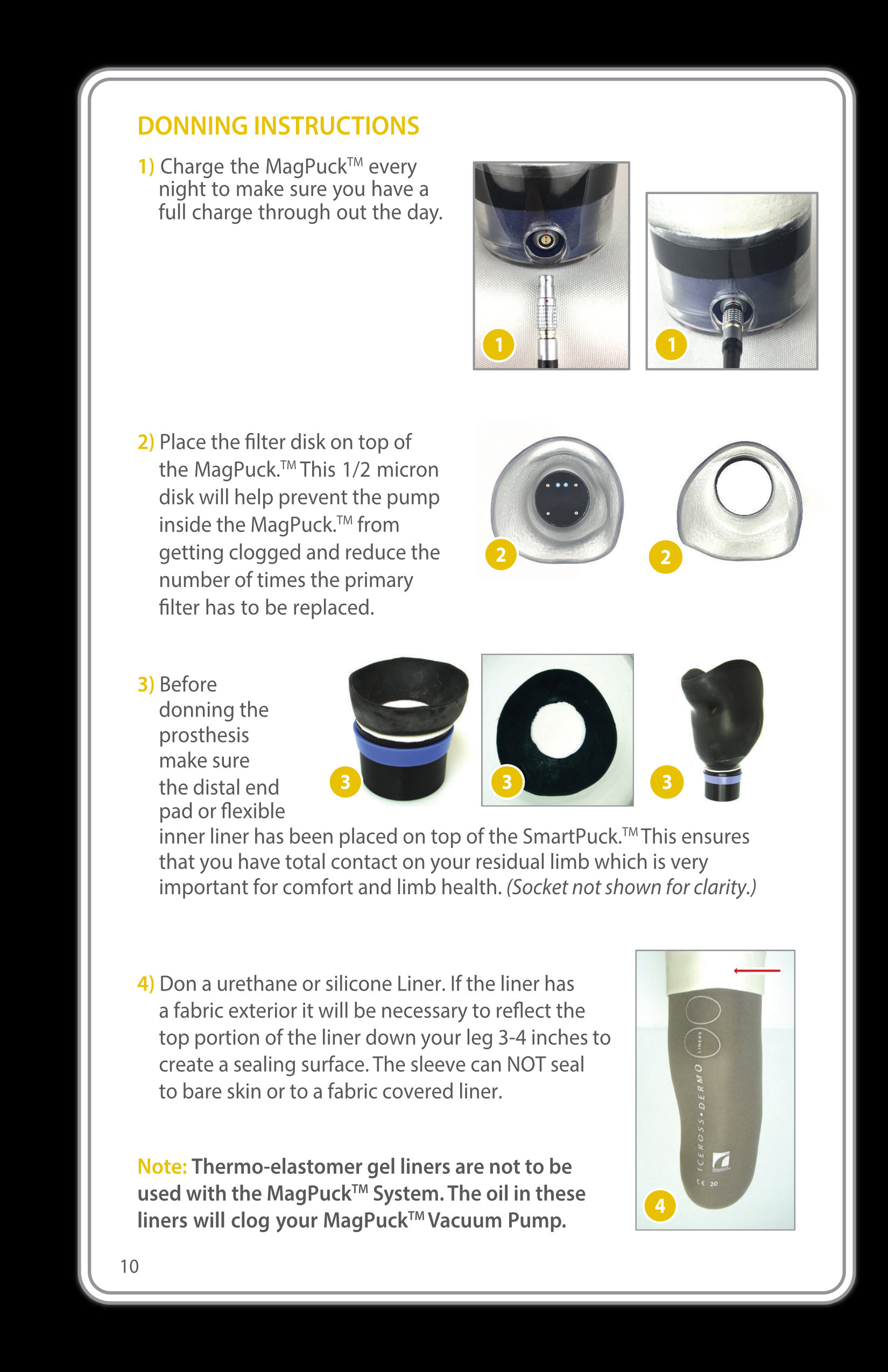

MagPuck Technical Guide

At Adaptec Prosthetics, I worked as a contractor redesigning several educational booklets.

"The MagPuck is a modular socket computer system that utilizes an electronic vacuum pump to create negative pressure inside the prosthetic socket. The MagPuck improves the linkage between the residual limb and the prosthesis. The MagPuck is equipped with an easy to use magnetic switch, allowing the user to quickly and easily set and adjust vacuum levels of their prosthesis."

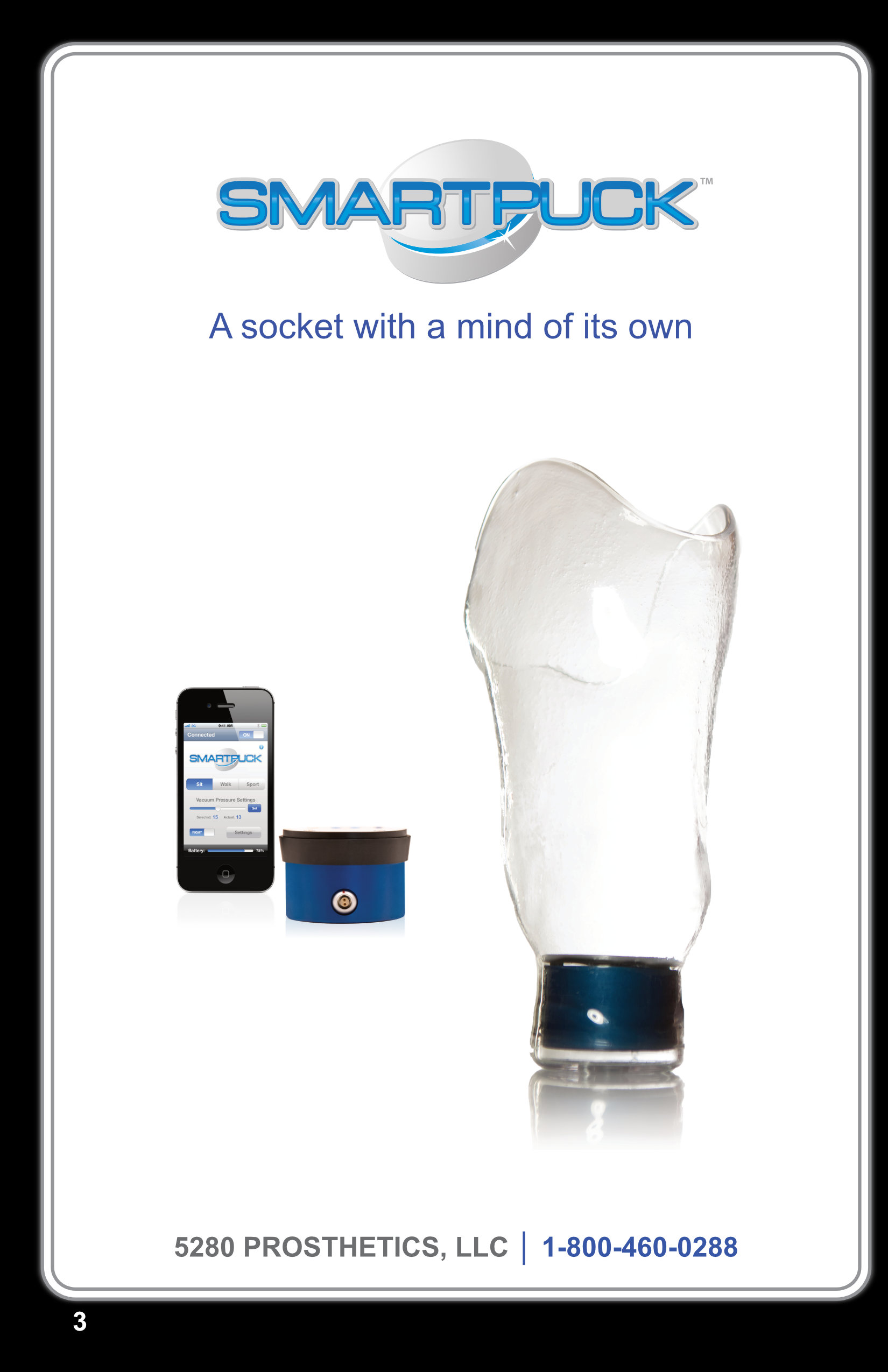

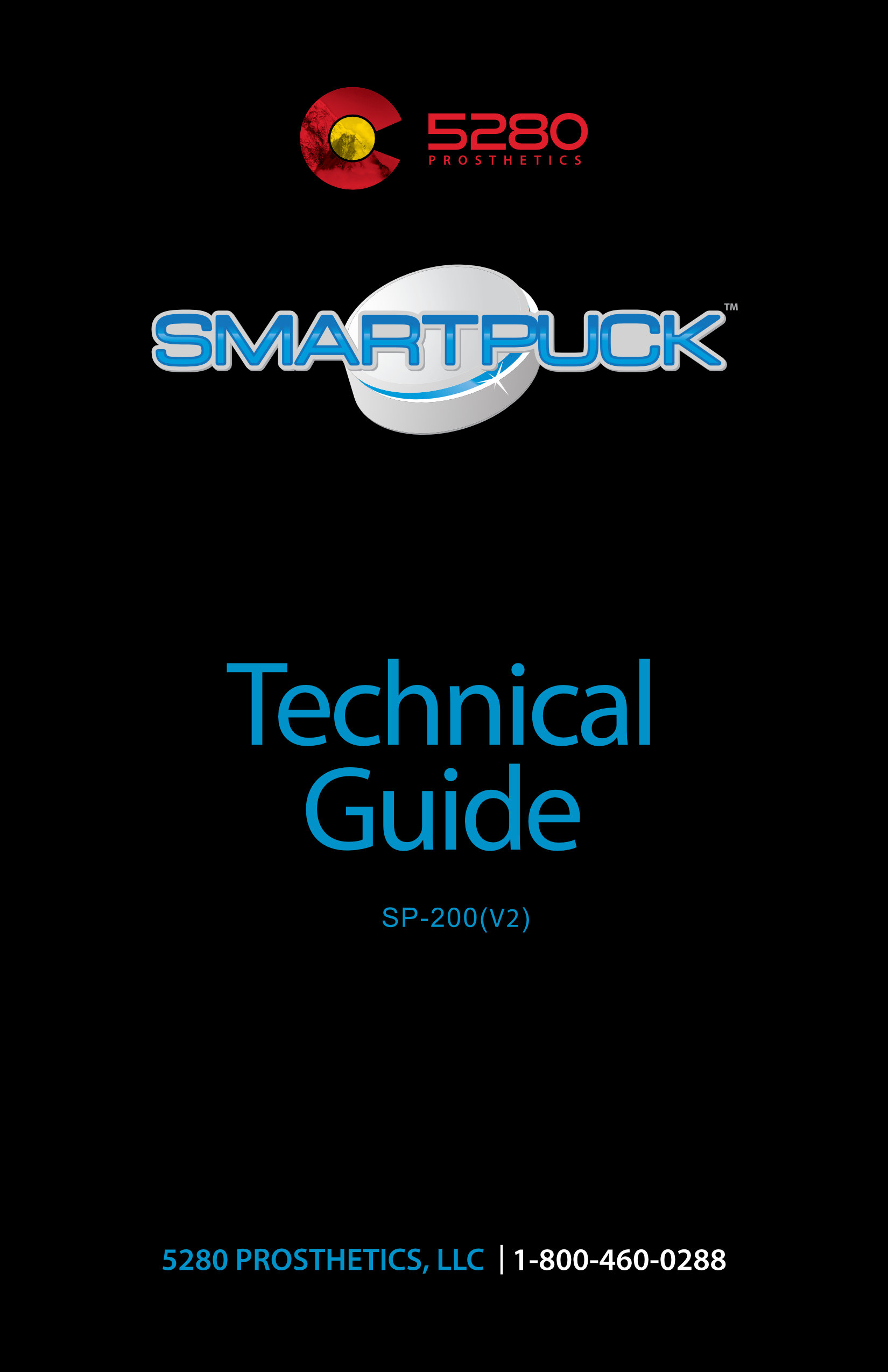

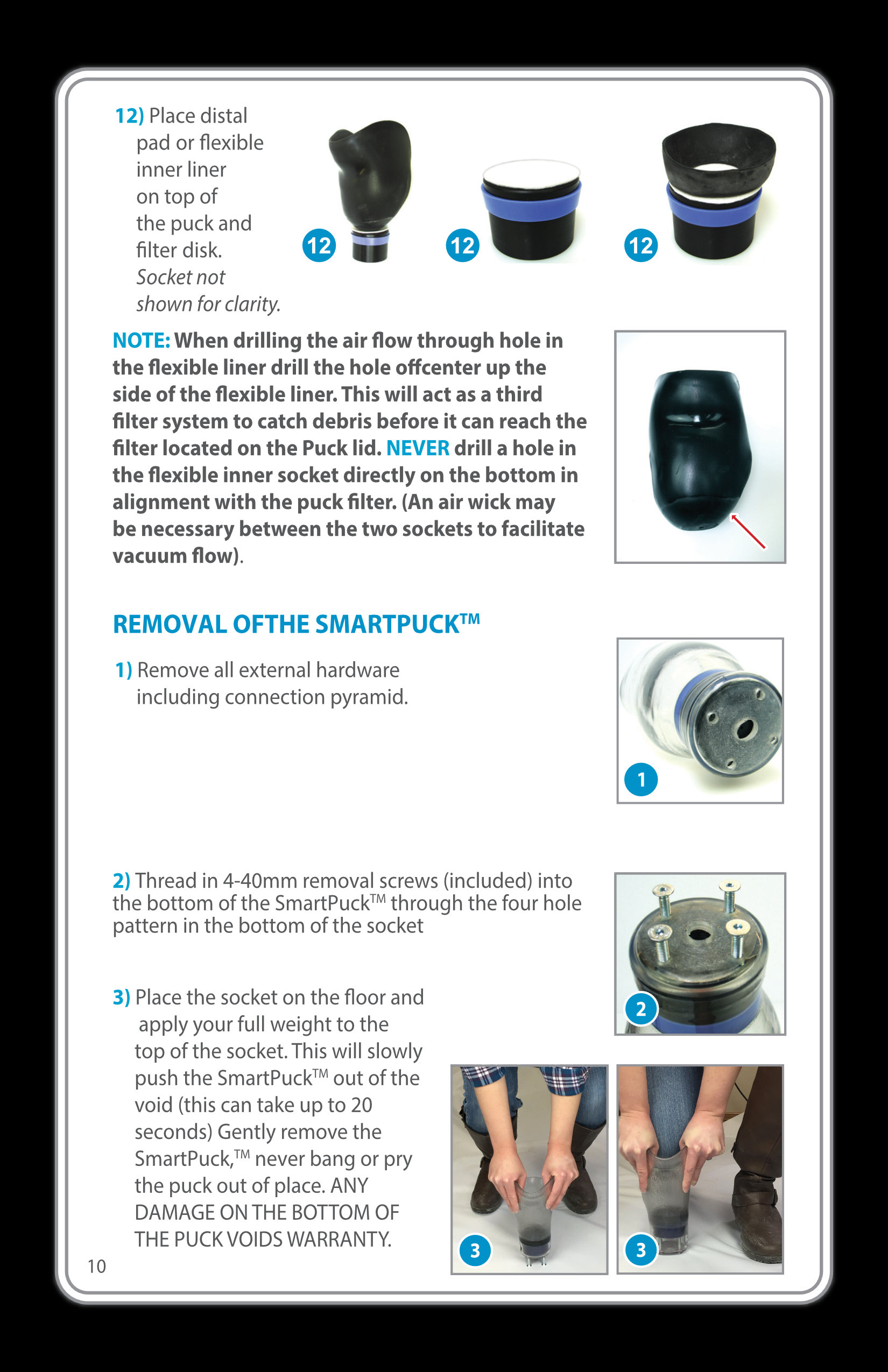

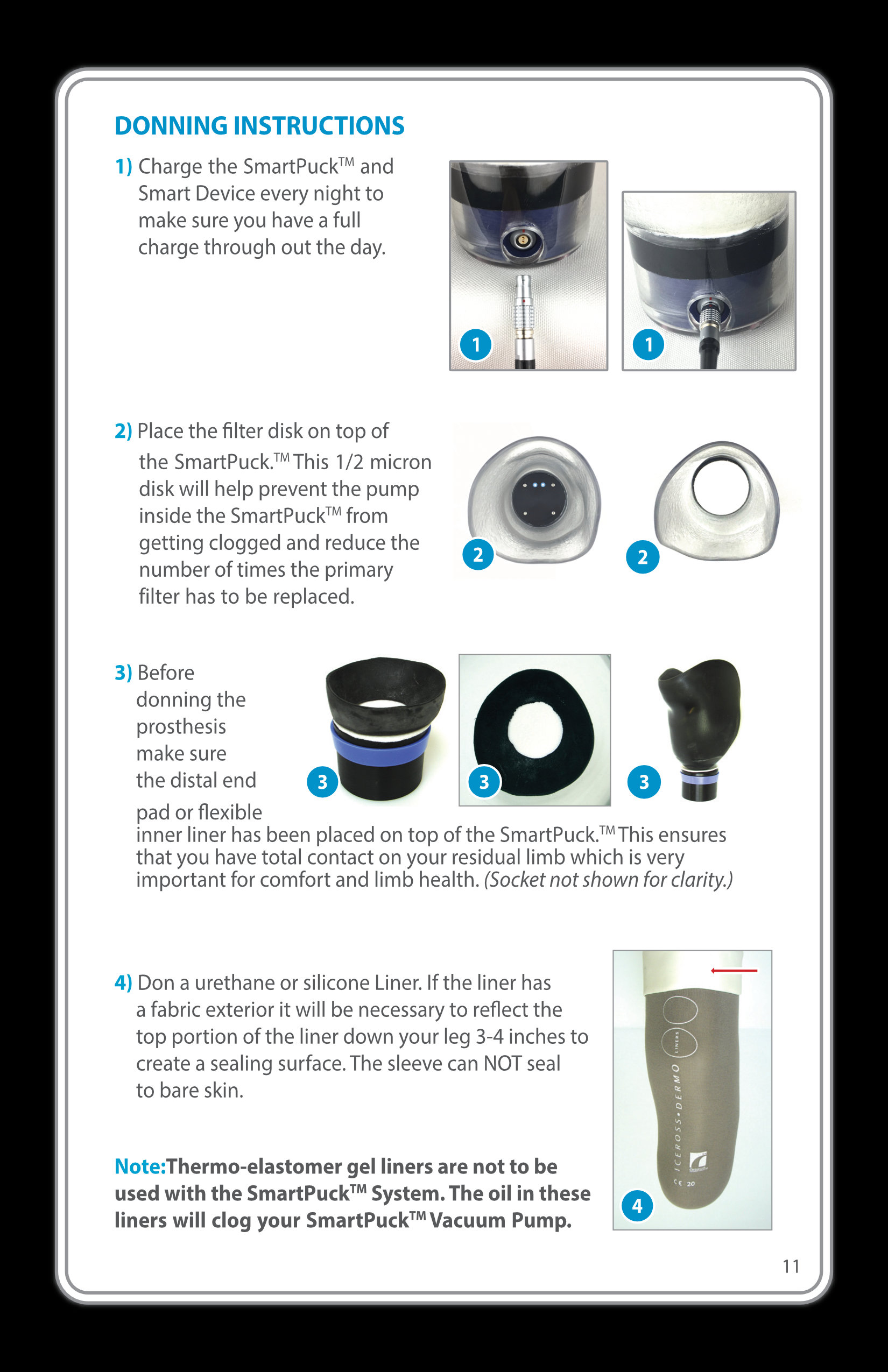

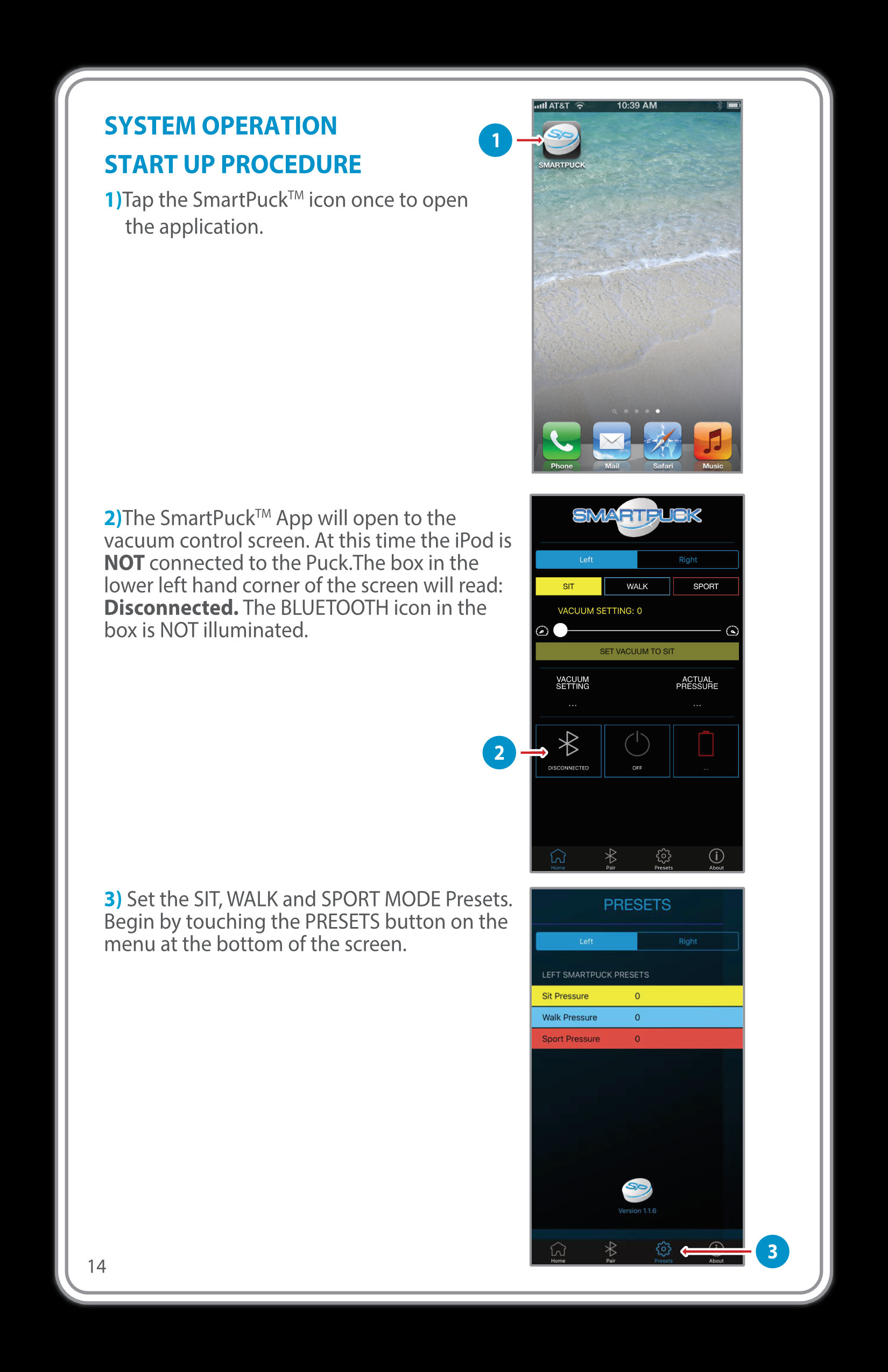

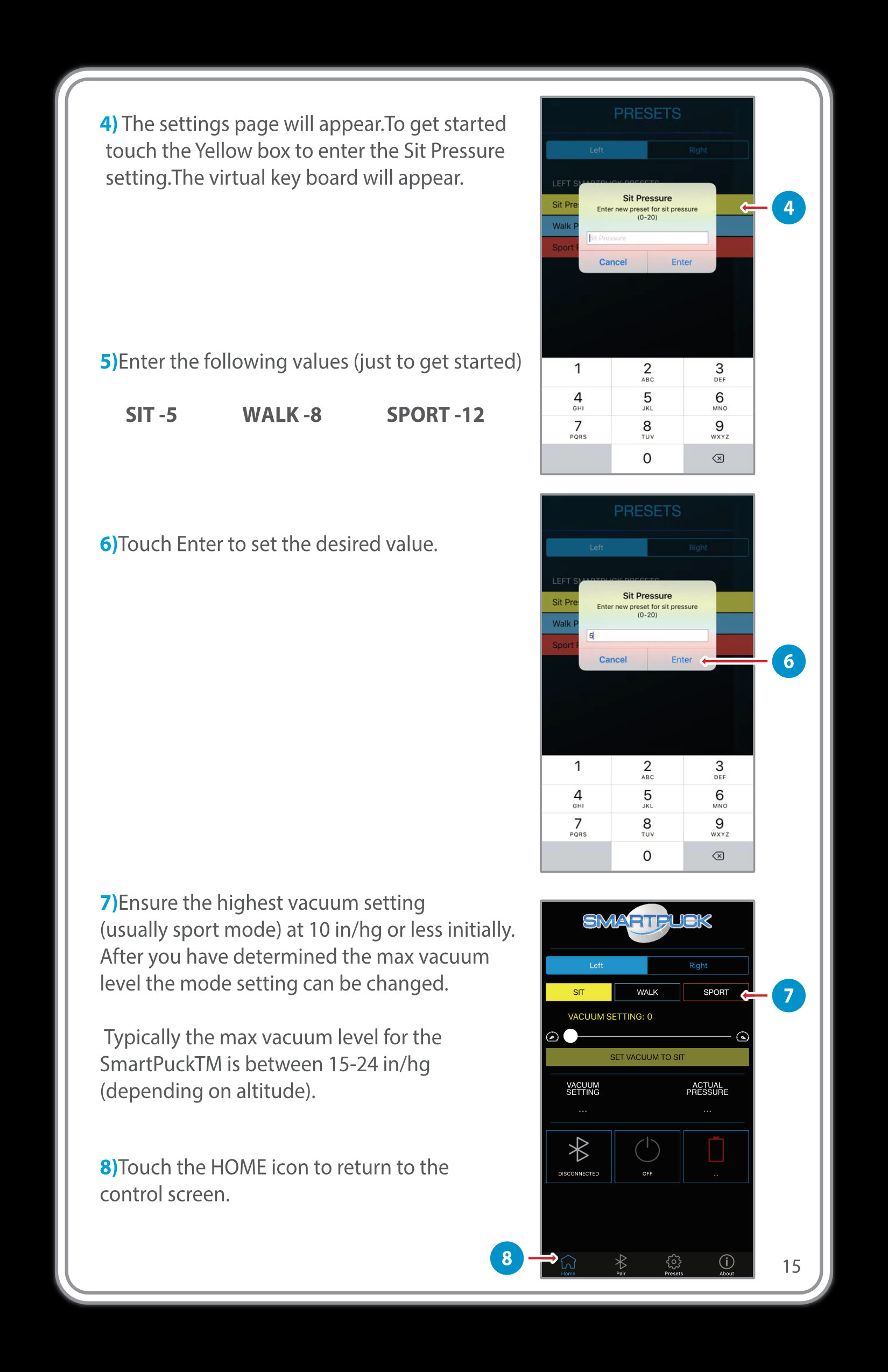

SmartPuck Technical Guide

At Adaptec Prosthetics, I worked as a contractor redesigning several educational booklets.

"The SmartPuck is a modular socket computer system that utilizes an electronic vacuum pump to create negative pressure inside the prosthetic socket. The SmartPuck improves the linkage between the residual limb and the prosthesis. The SmartPuck is equipped with an easy to use iDevice and application interface, allowing the user to quickly and easily set and adjust vacuum pressure settings of their prosthesis."

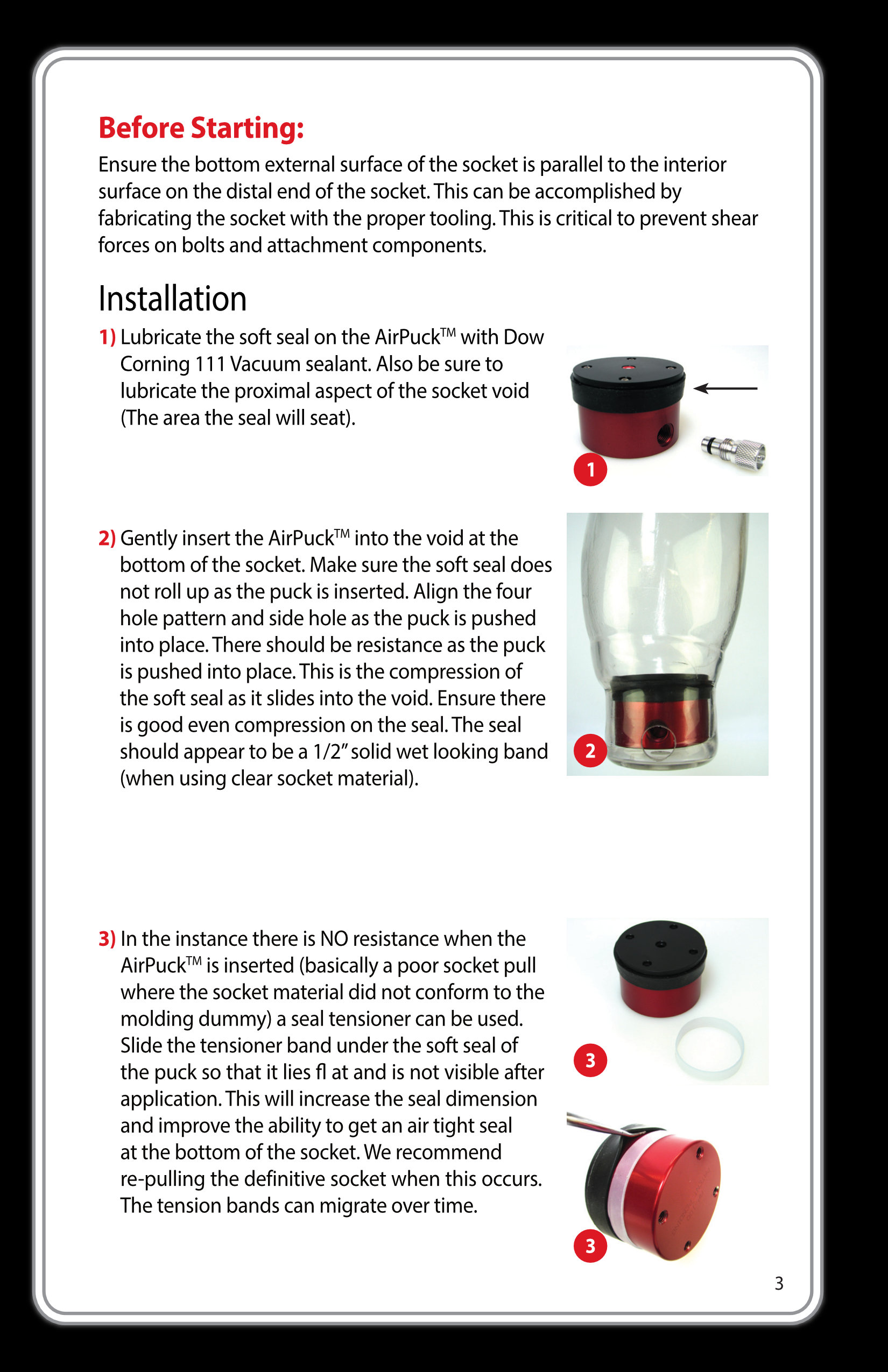

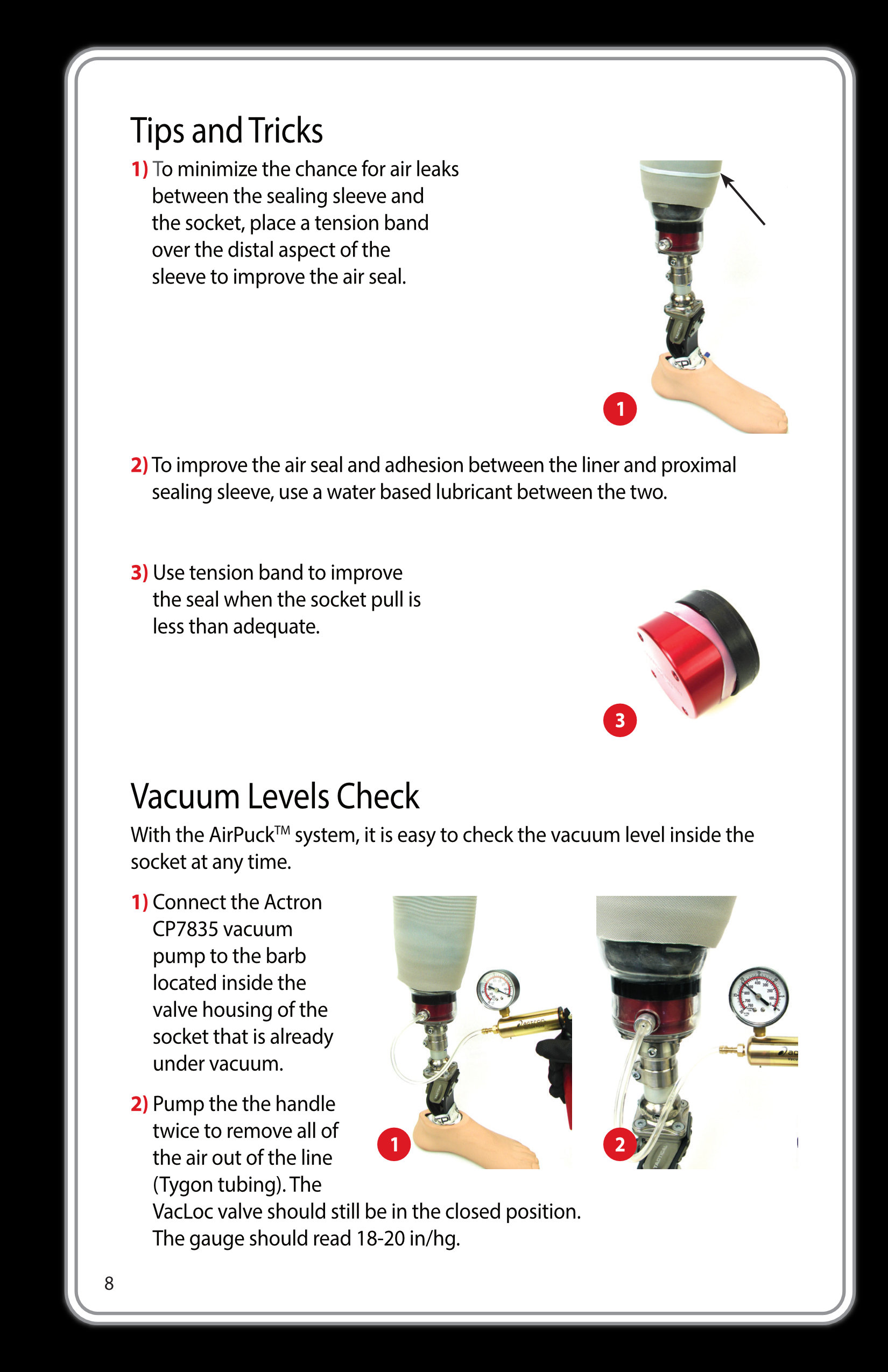

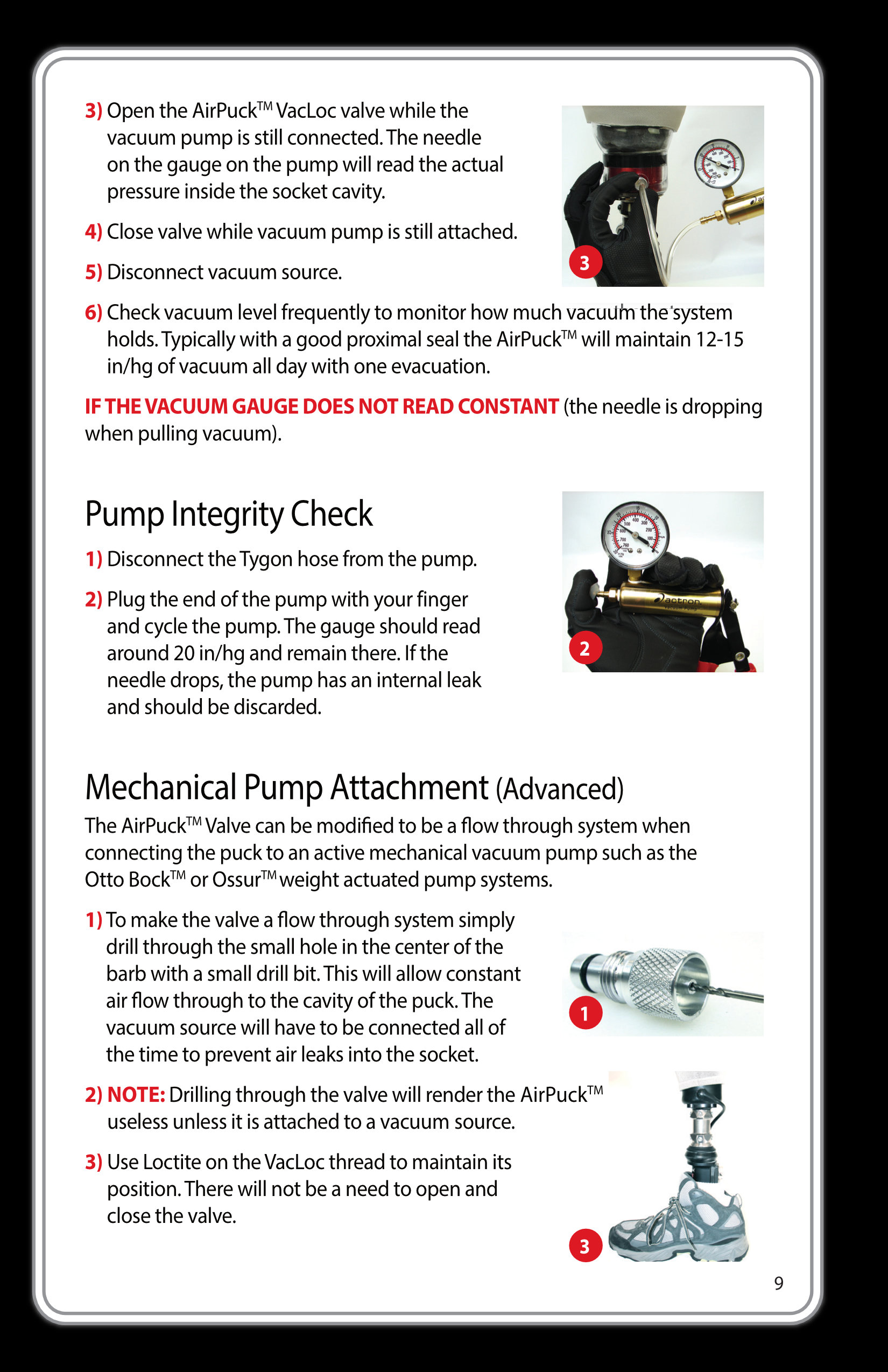

AirPuck Technical Guide

At Adaptec Prosthetics, I worked as a contractor redesigning several educational booklets.

The AirPuck is the base product Adaptec Prosthetics offers. It uses a simple air system.

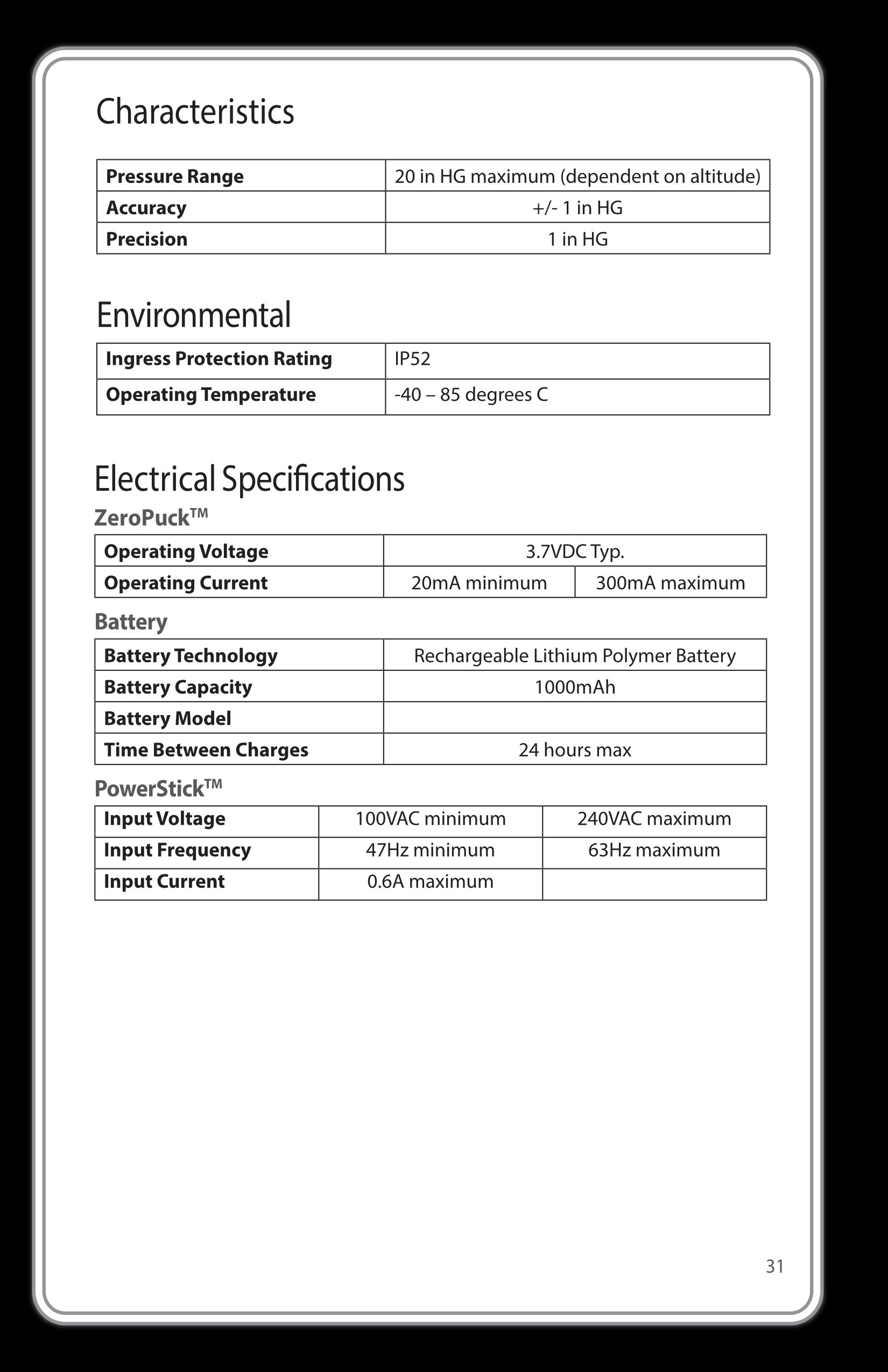

ZeroPuck Technical Guide

At Adaptec Prosthetics, I worked as a contractor redesigning several educational booklets.

"The ZeroPuck is a modular socket computer system that utilizes an electronic vacuum pump to create negative pressure inside the prosthetic socket. The ZeroPuck improves the linkage between the residual limb and the prosthesis. The ZeroPuck is equipped with an easy to use iDevice and application interface, allowing the user to quickly and easily set and adjust vacuum pressure settings of their prosthesis."

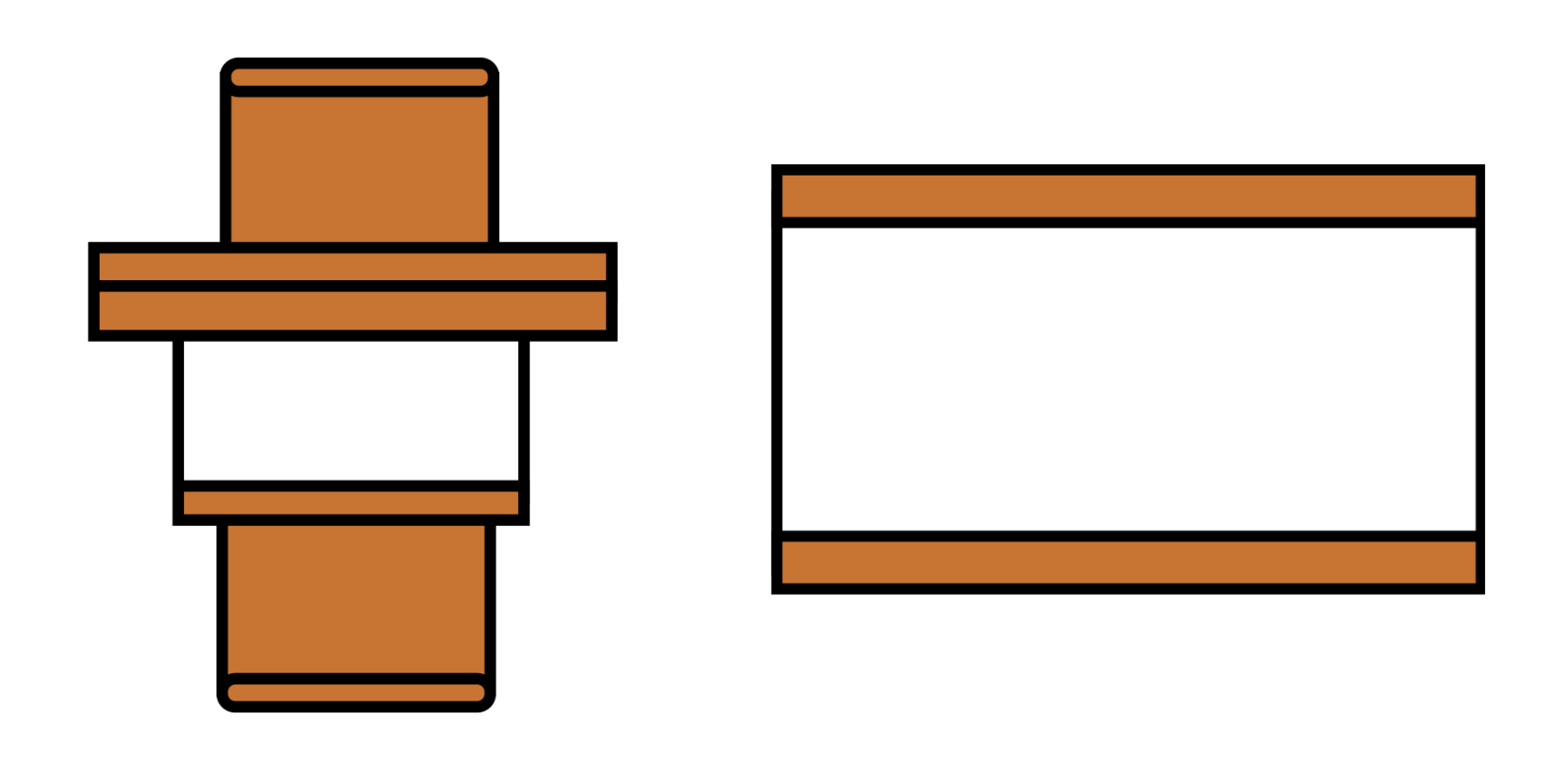

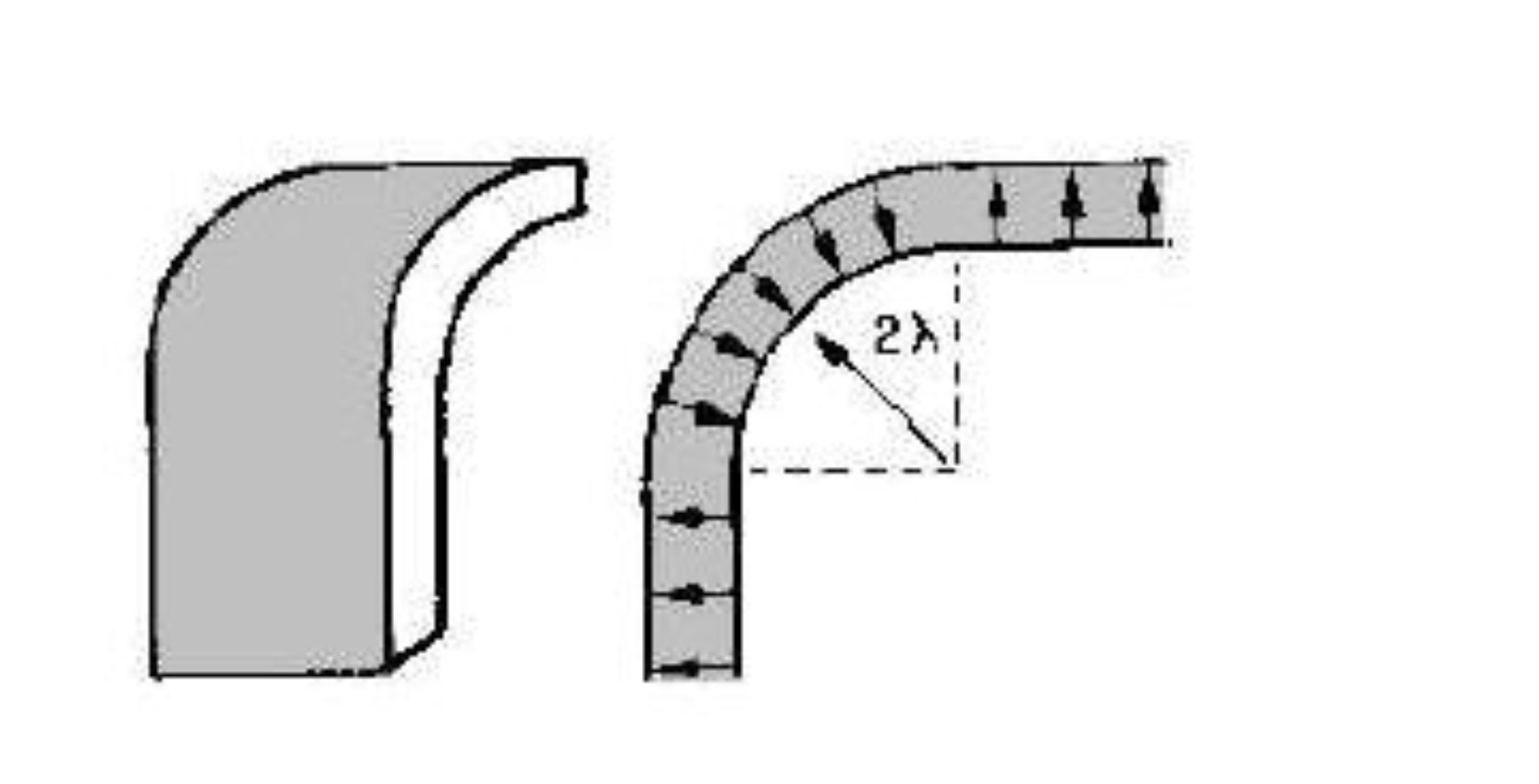

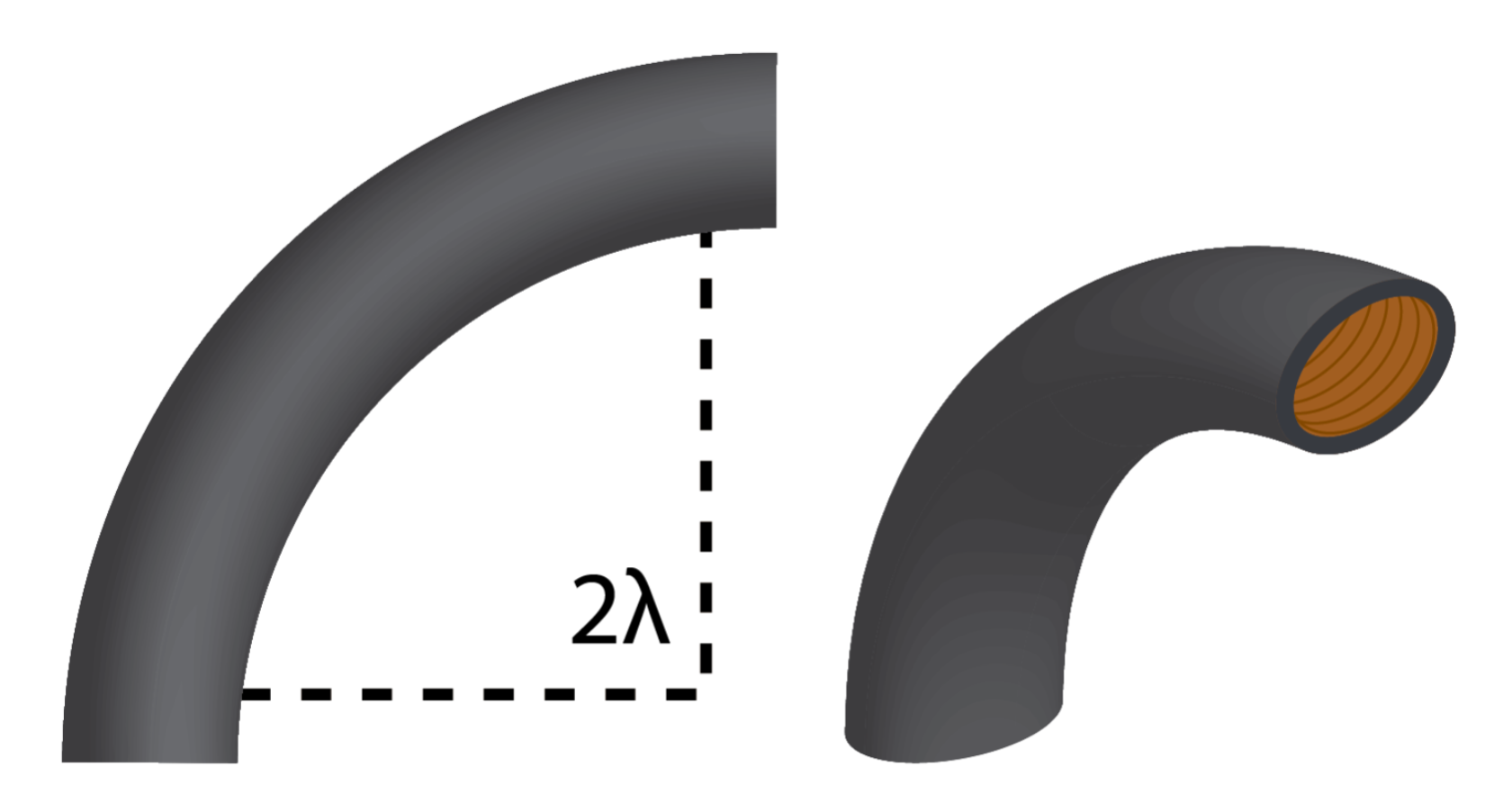

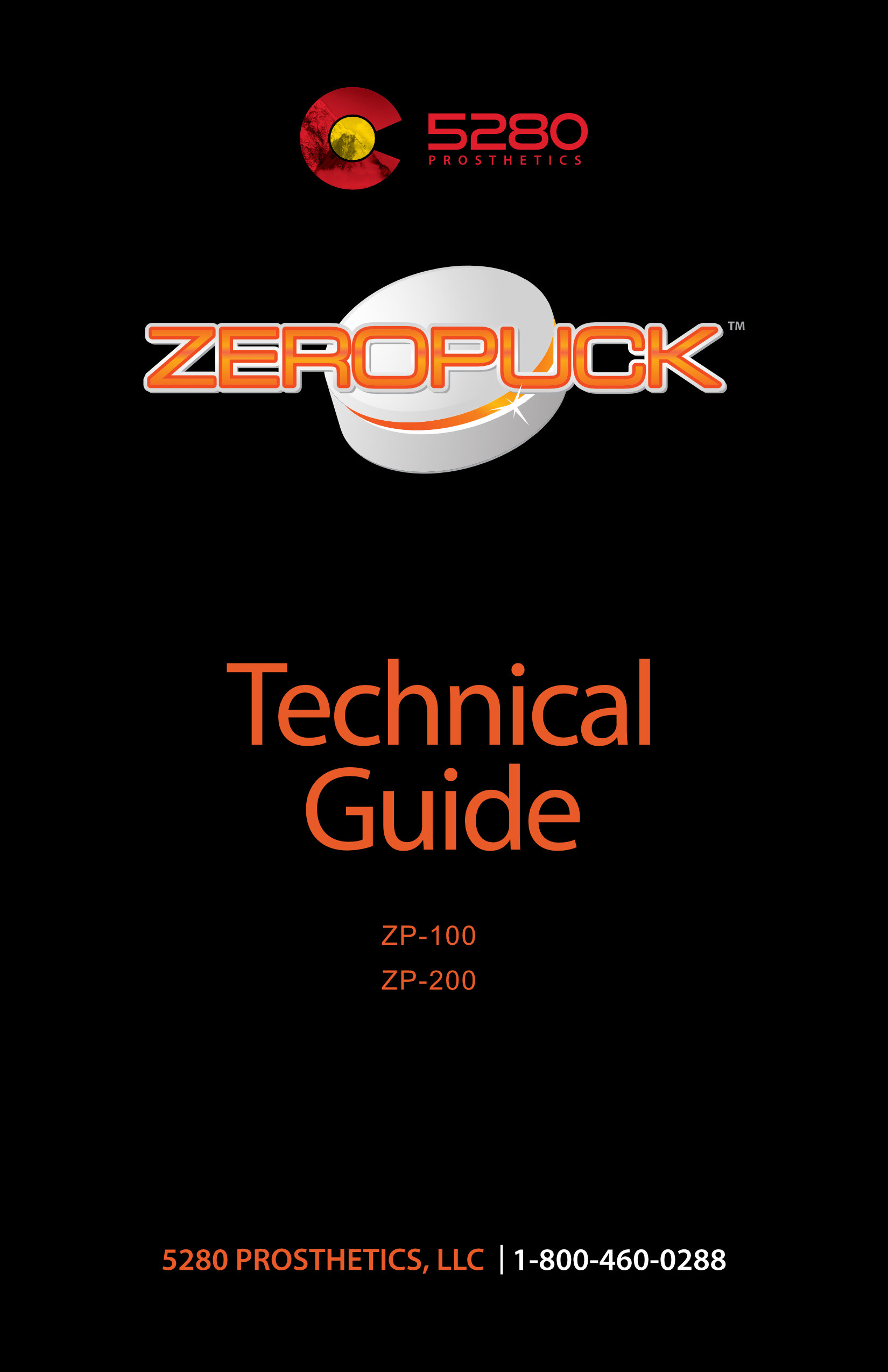

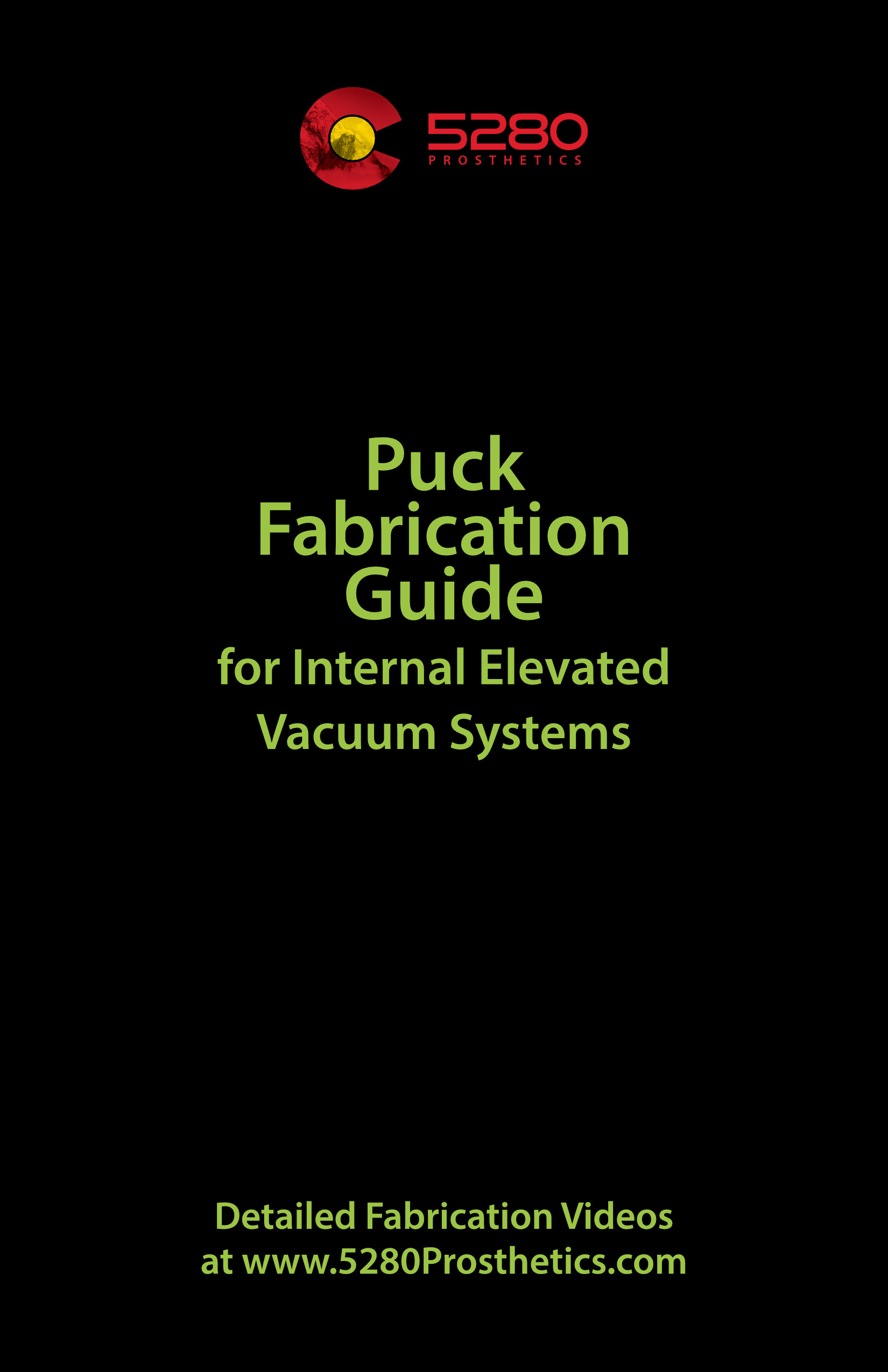

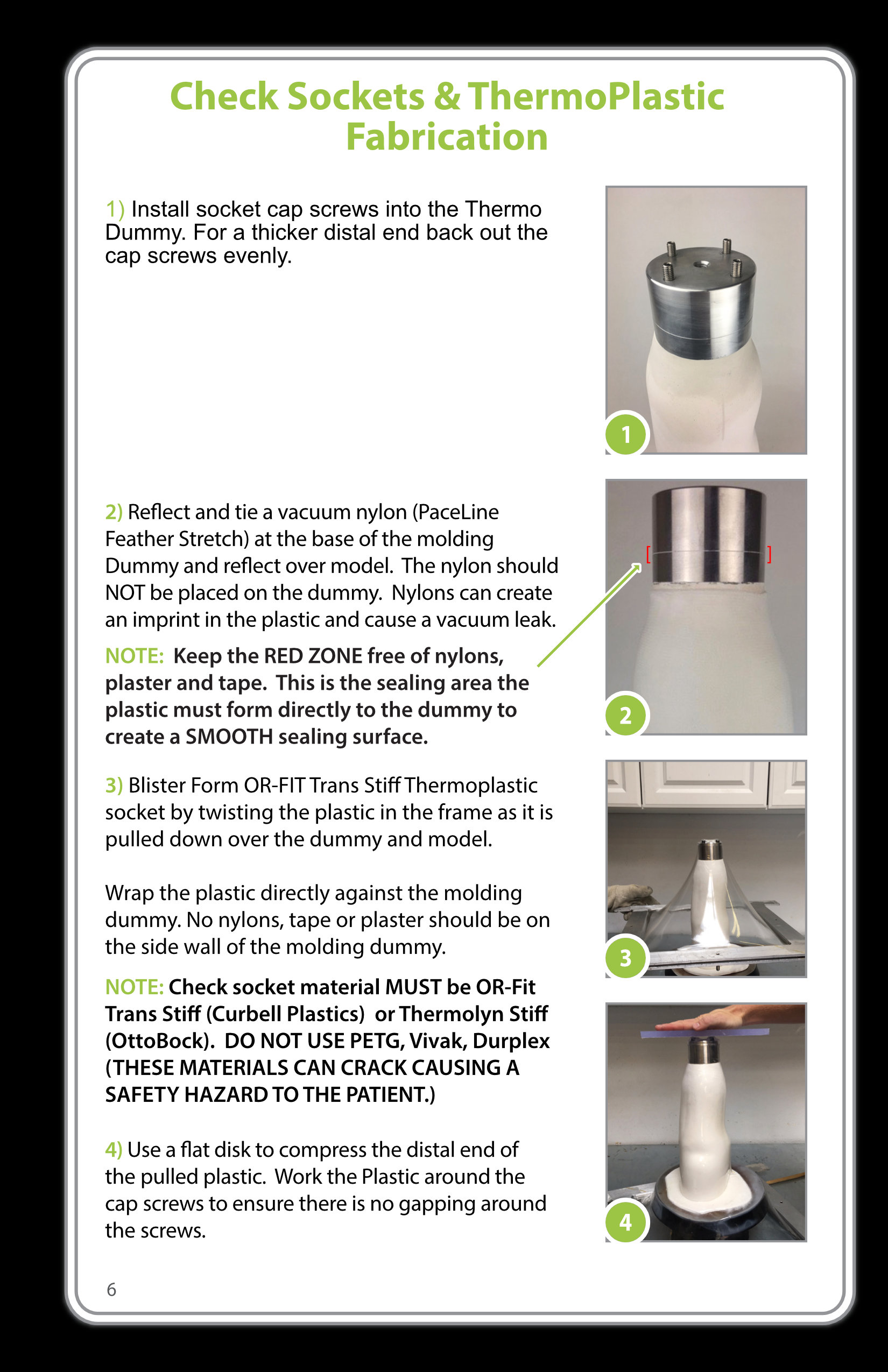

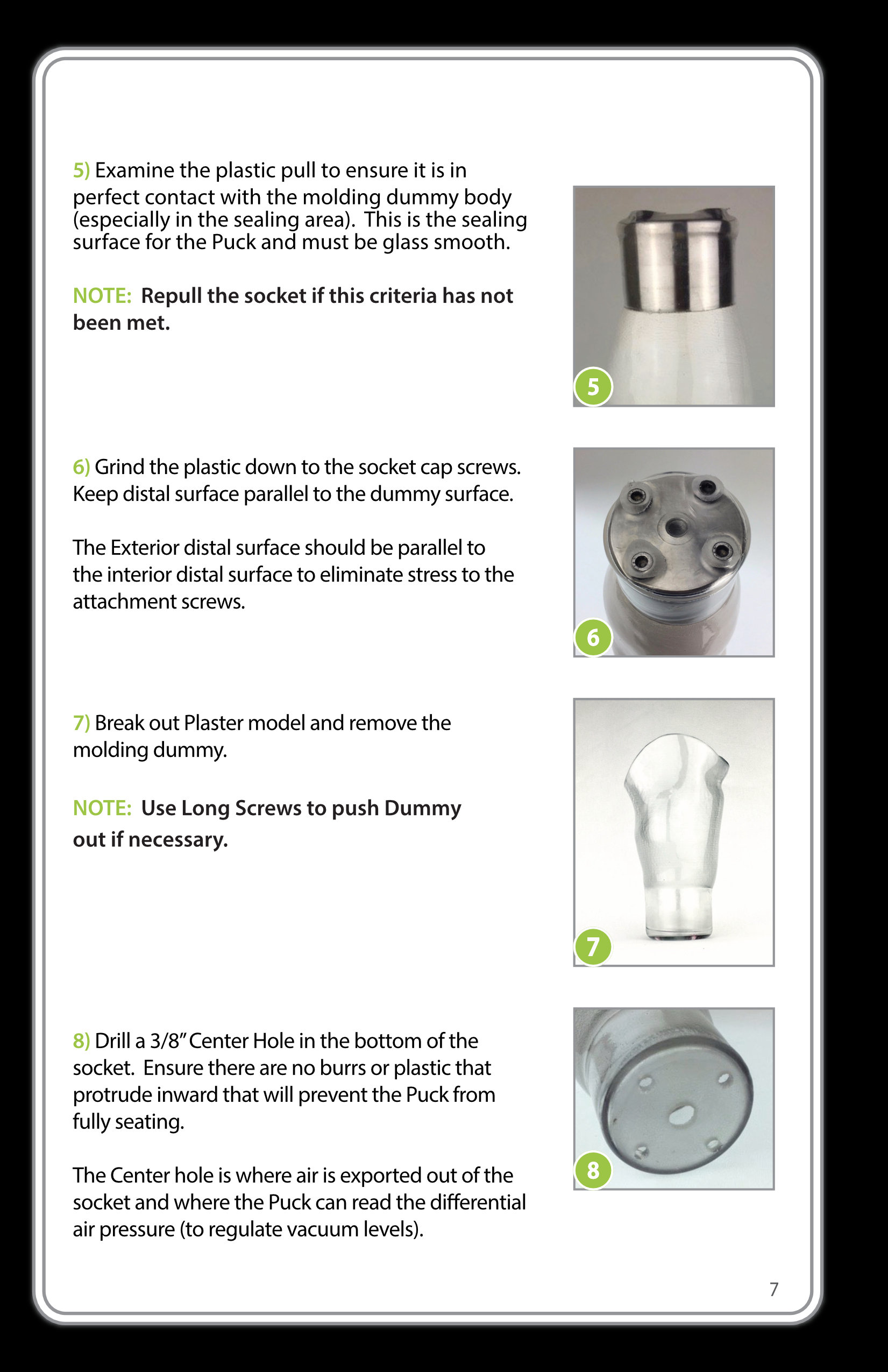

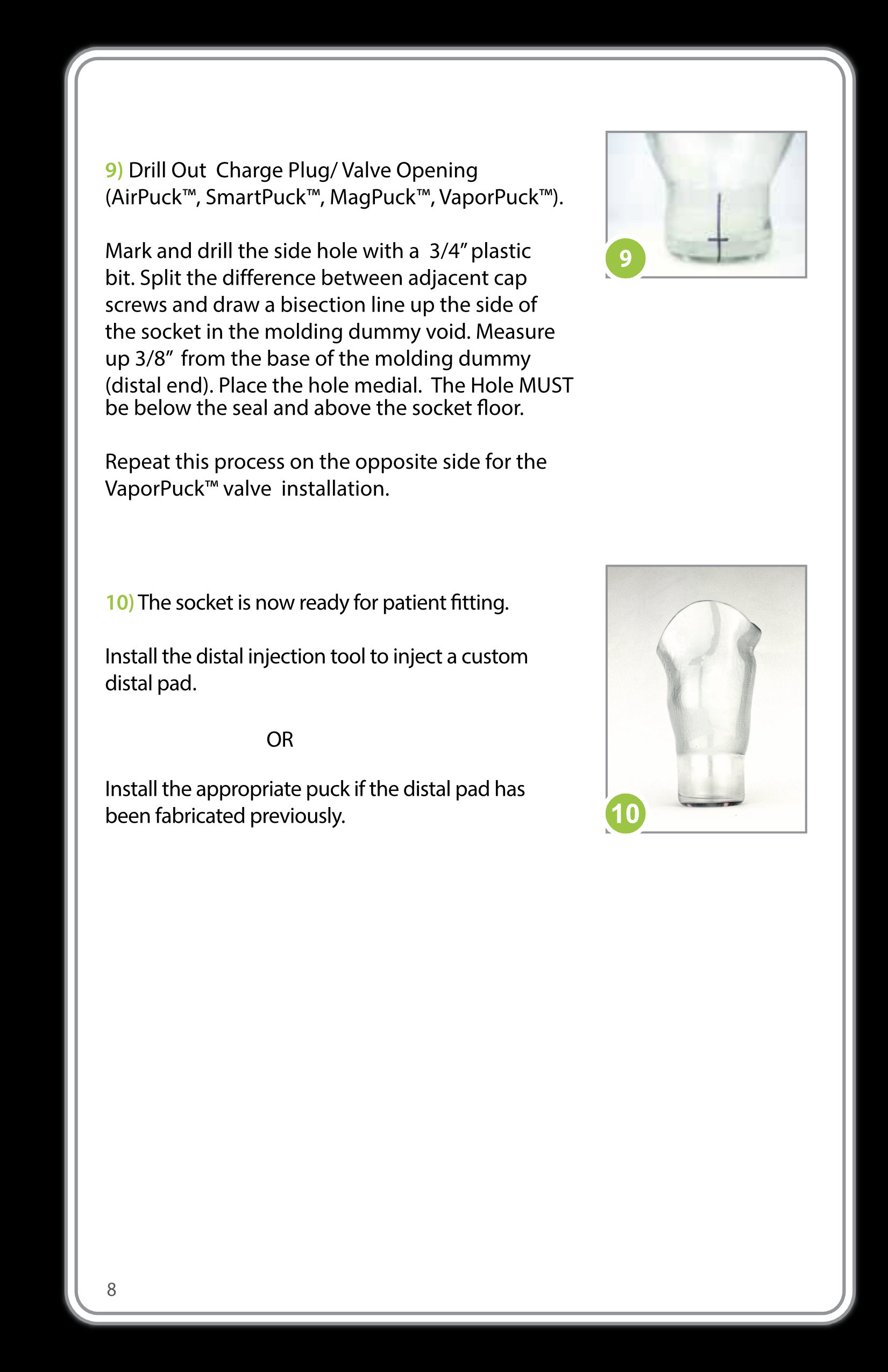

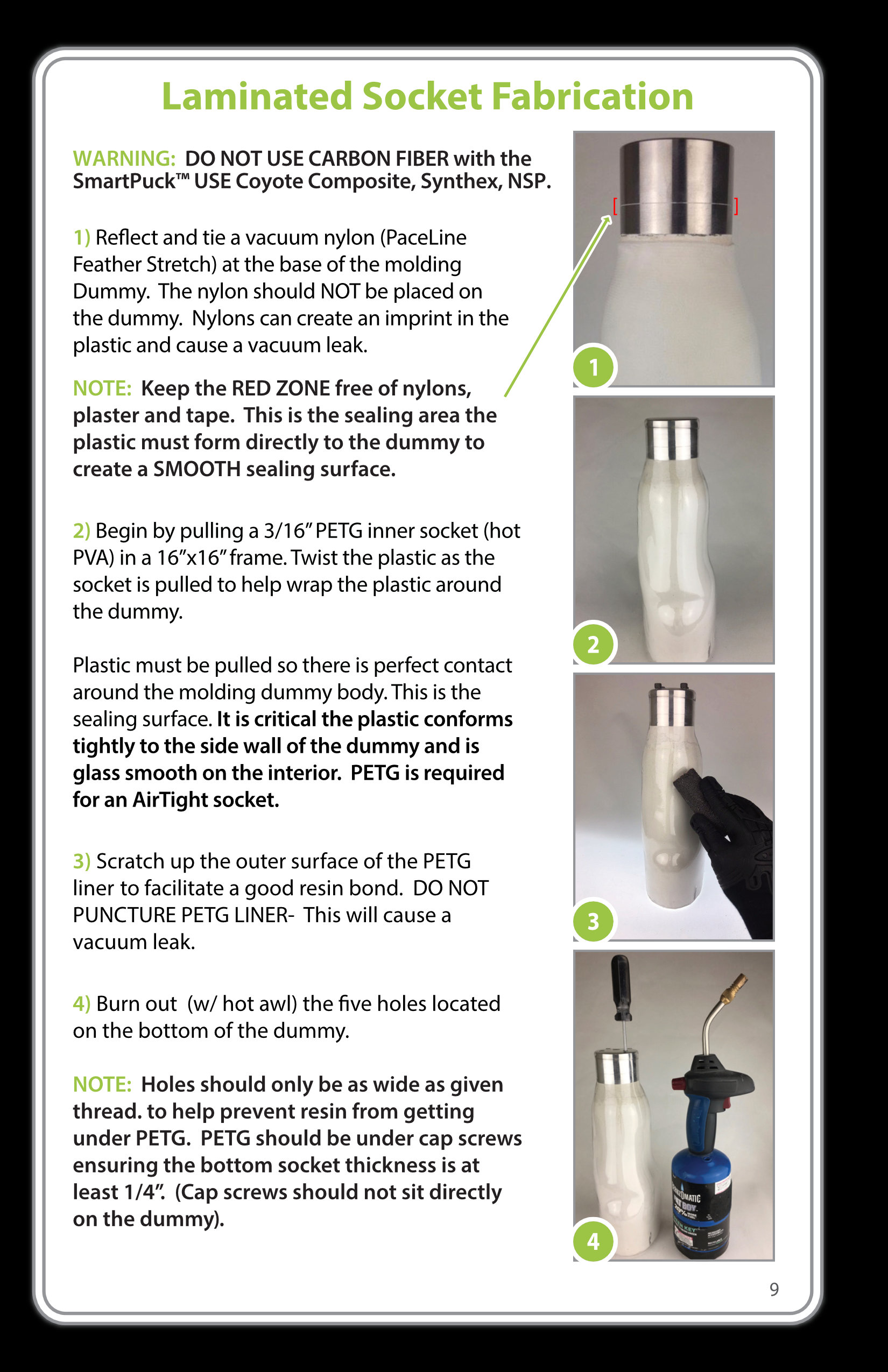

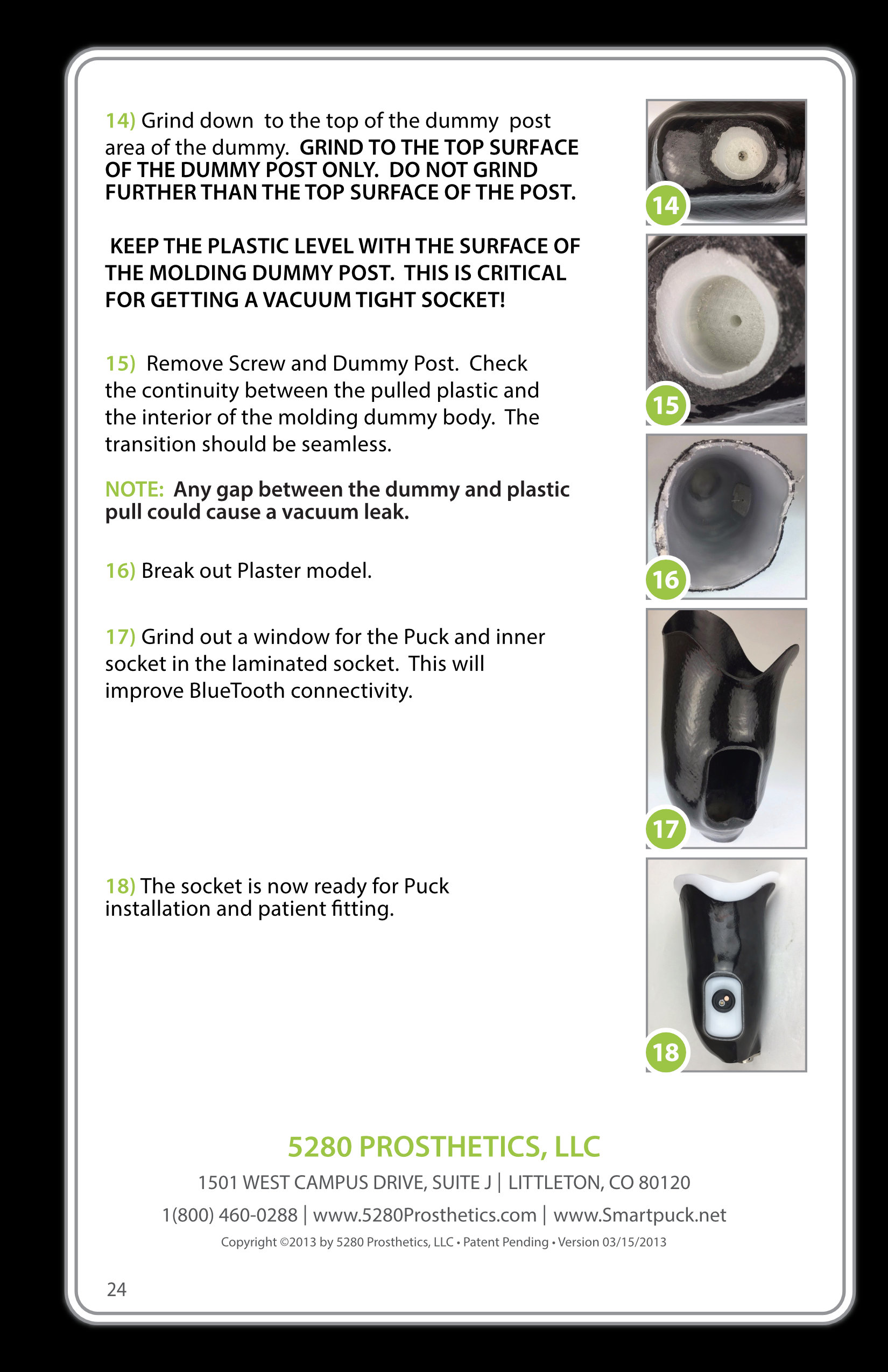

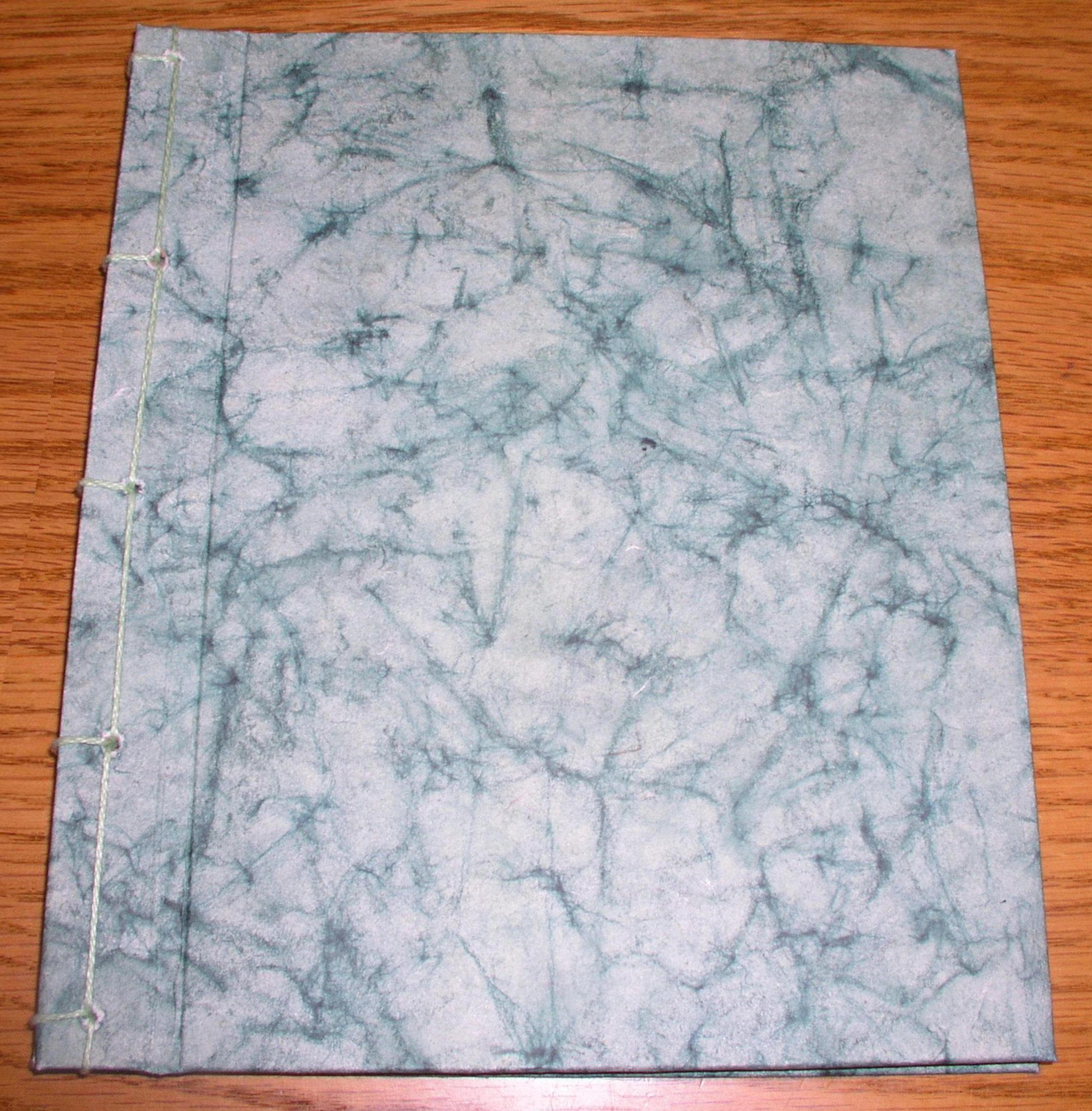

Puck Fabrication Guide

At Adaptec Prosthetics, I worked as a contractor redesigning several educational booklets.

The Puck Fabrication Guide focuses on the preparation of prosthetic sockets.

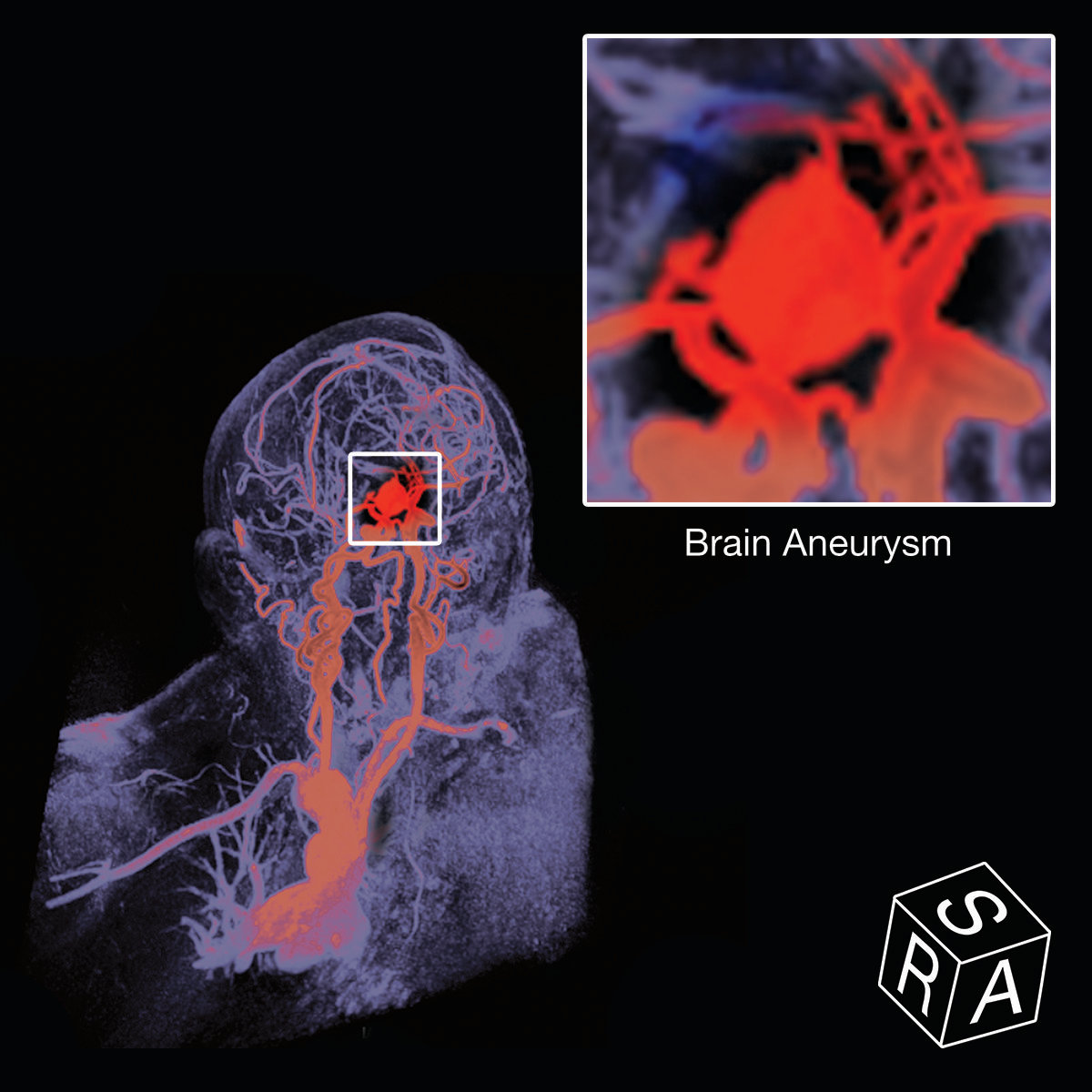

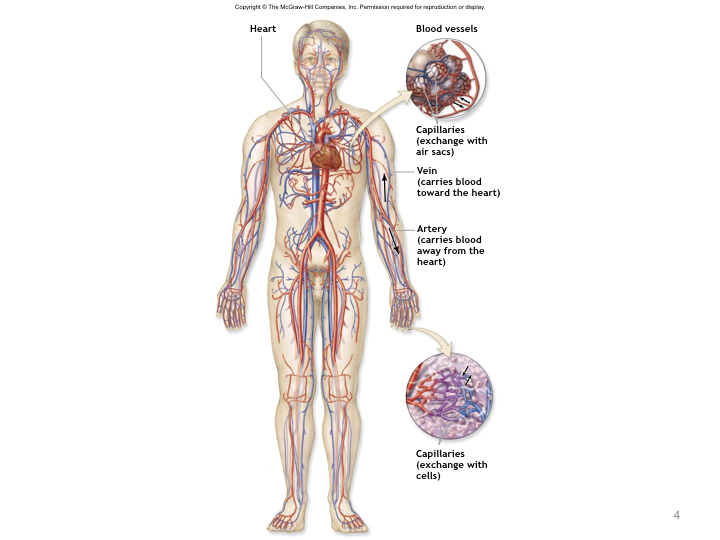

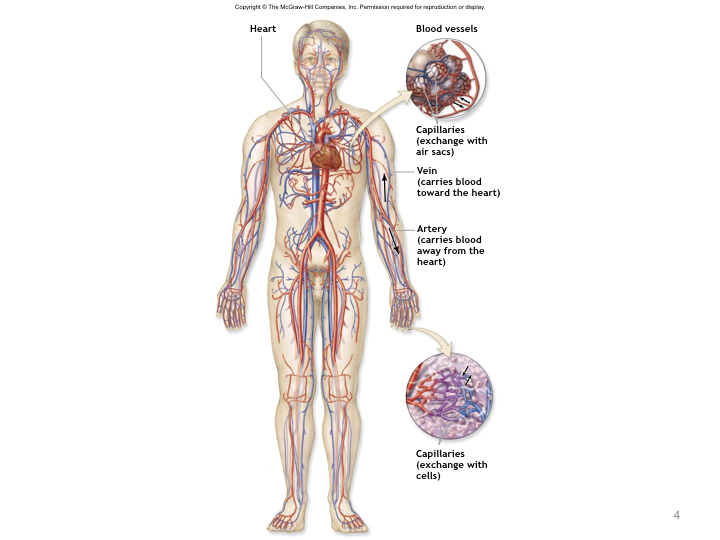

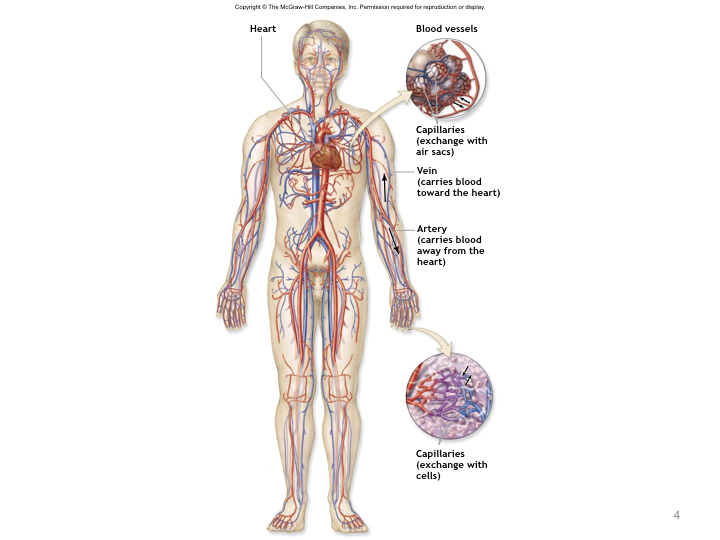

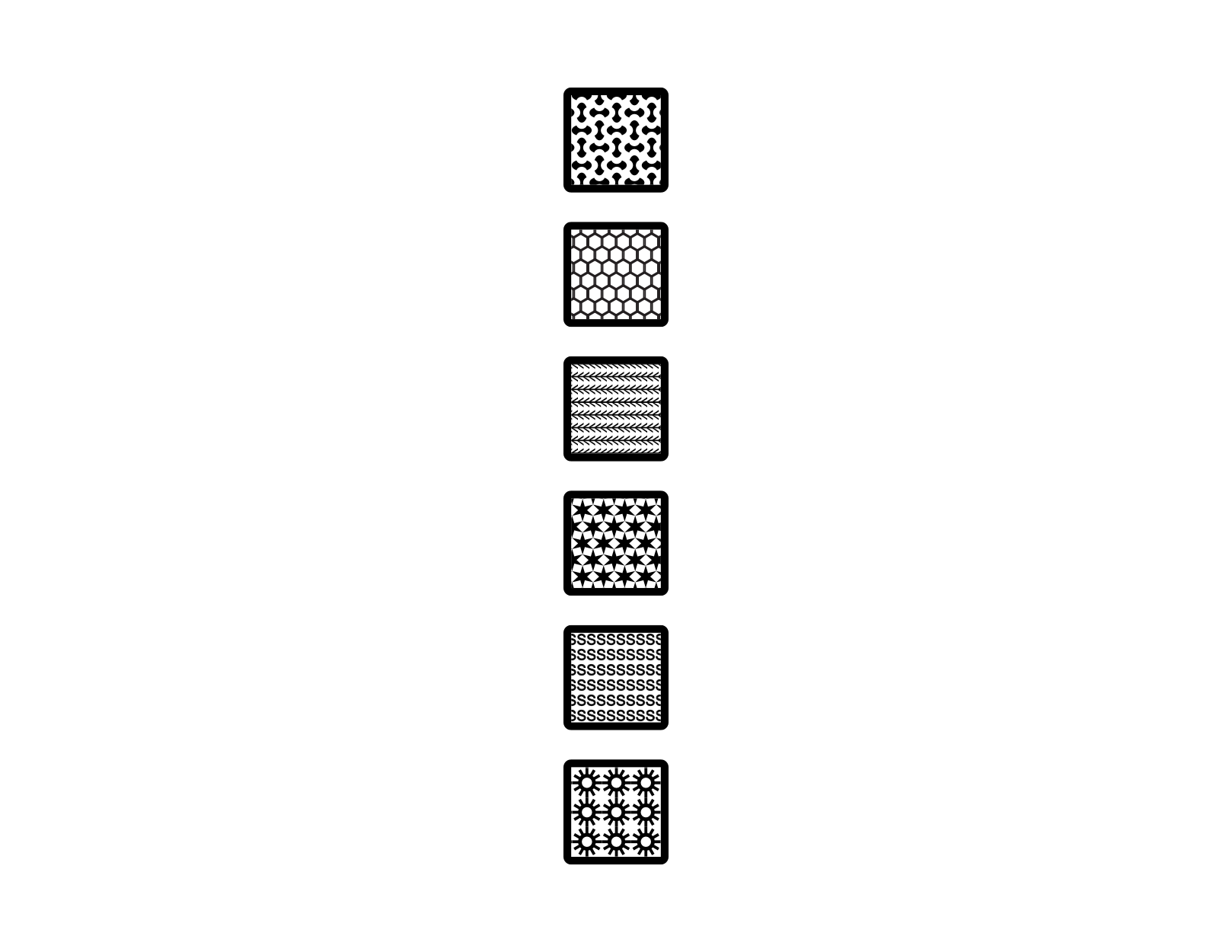

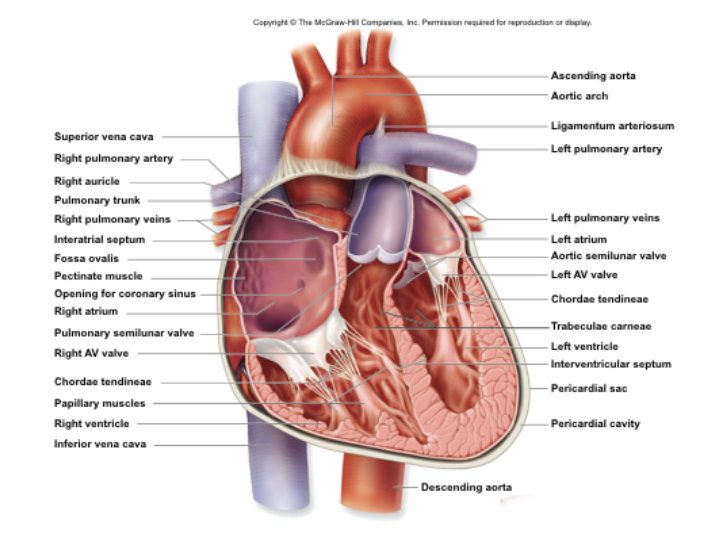

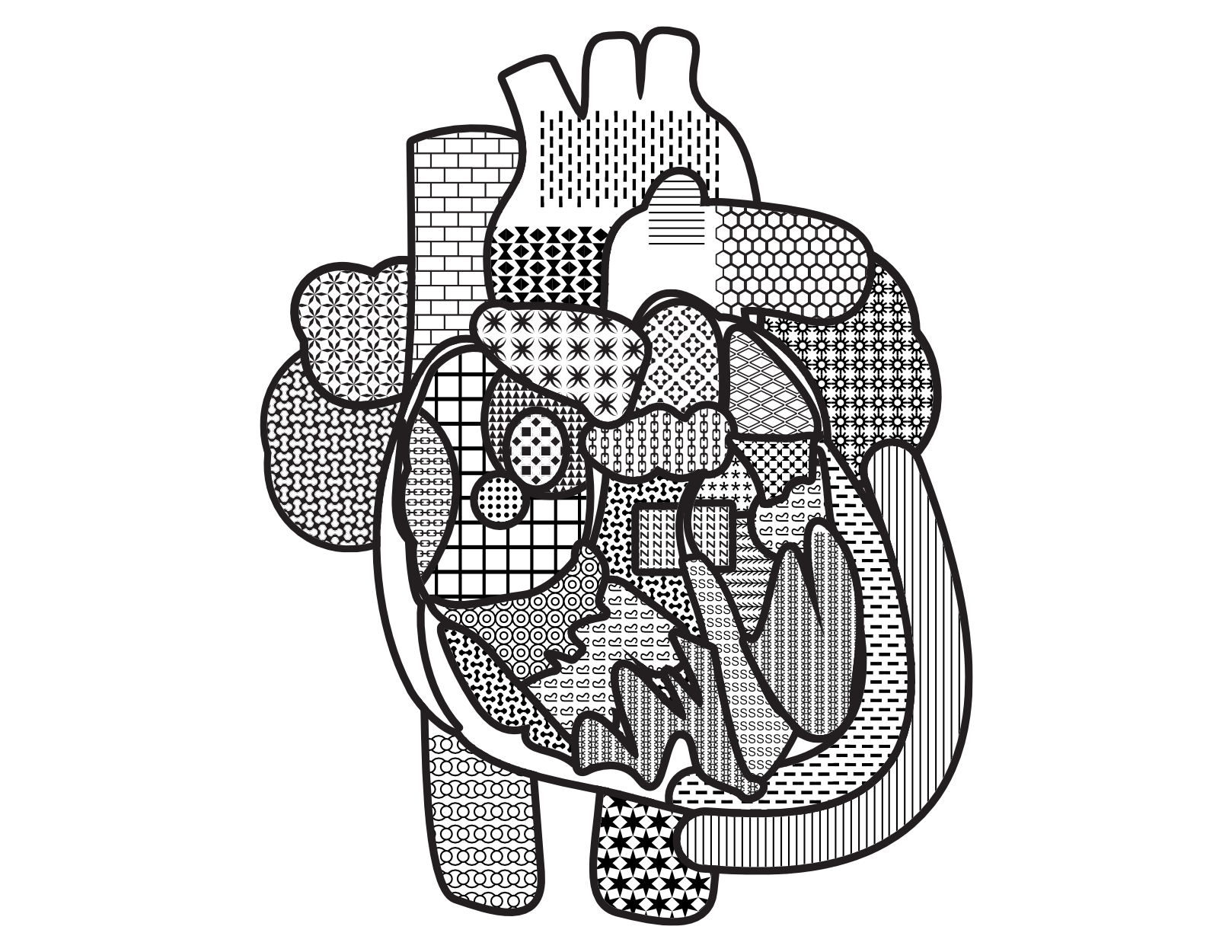

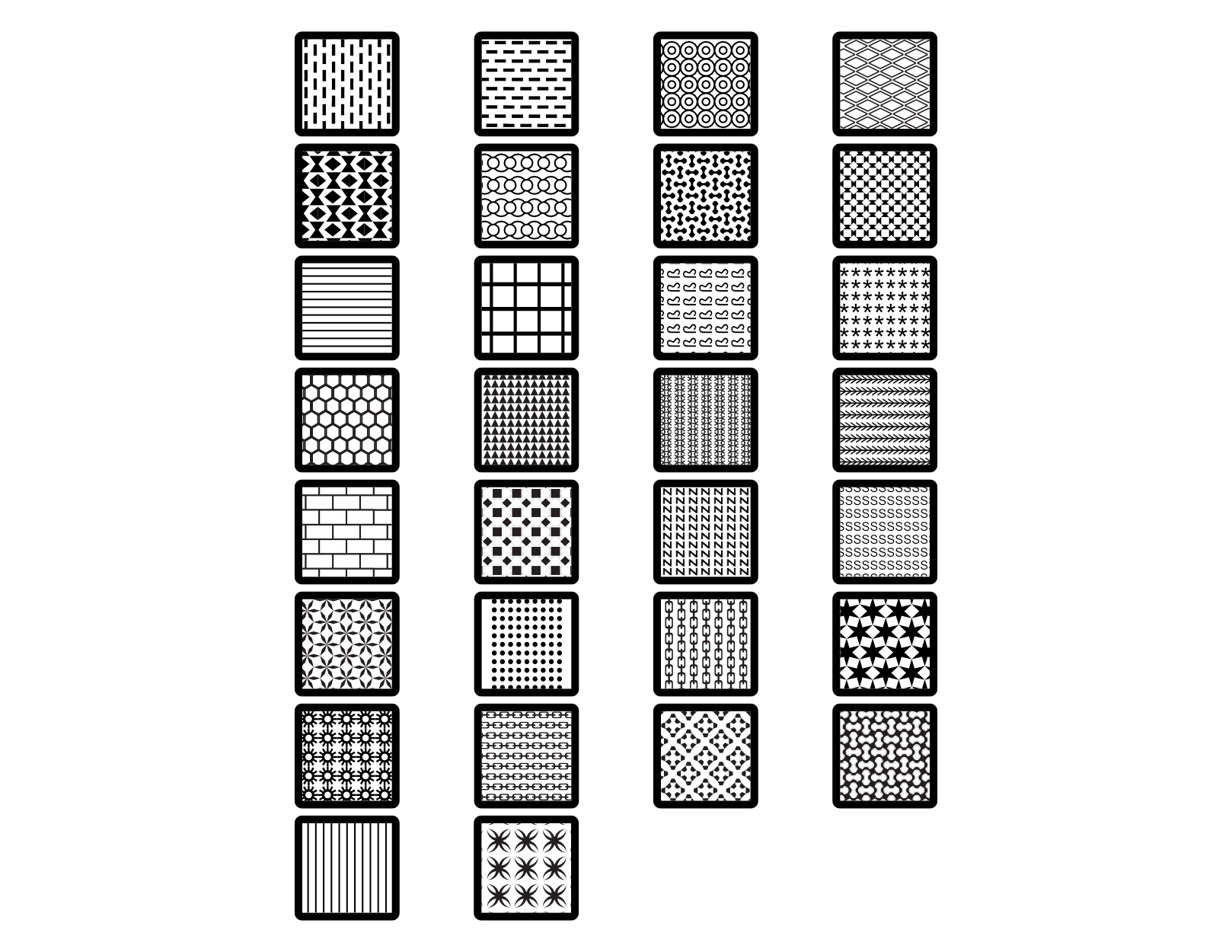

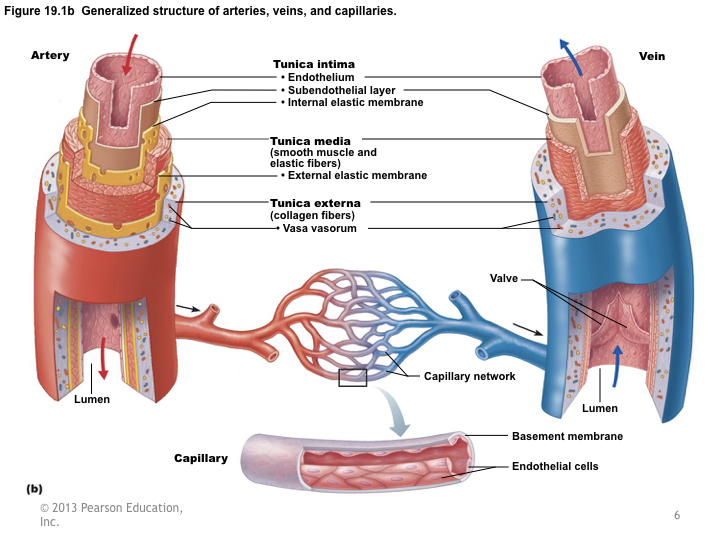

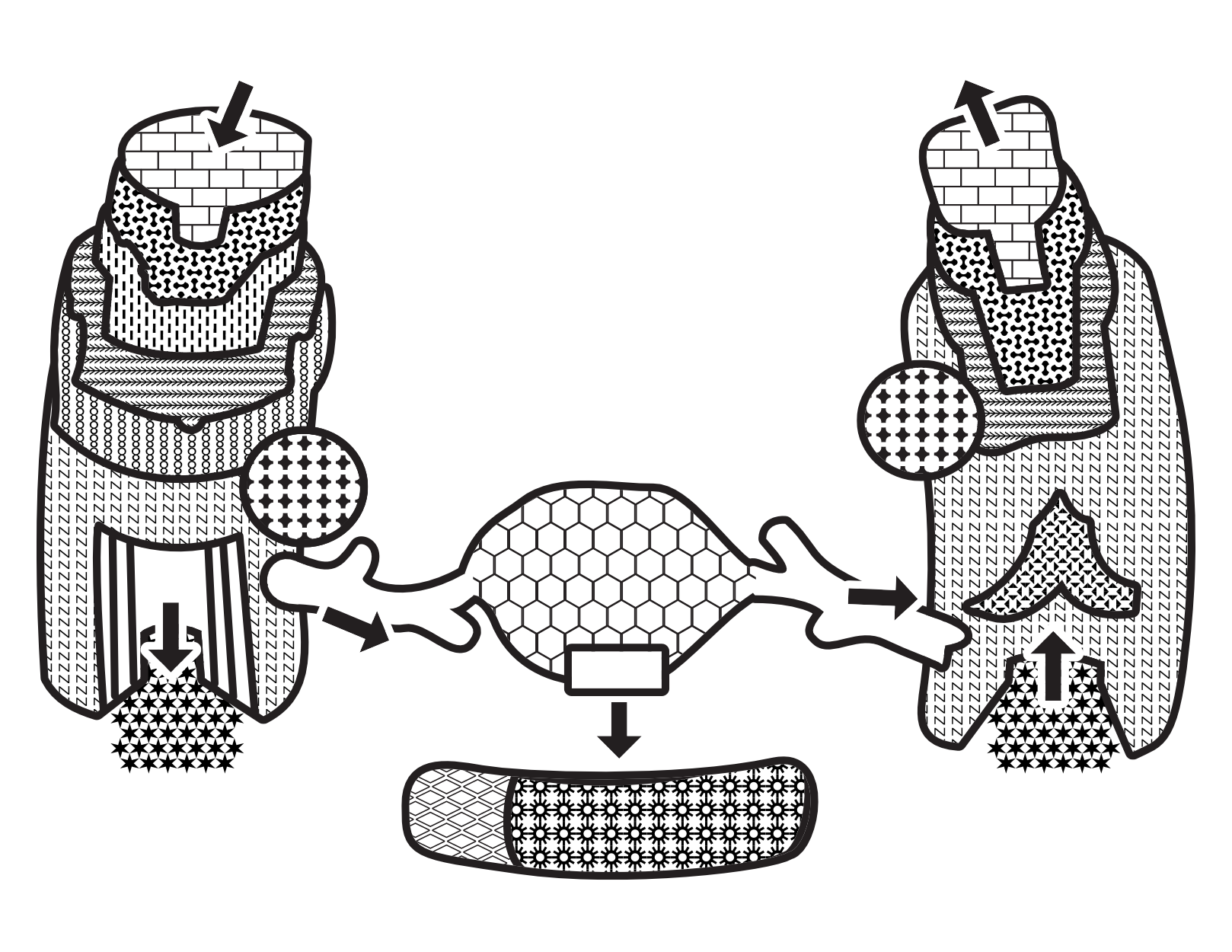

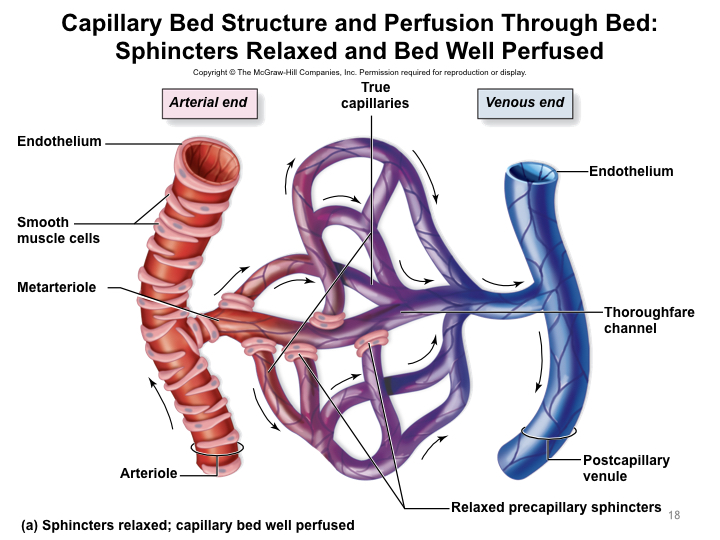

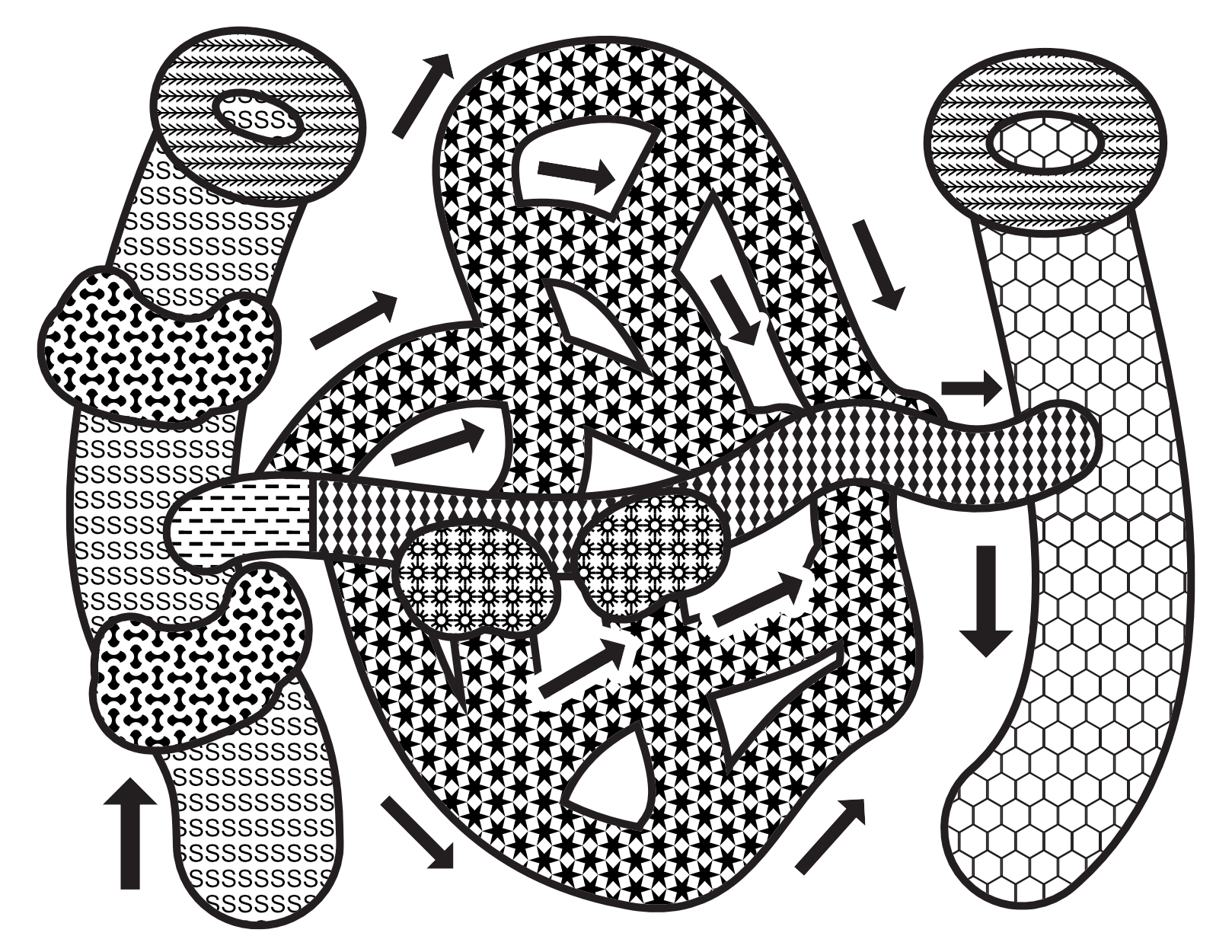

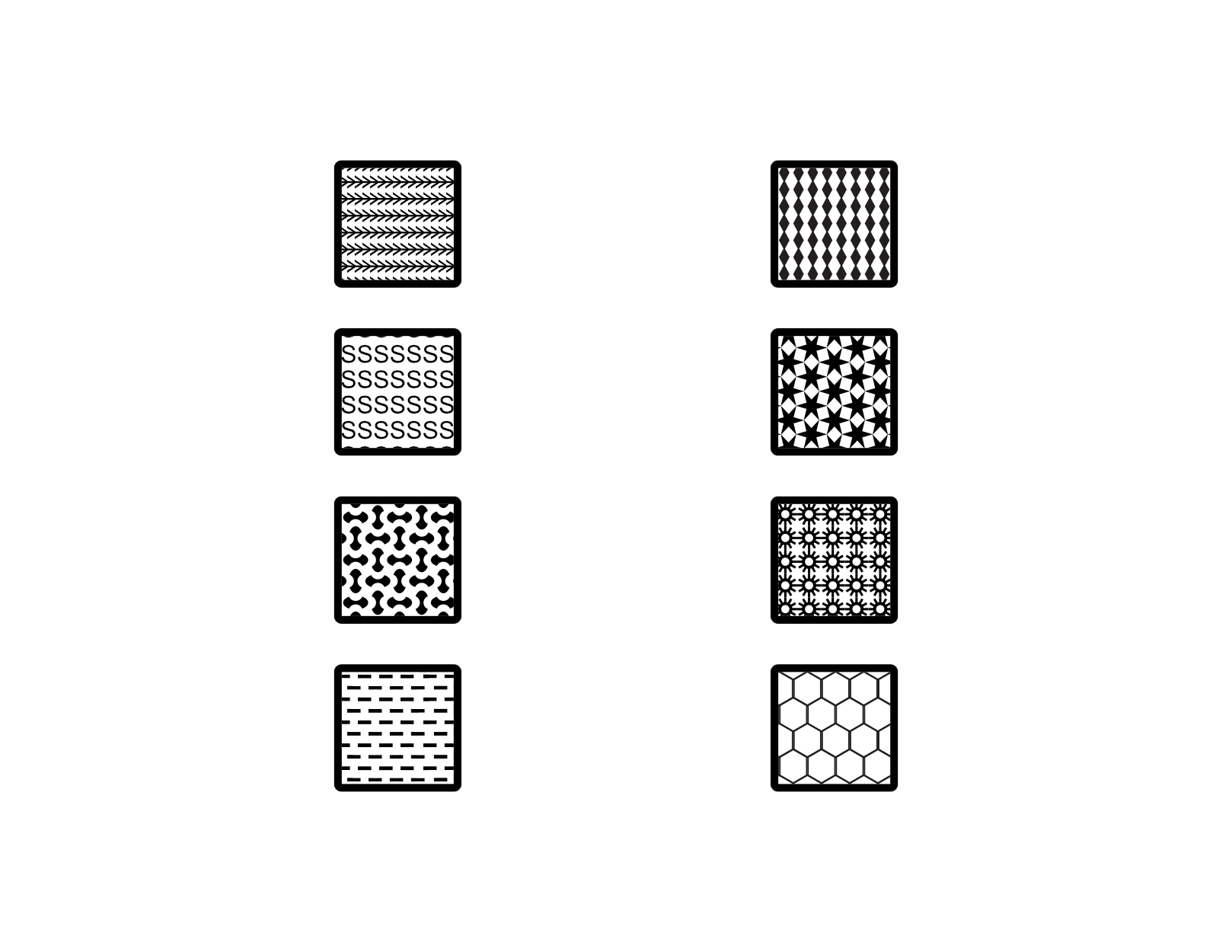

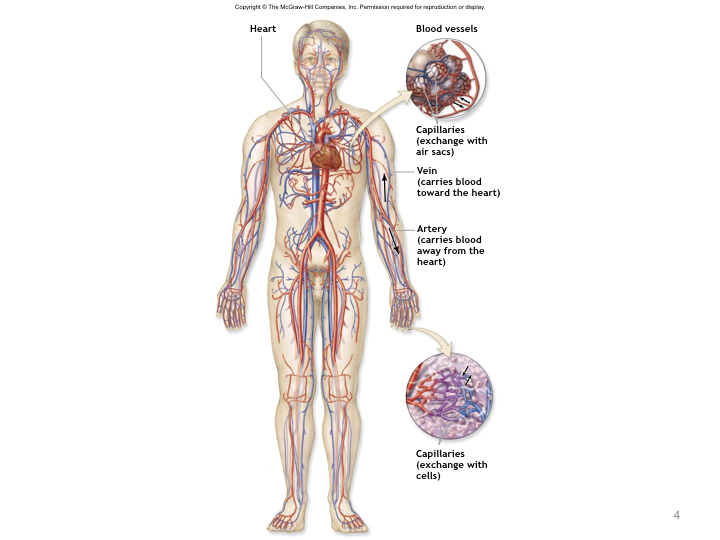

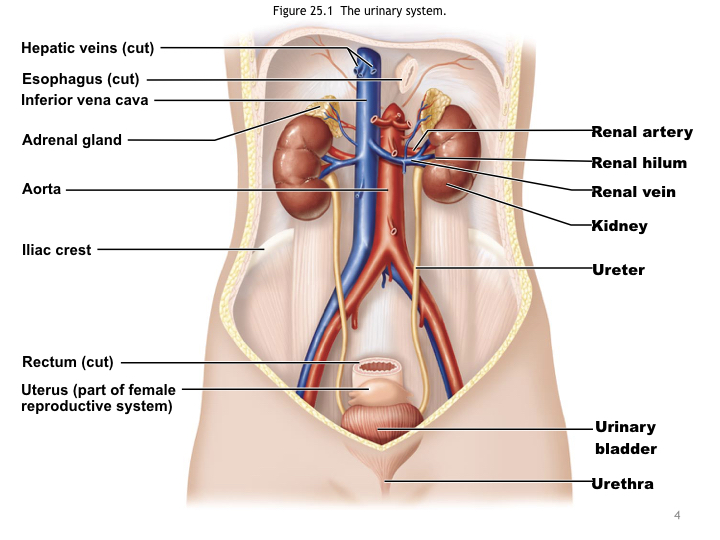

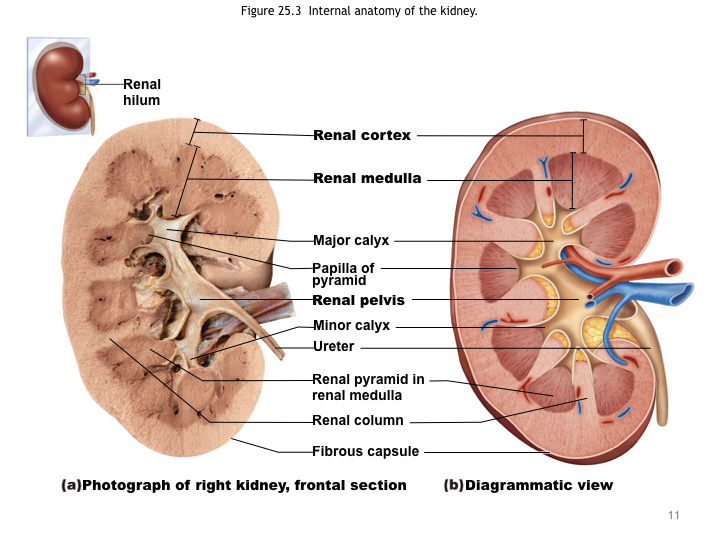

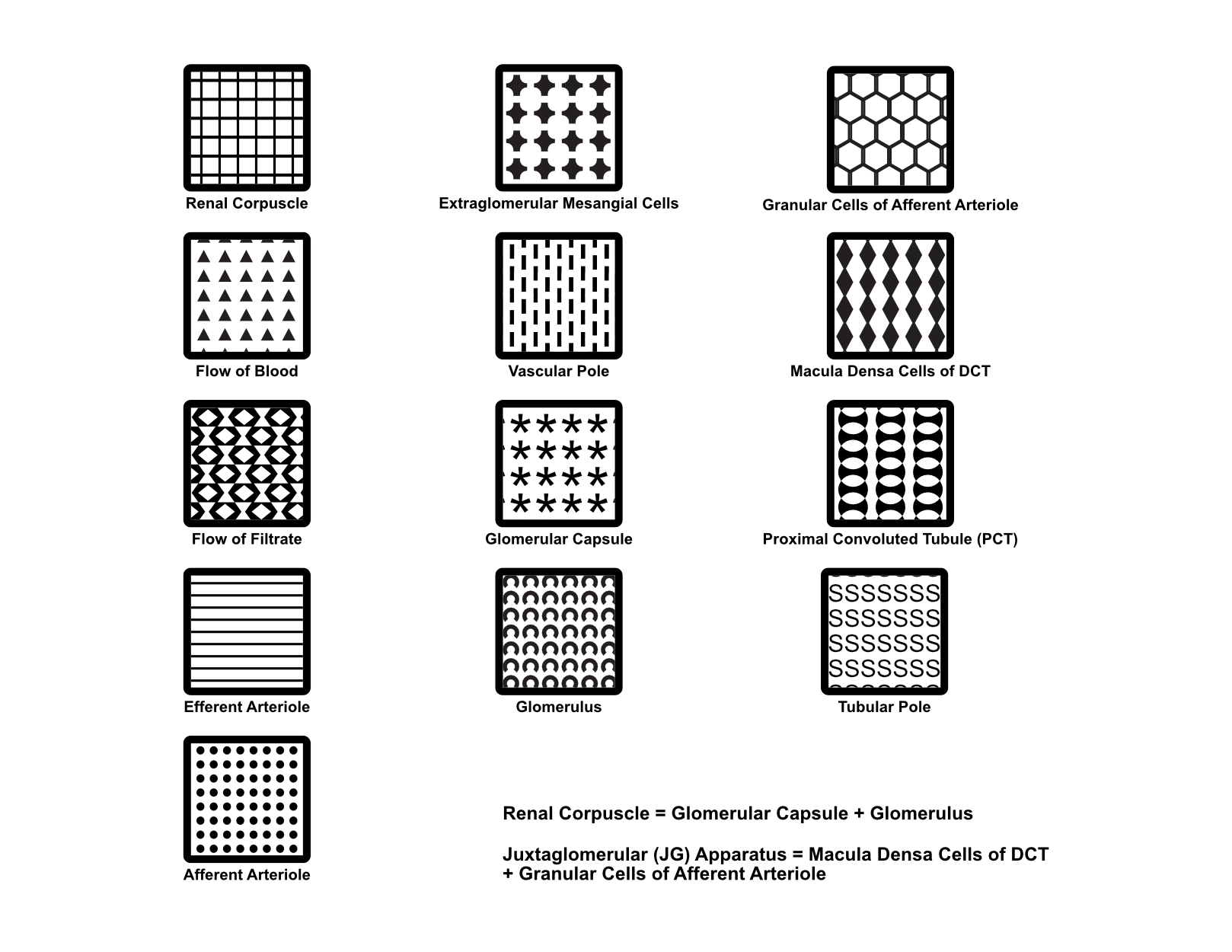

Circulatory System

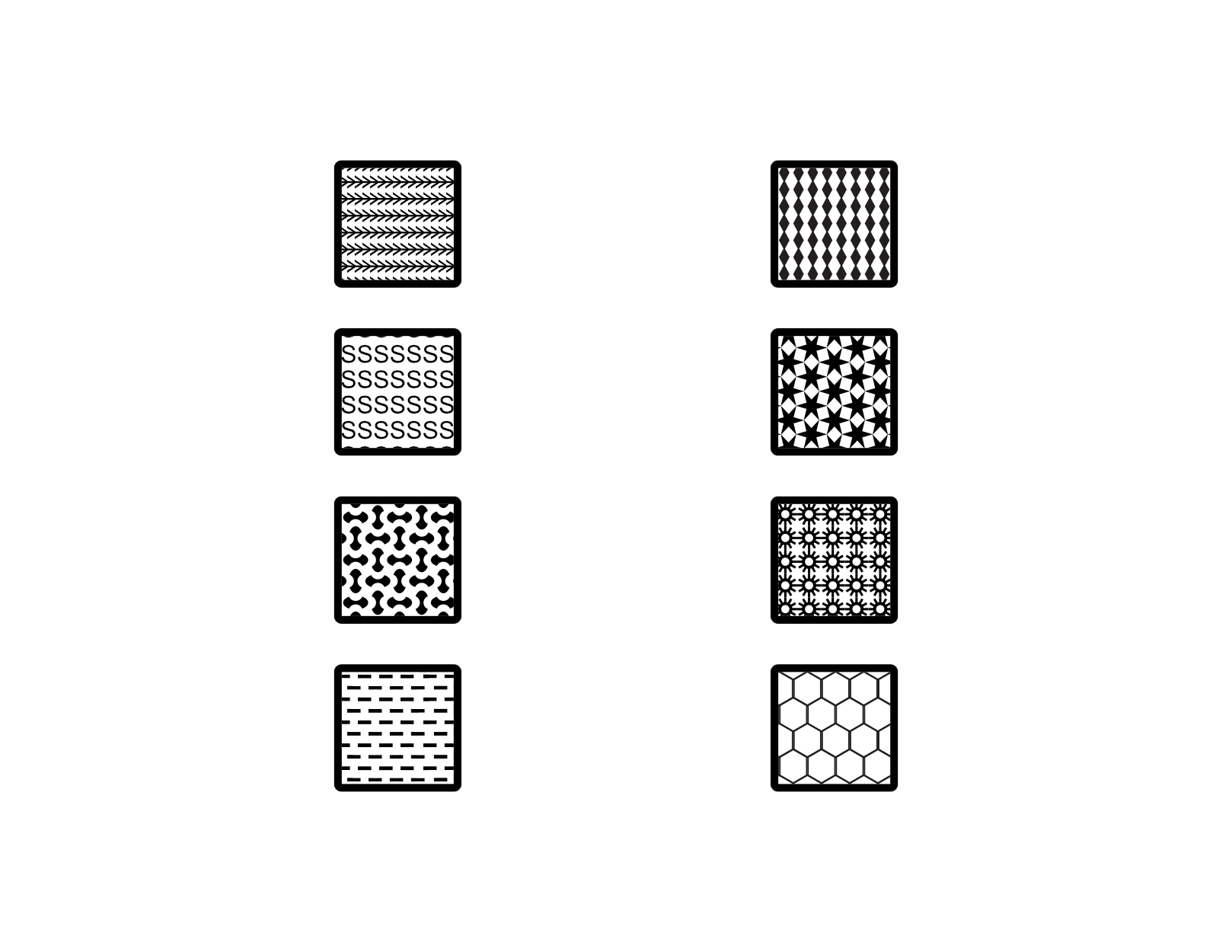

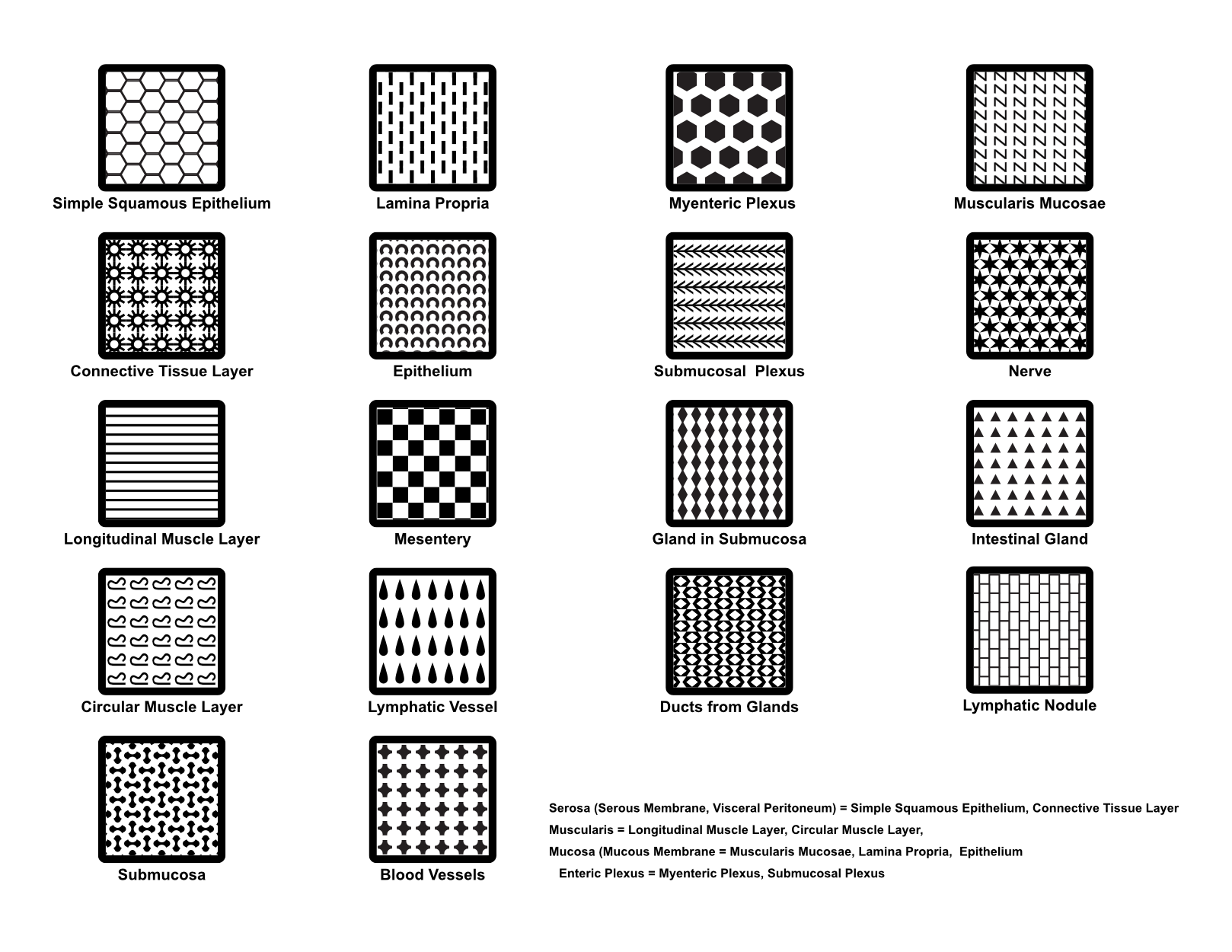

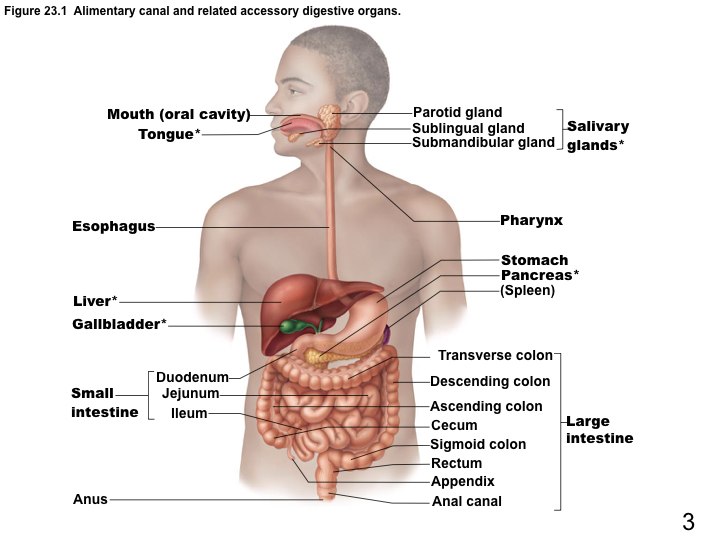

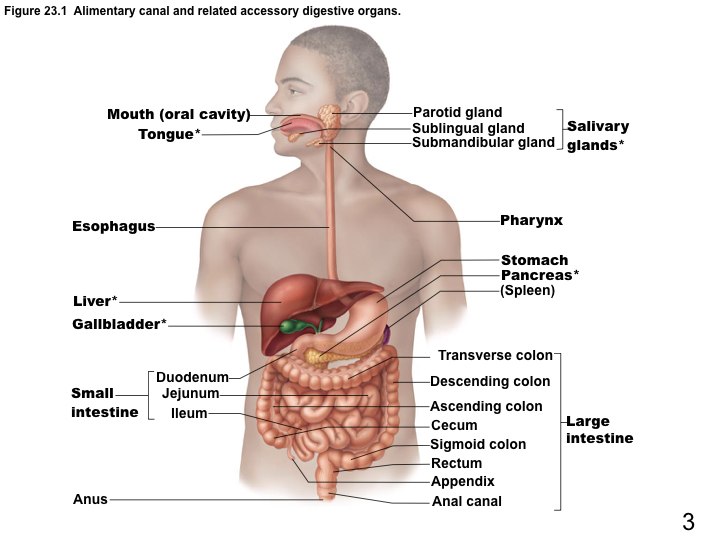

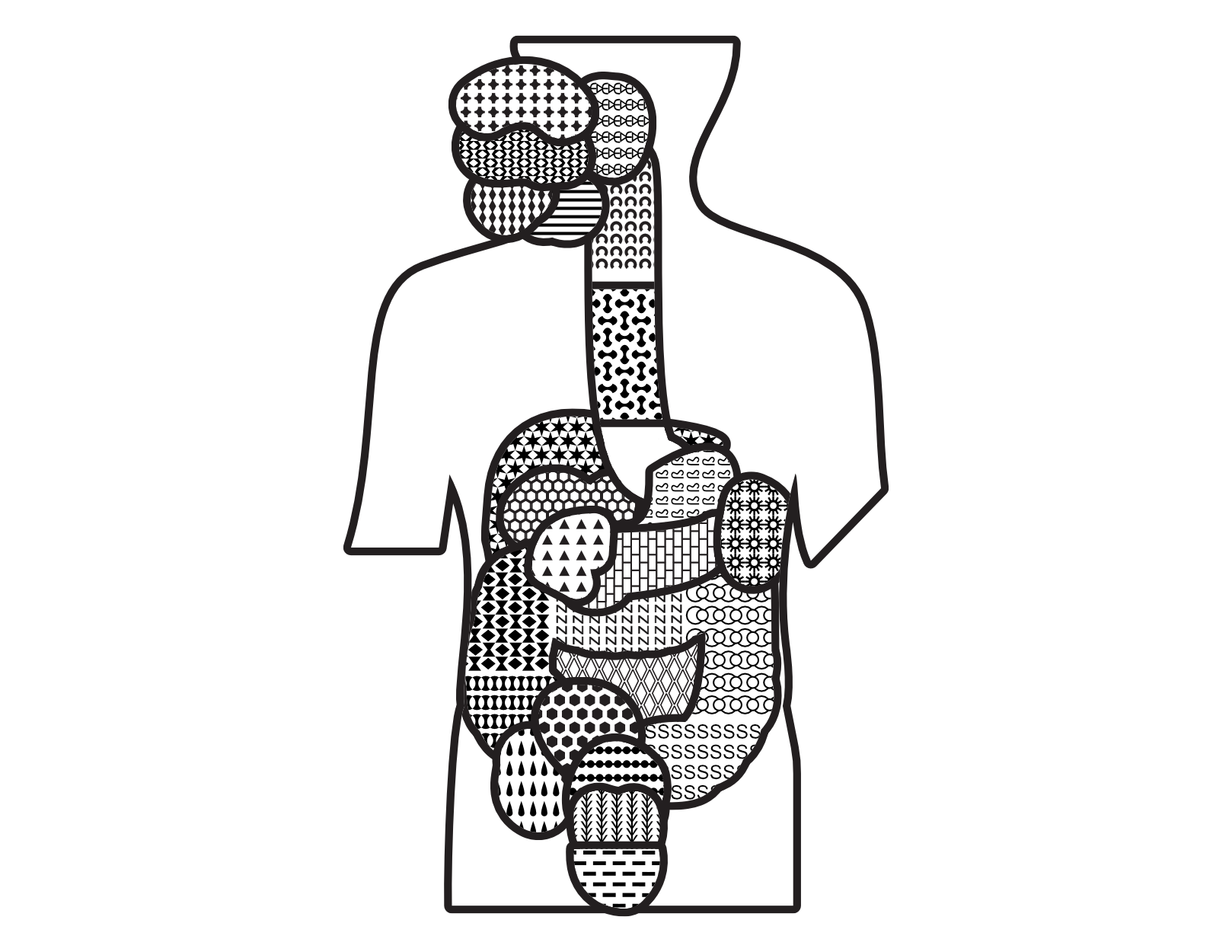

I did some contract work at MSU Denver creating Tactile Graphics. My employer would send me PowerPoints with images. I simplified the images, creating different patterns for different labels. The patterns are printed as raised graphics on swell paper. The blind students can feel them and understand the illustration using a key.

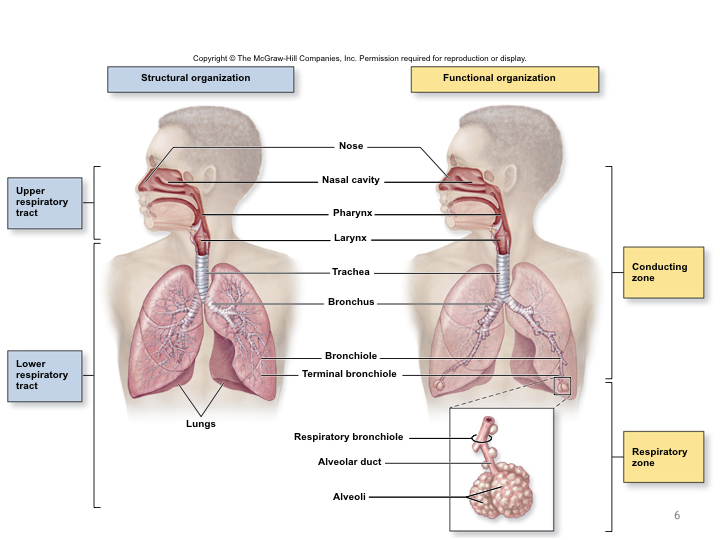

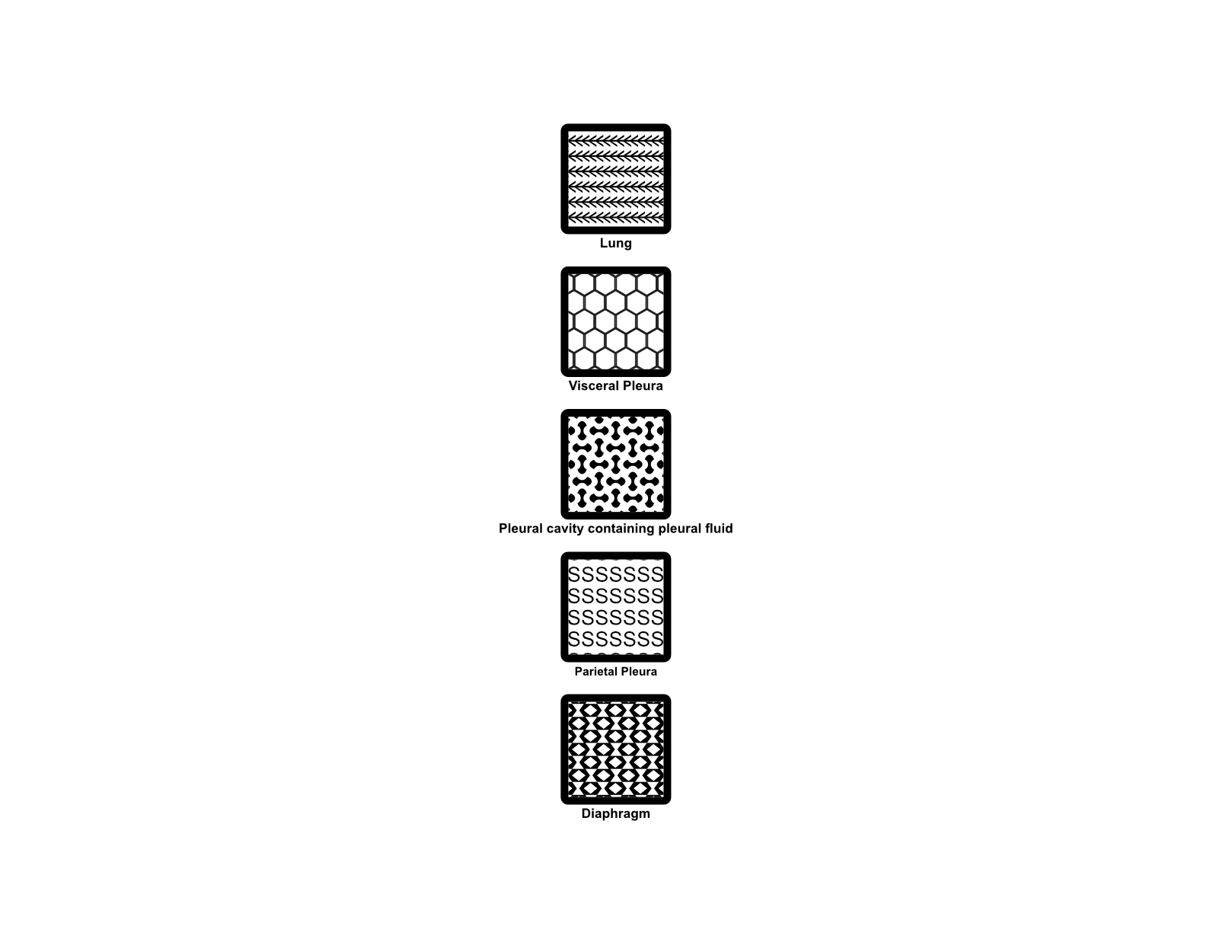

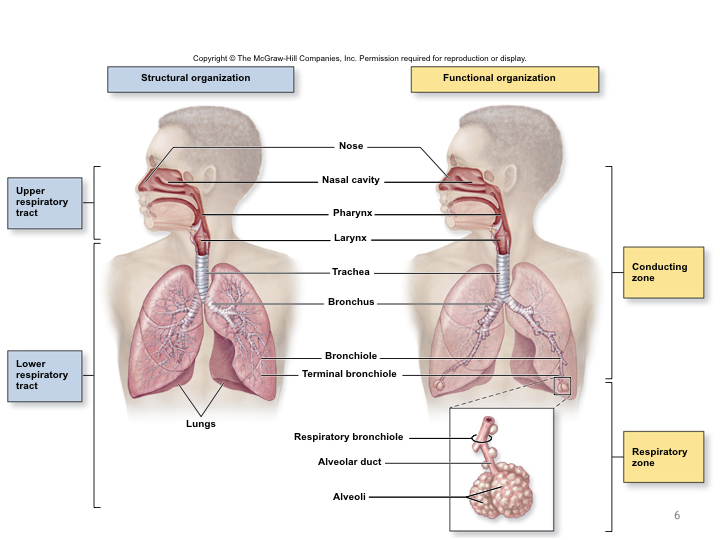

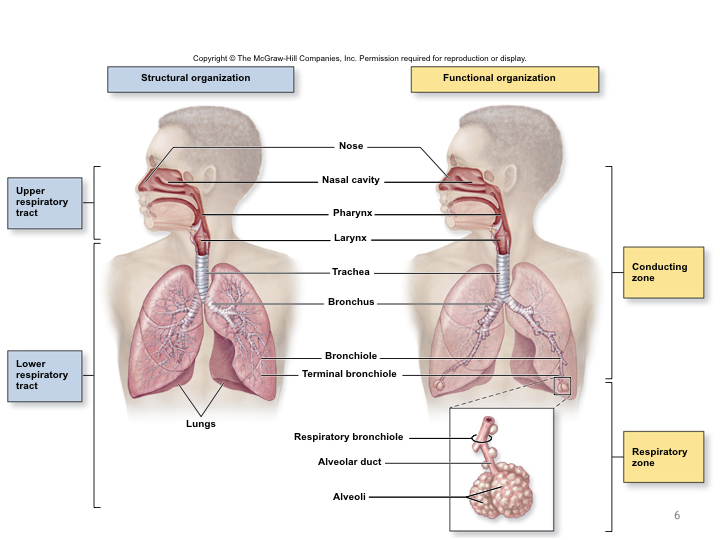

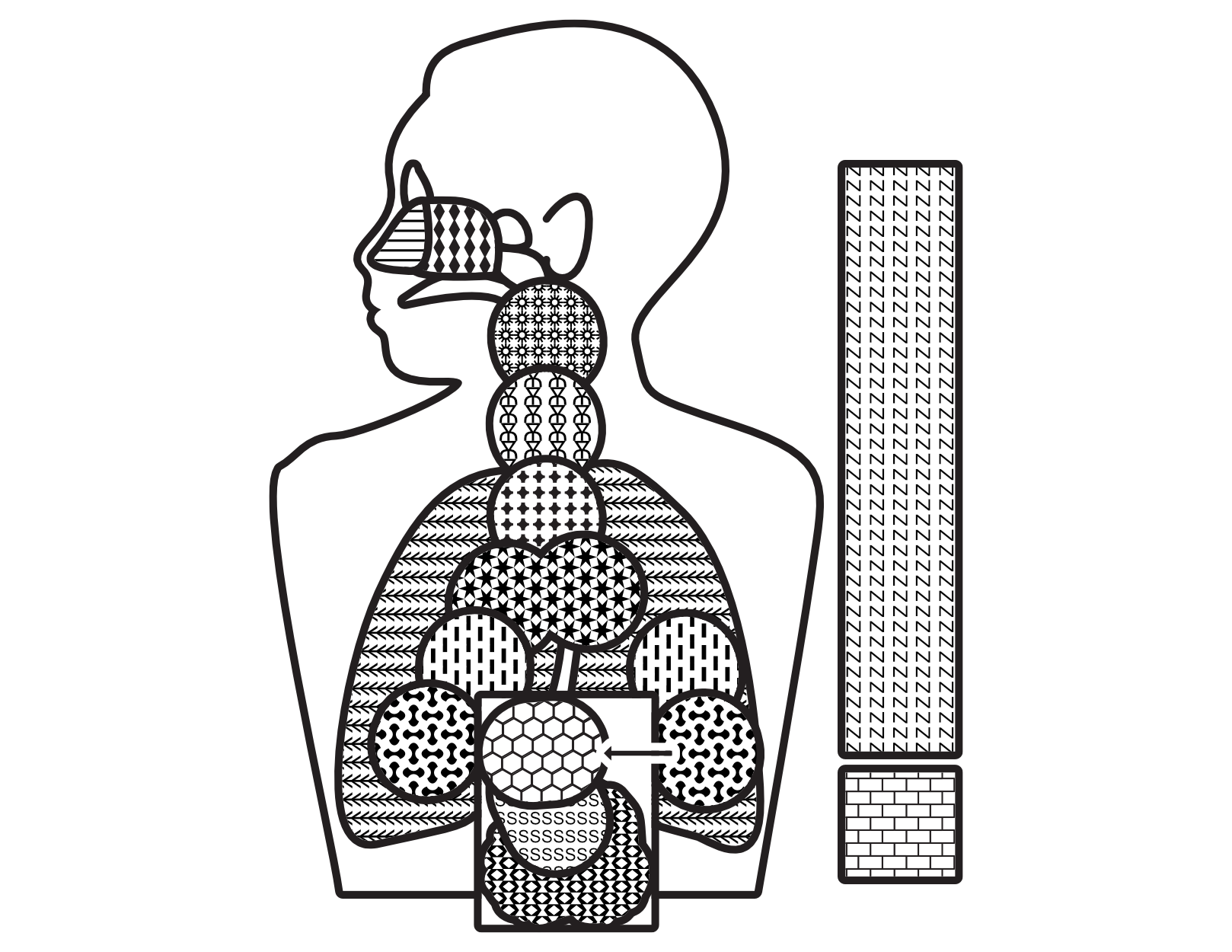

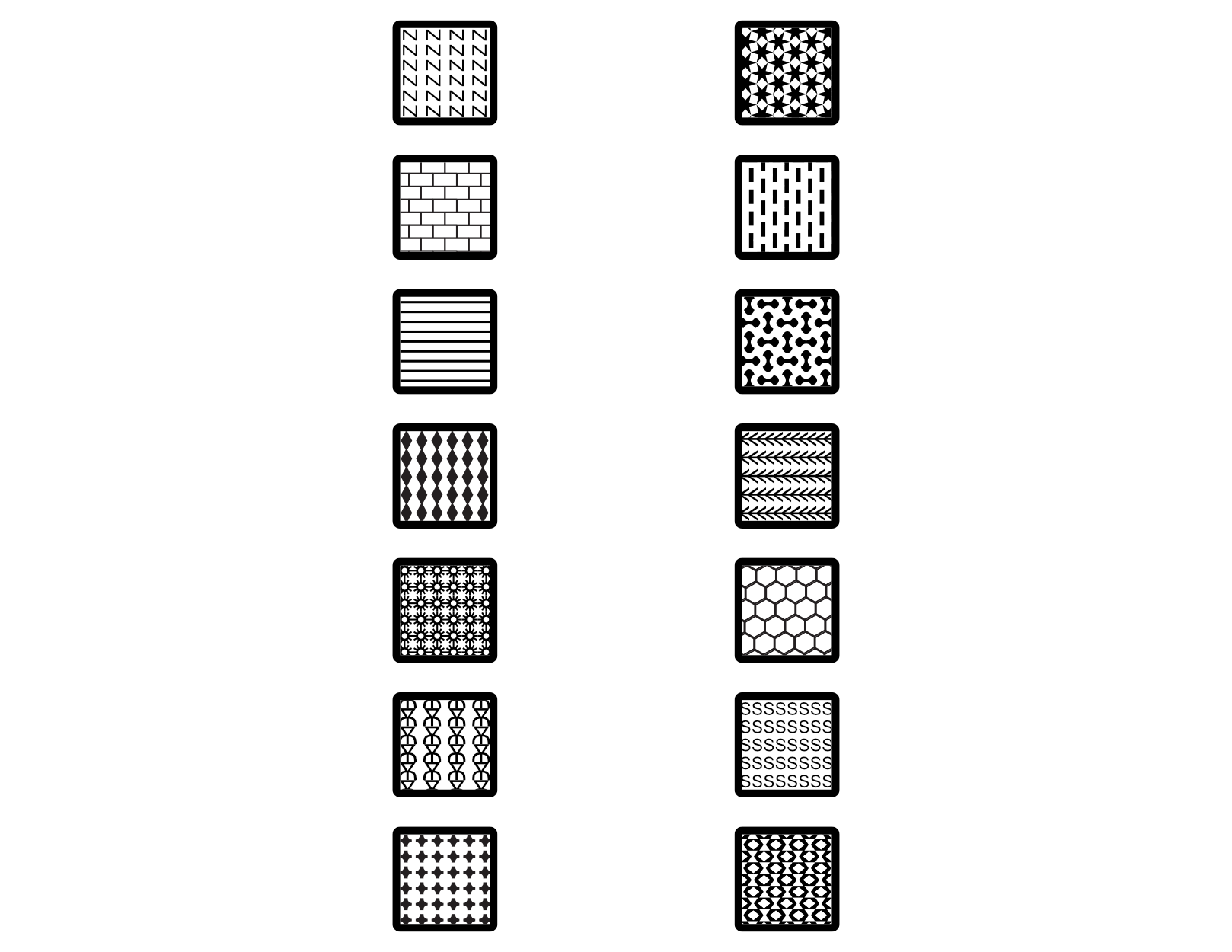

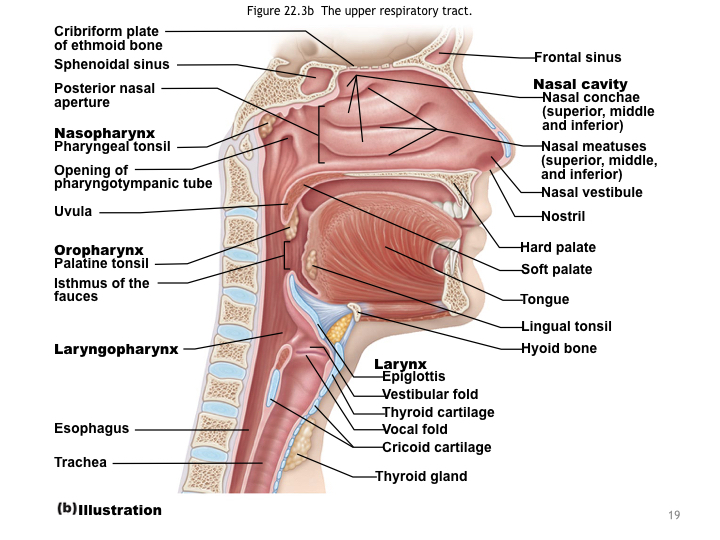

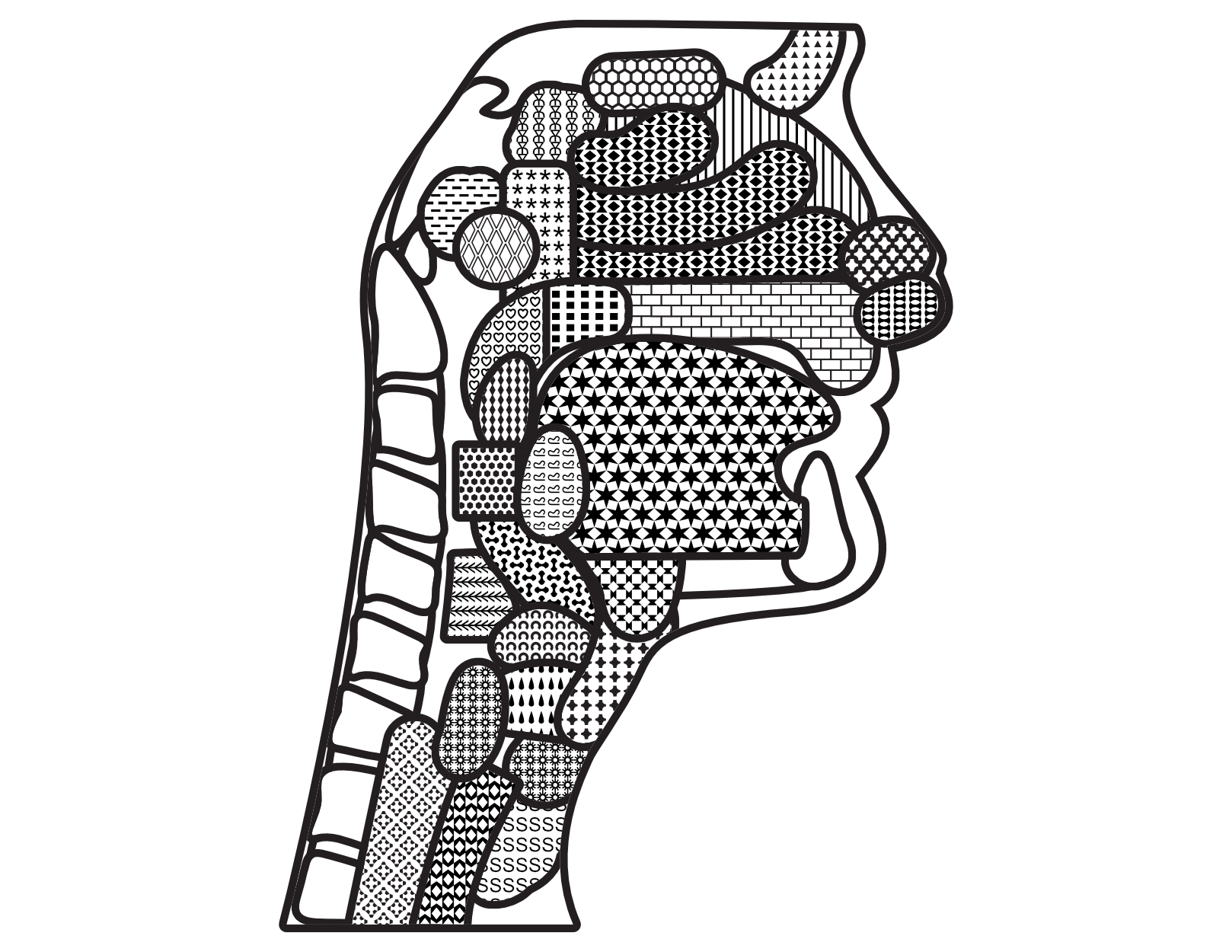

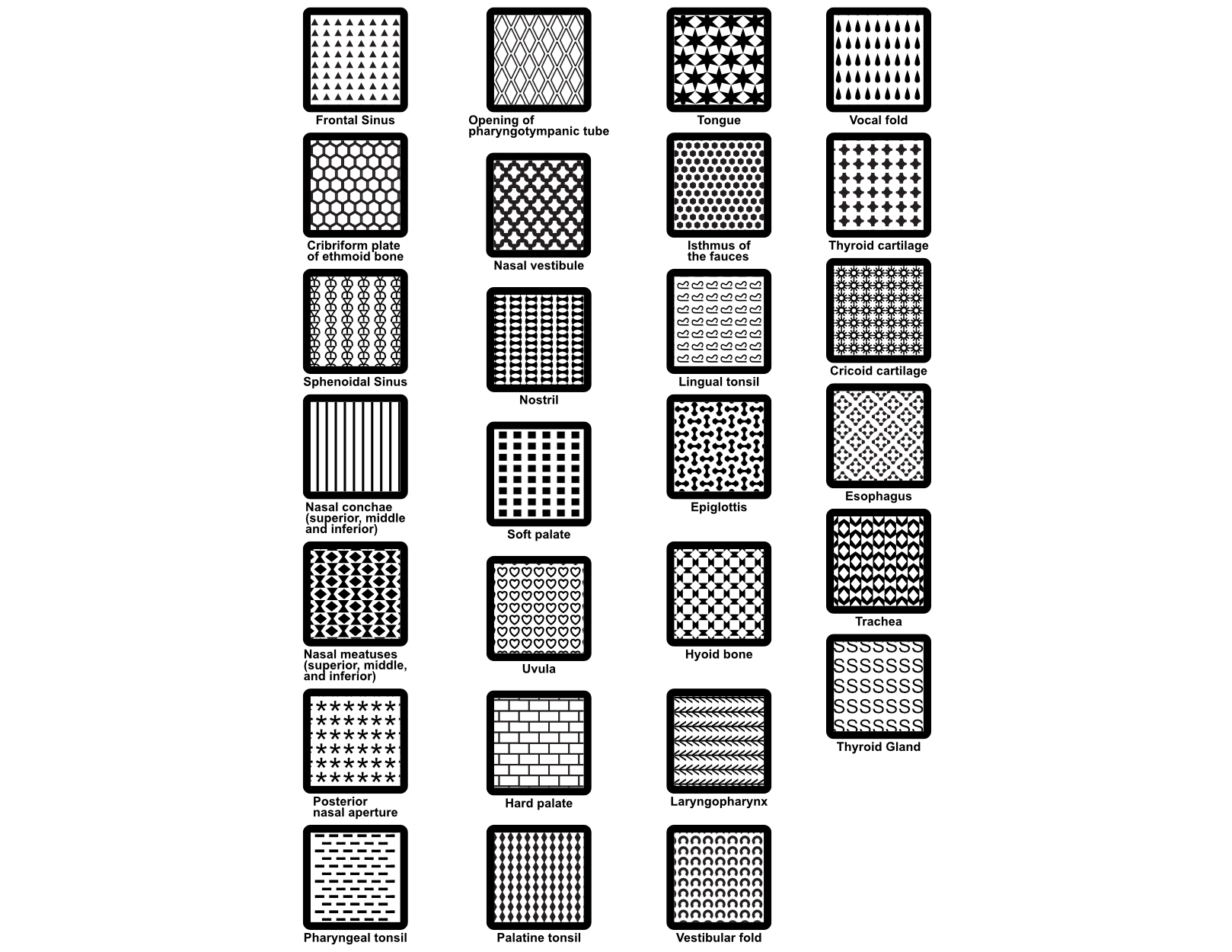

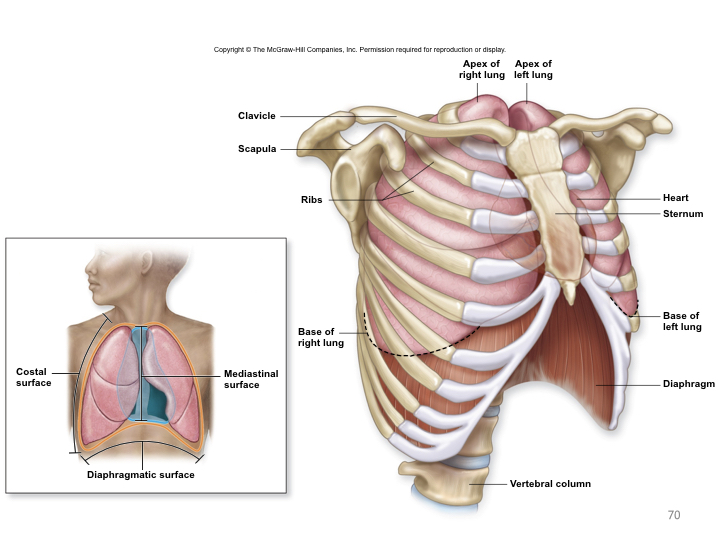

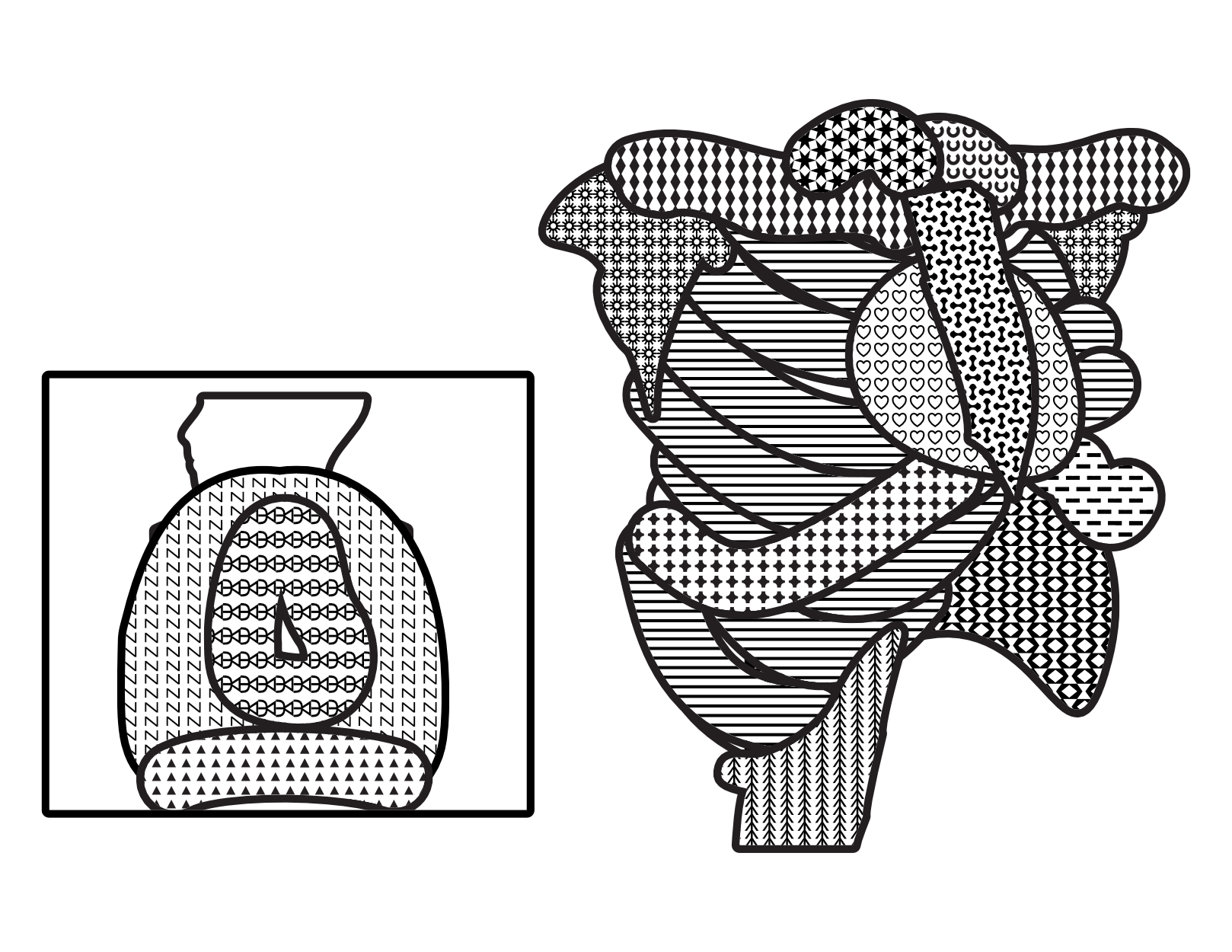

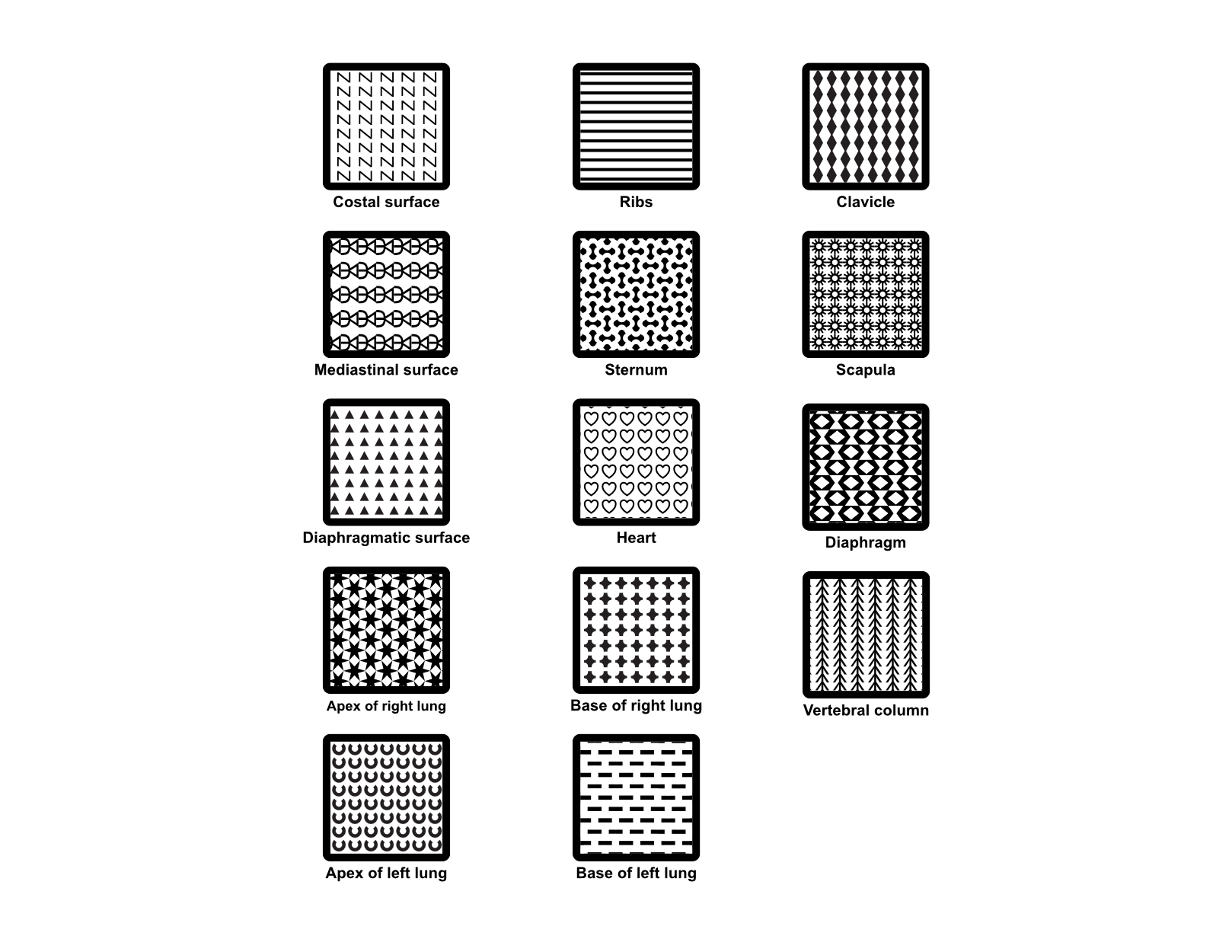

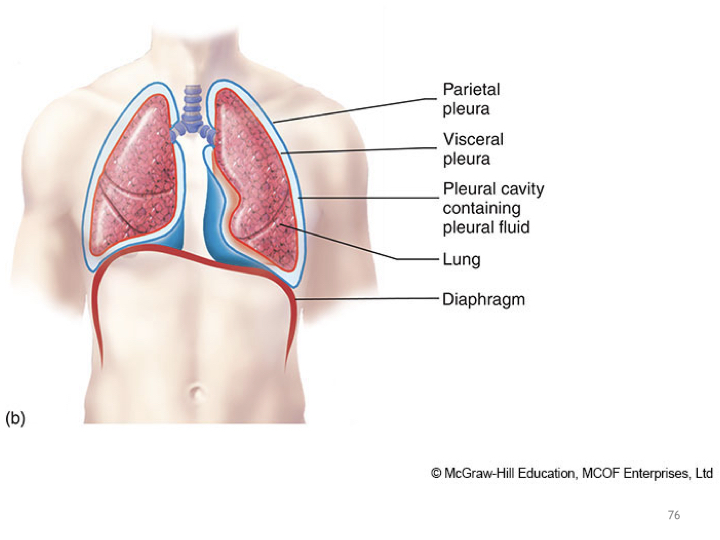

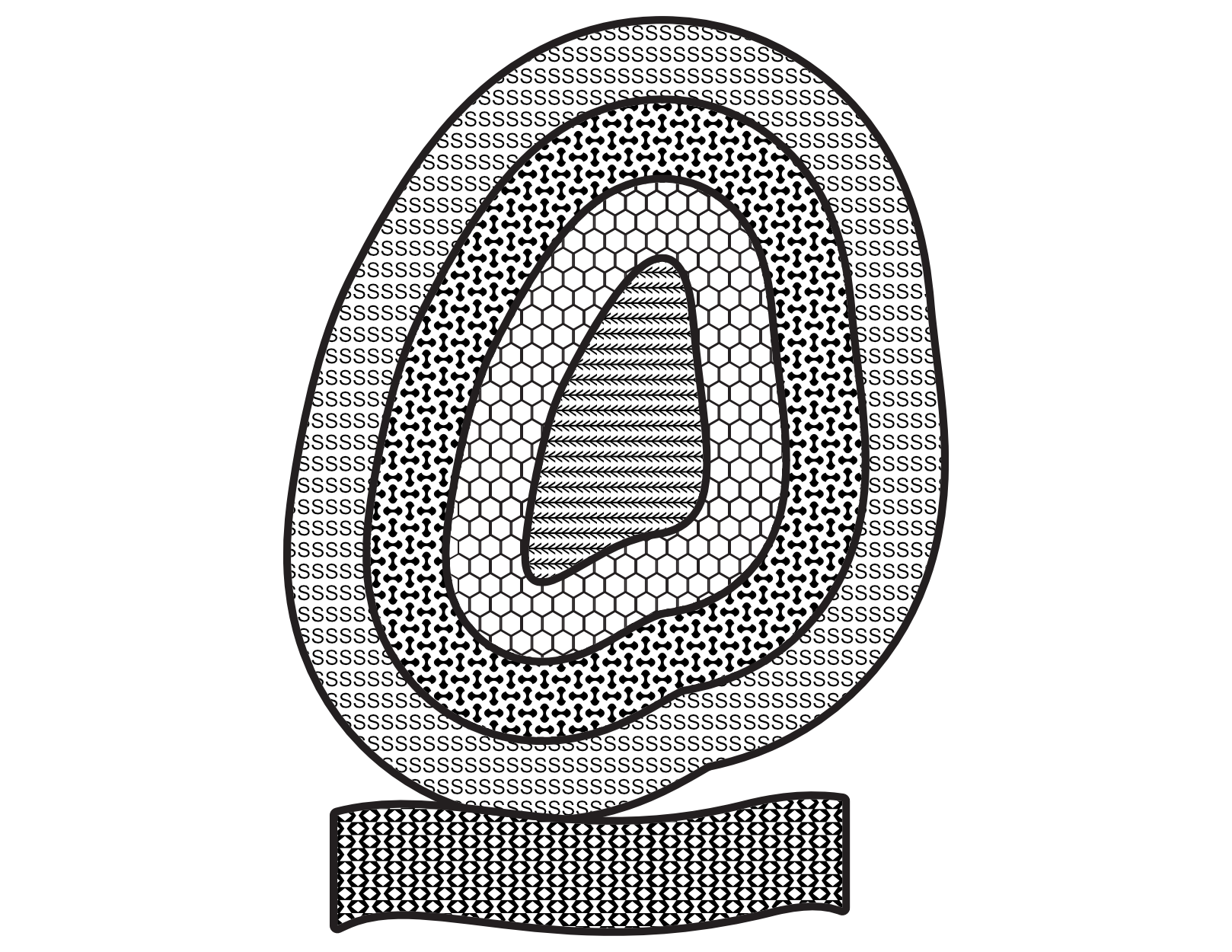

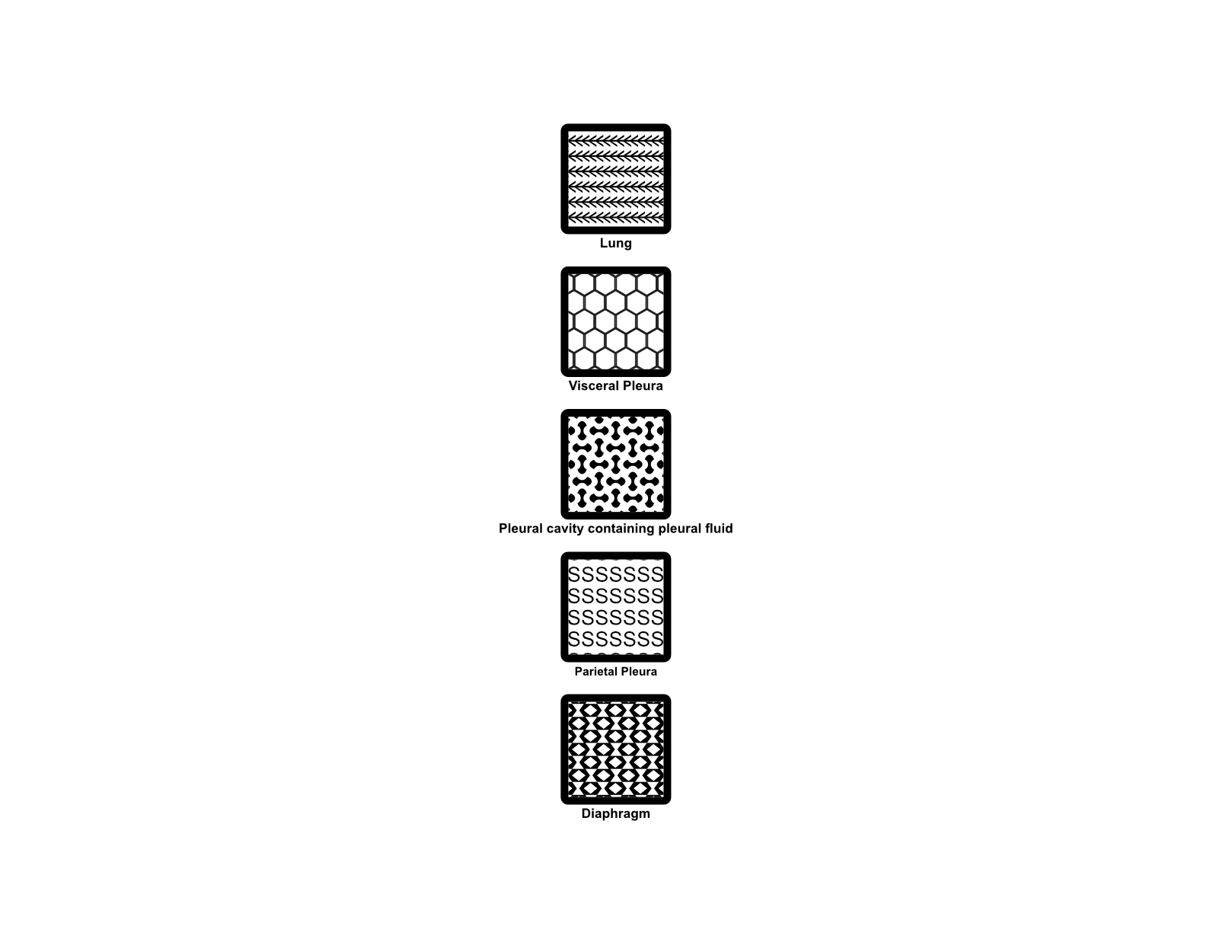

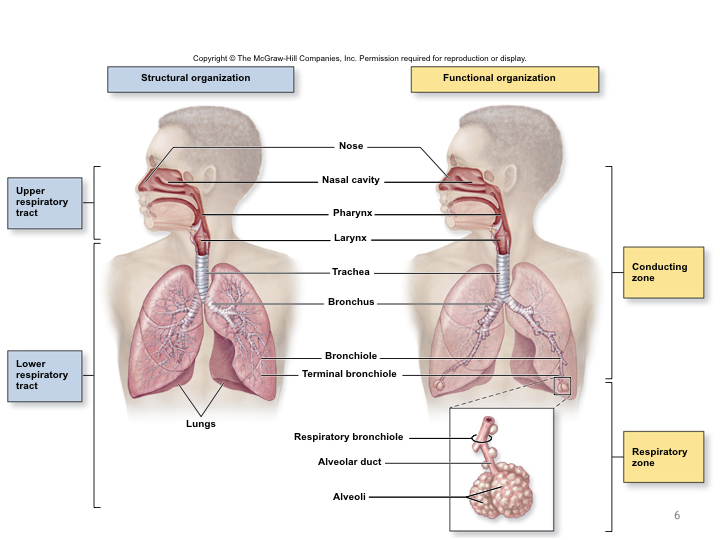

Respiratory System

I did some contract work at MSU Denver creating Tactile Graphics. My employer would send me PowerPoints with images. I simplified the images, creating different patterns for different labels. The patterns are printed as raised graphics on swell paper. The blind students can feel them and understand the illustration using a key.

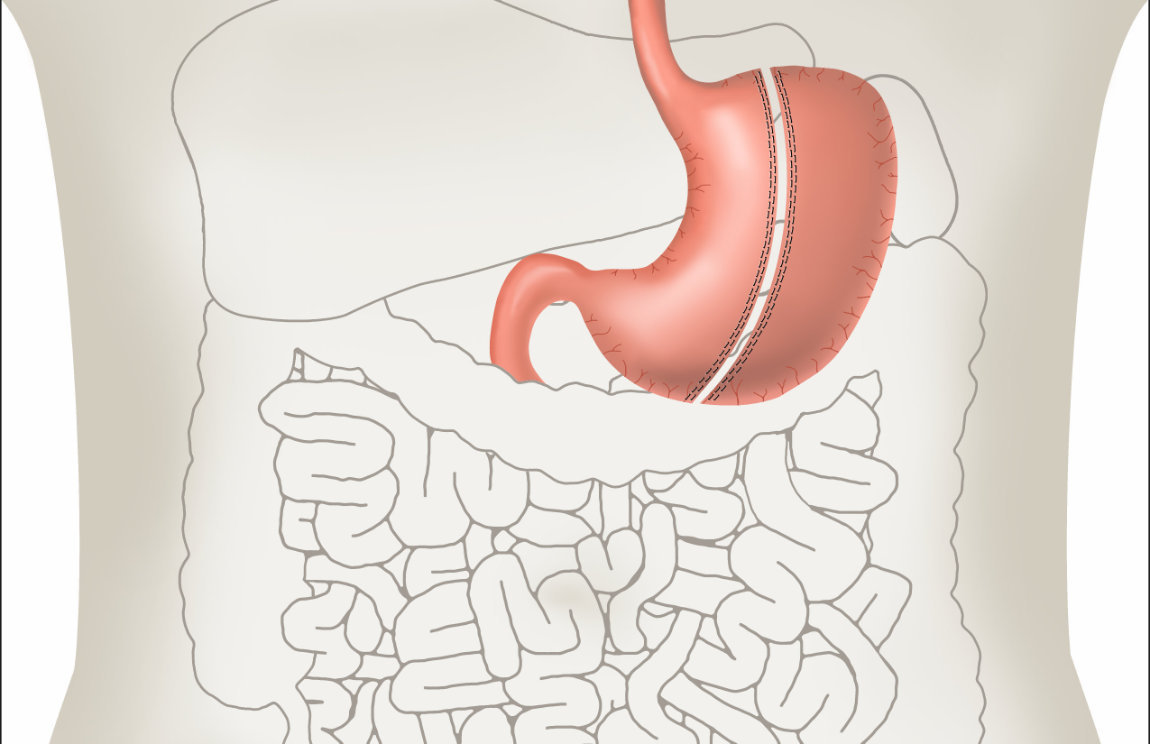

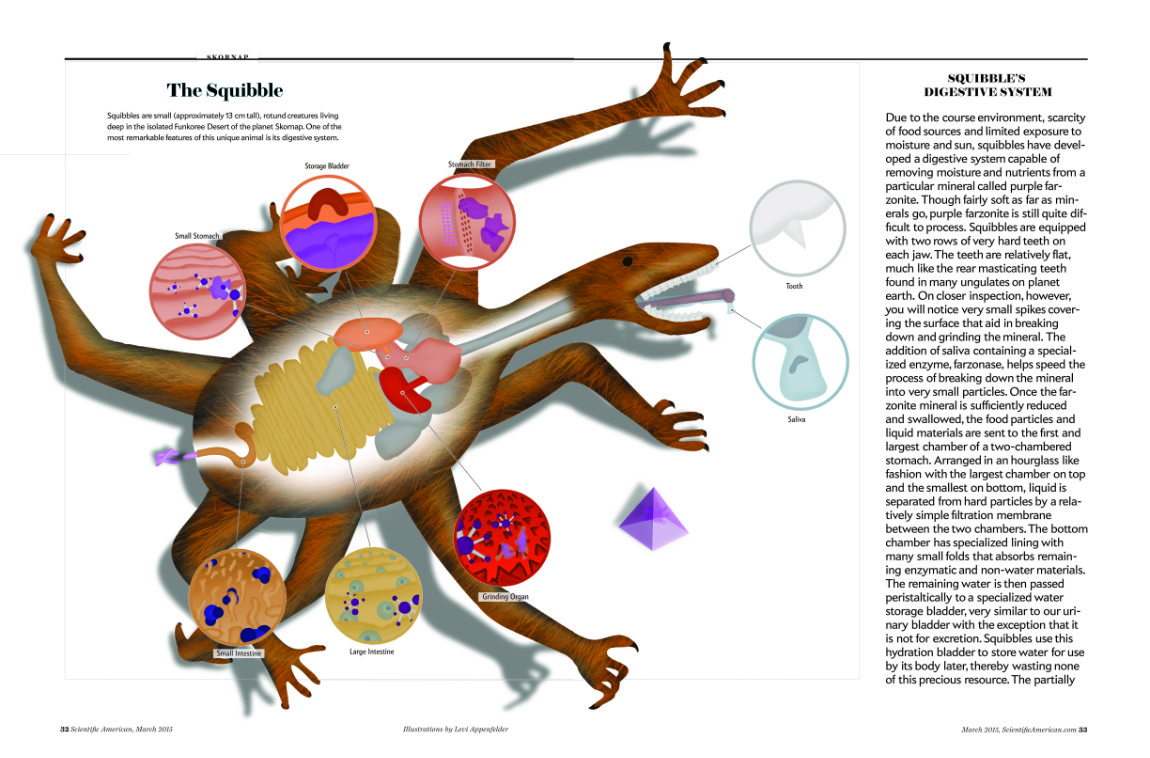

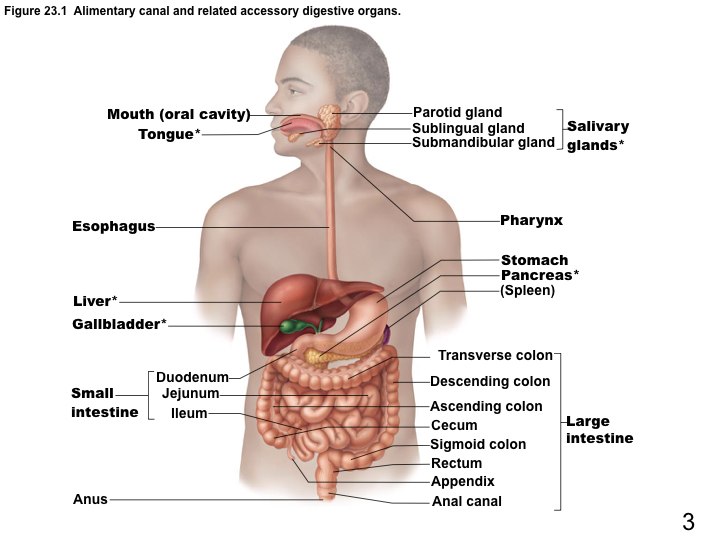

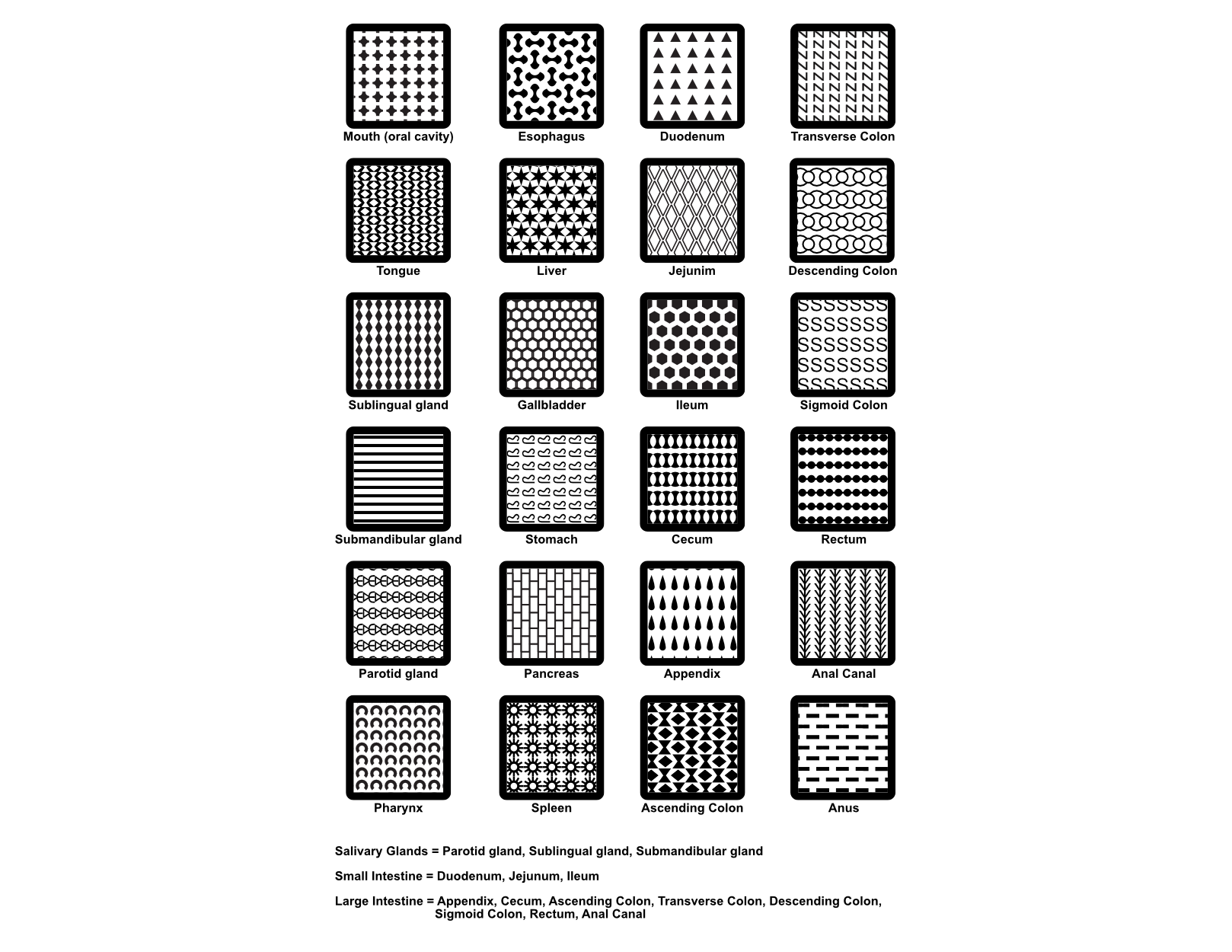

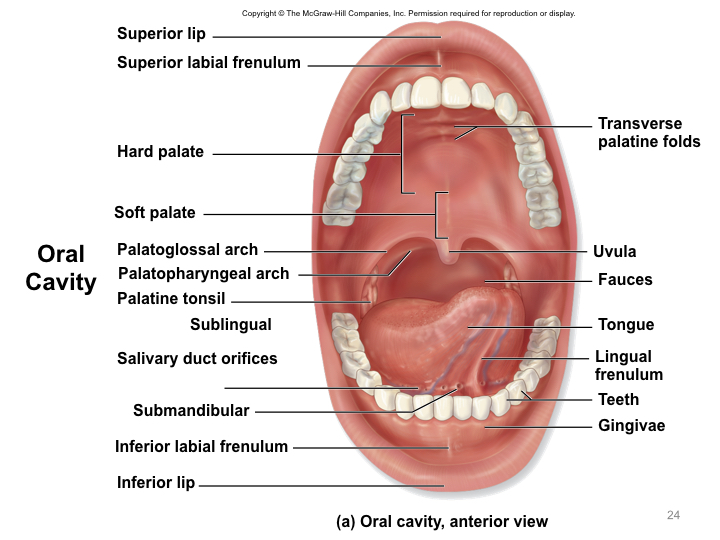

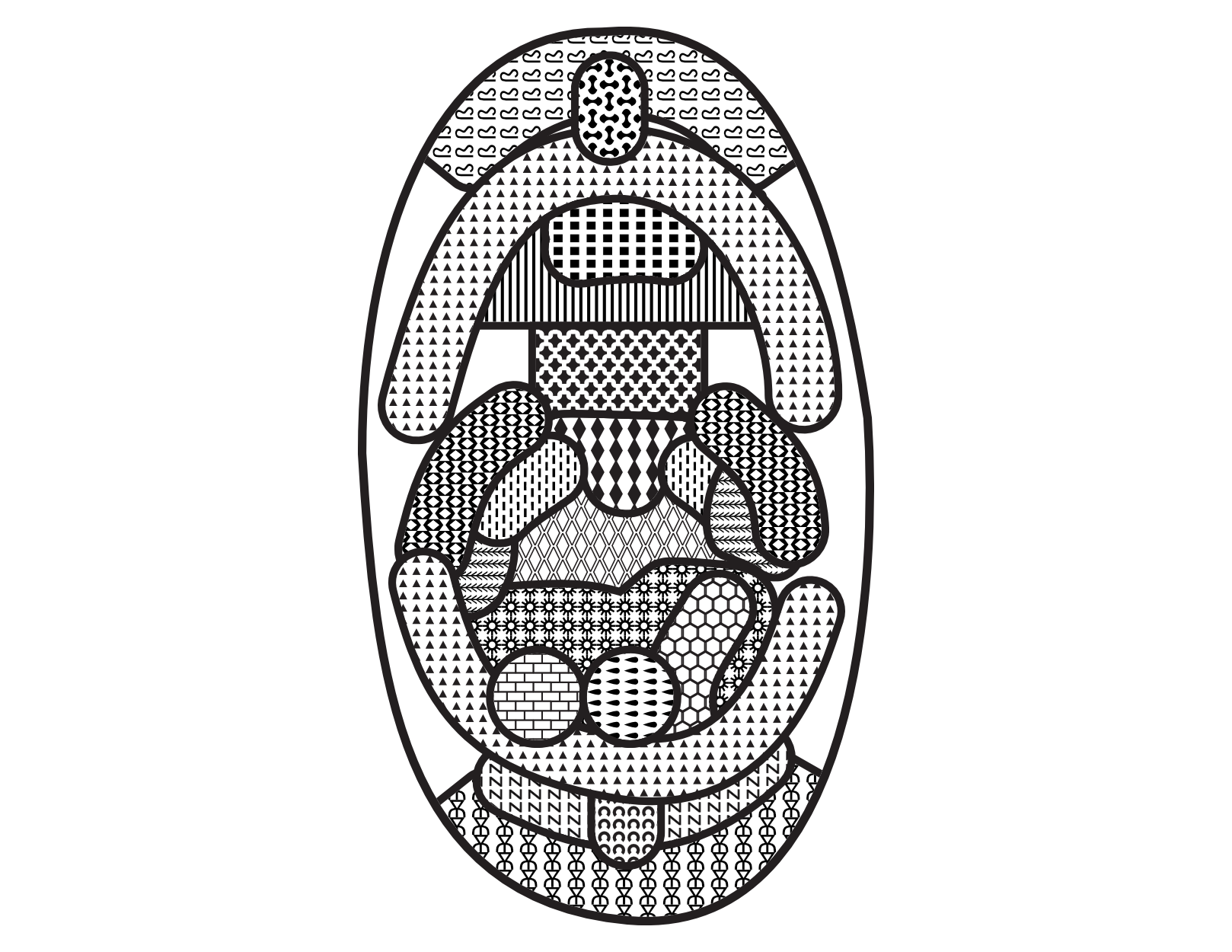

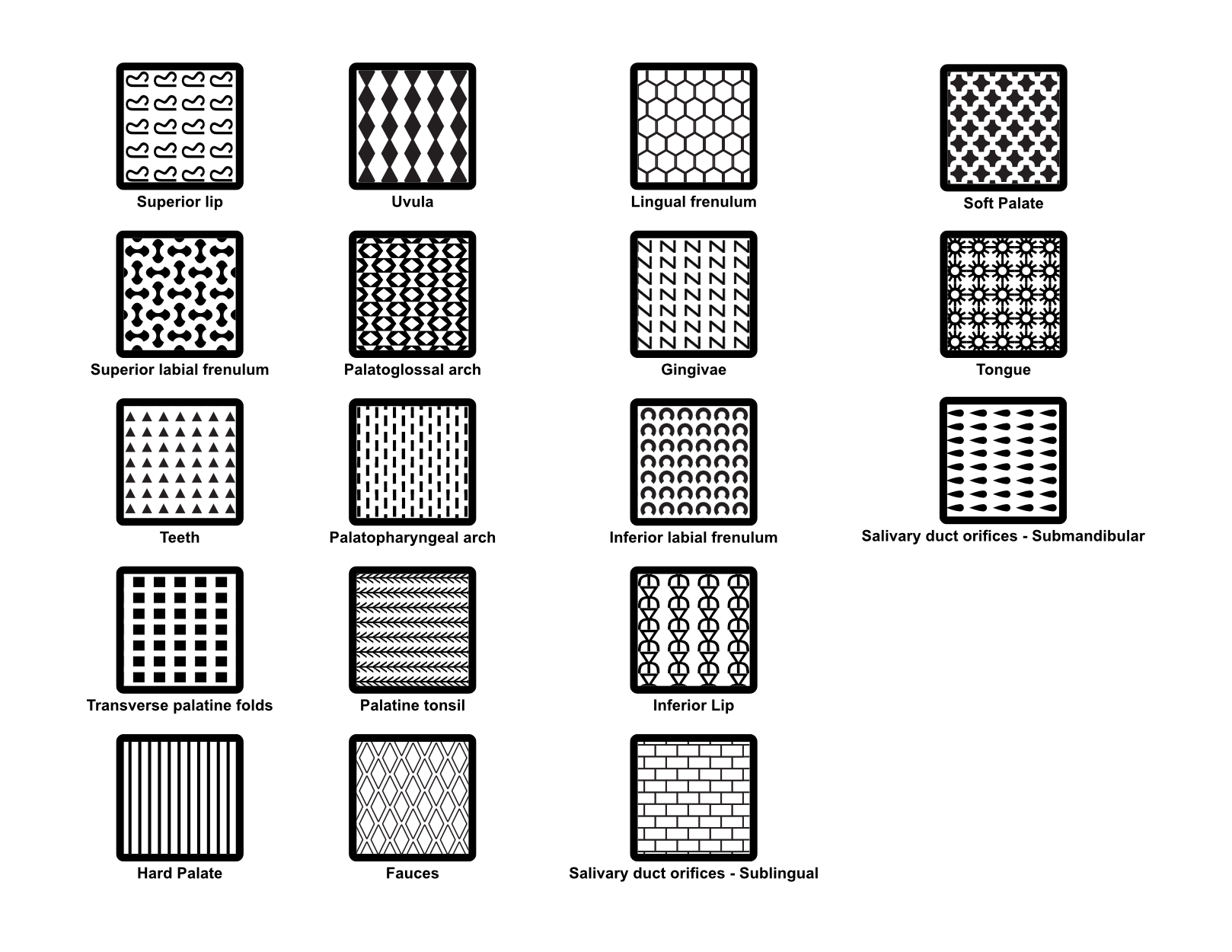

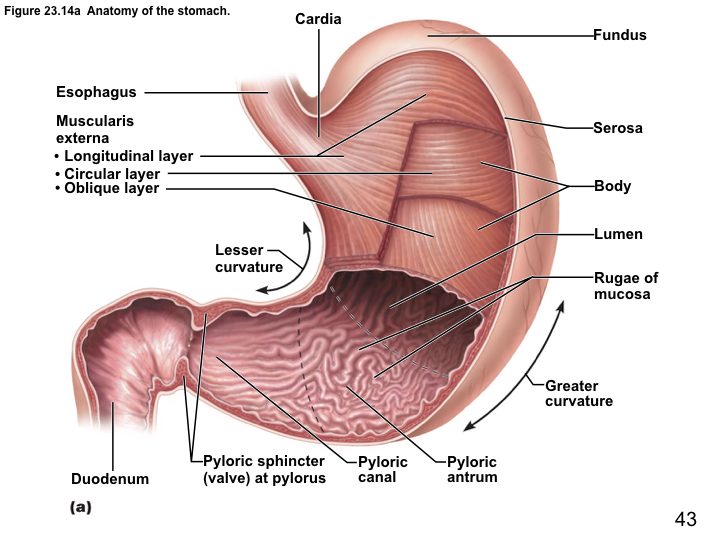

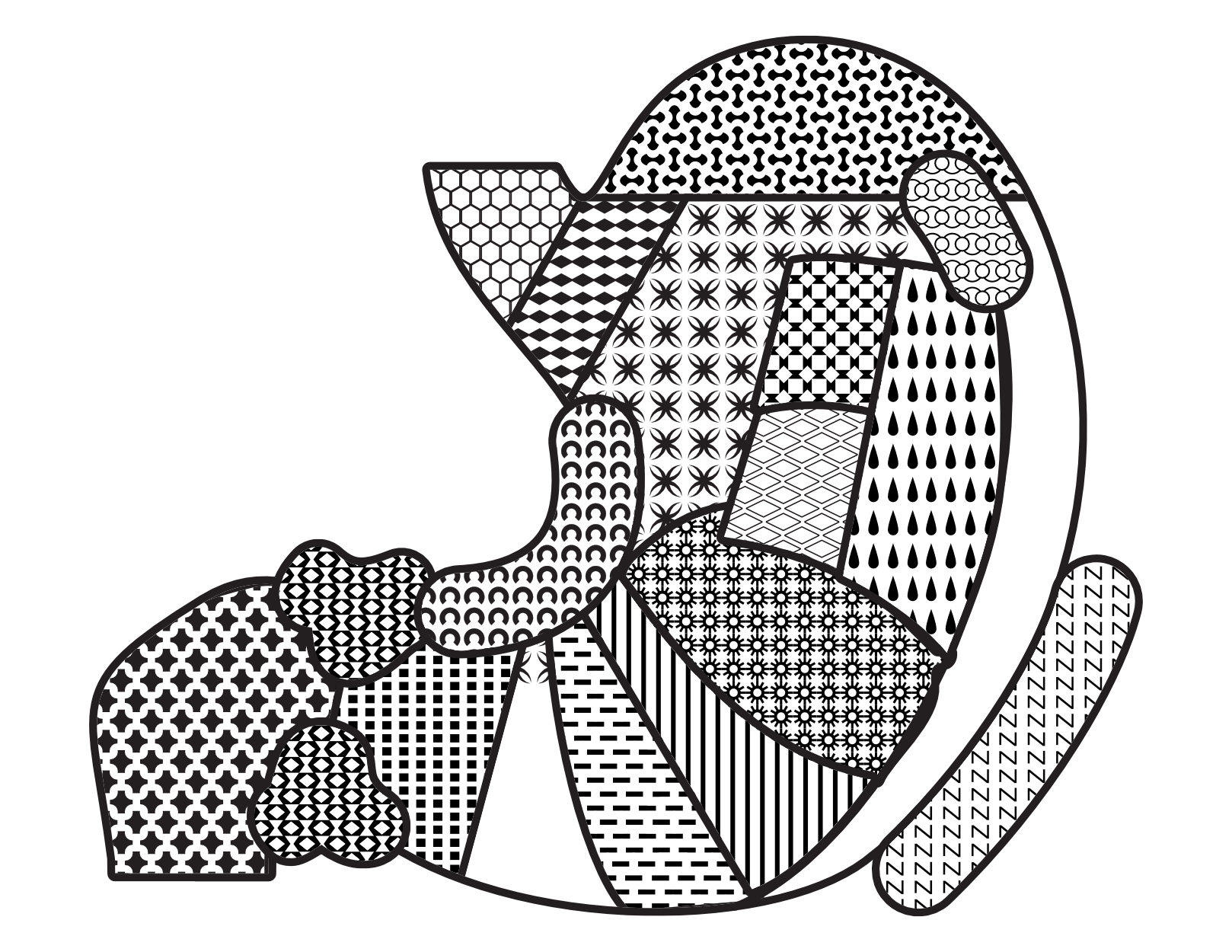

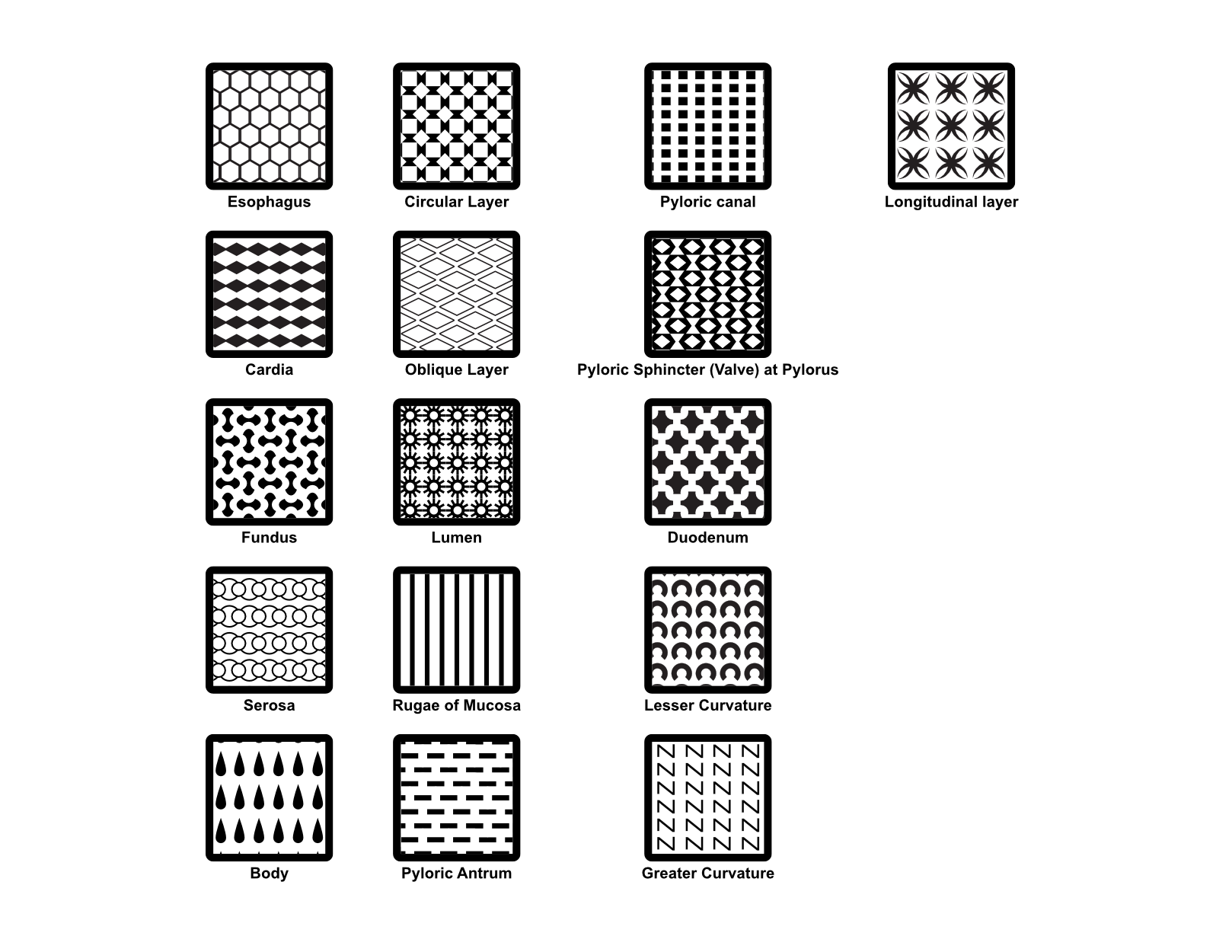

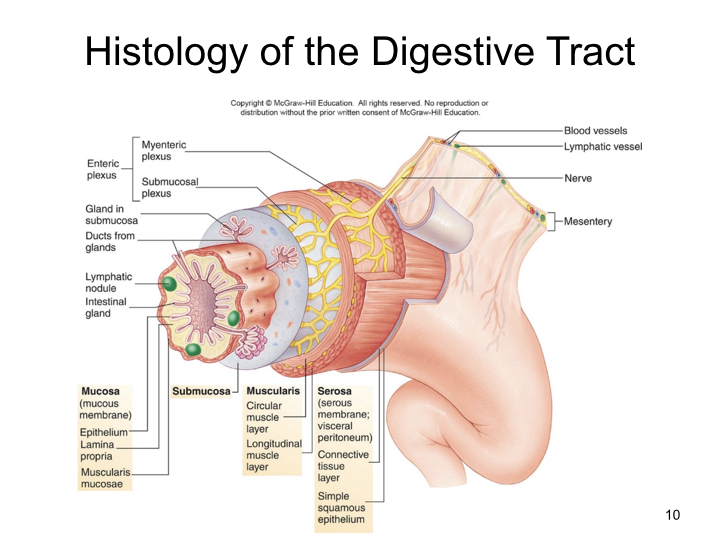

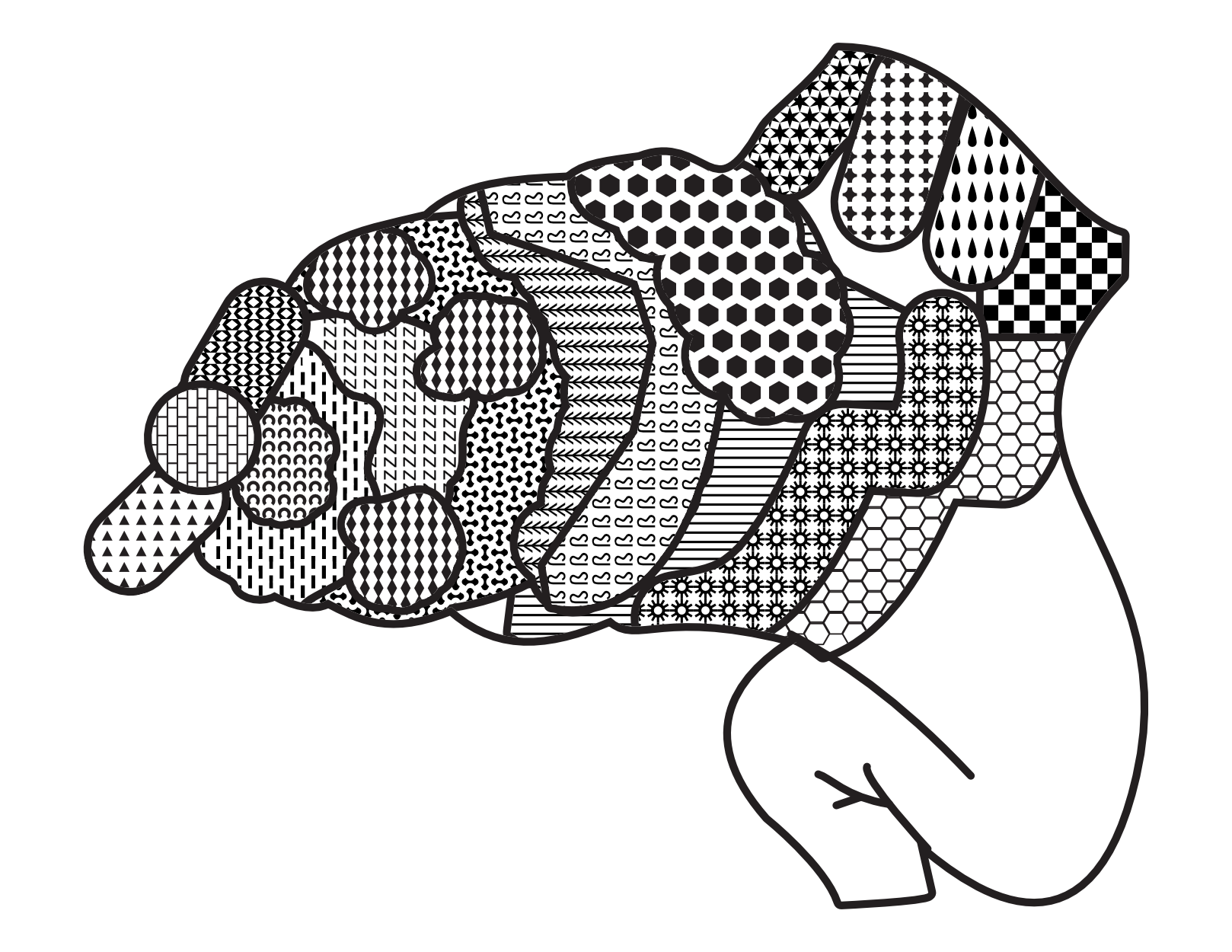

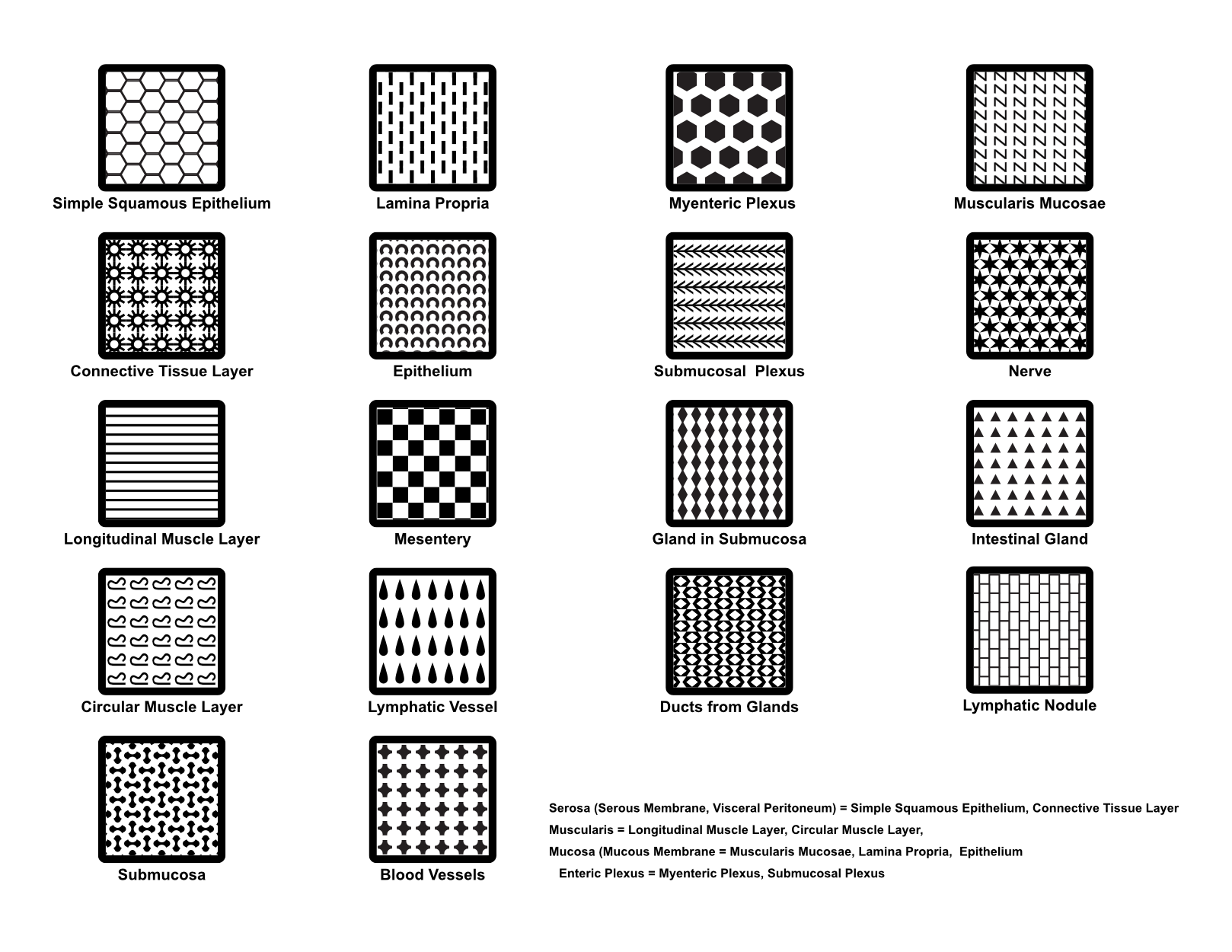

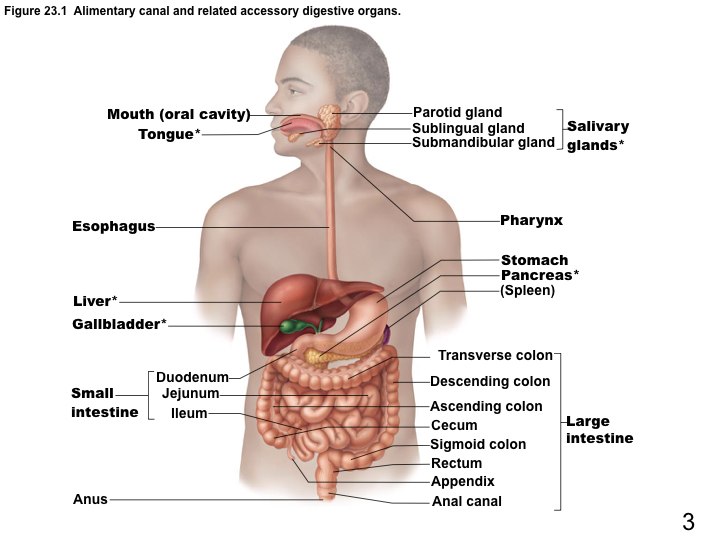

Digestive System

I did some contract work at MSU Denver creating Tactile Graphics. My employer would send me PowerPoints with images. I simplified the images, creating different patterns for different labels. The patterns are printed as raised graphics on swell paper. The blind students can feel them and understand the illustration using a key.

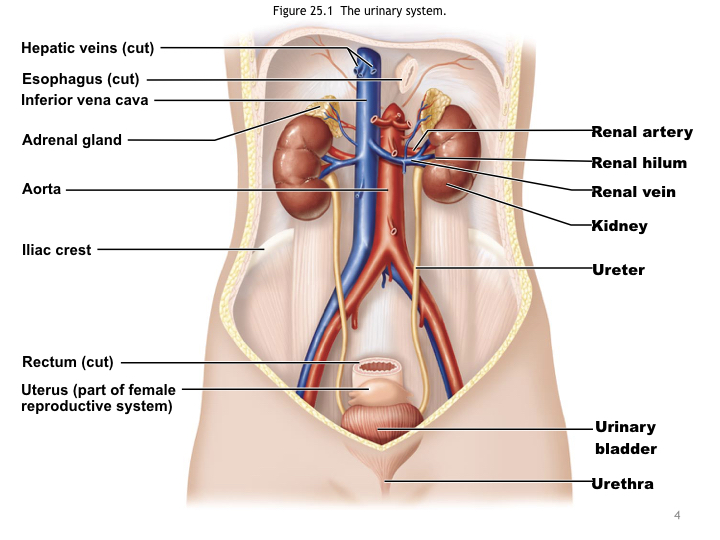

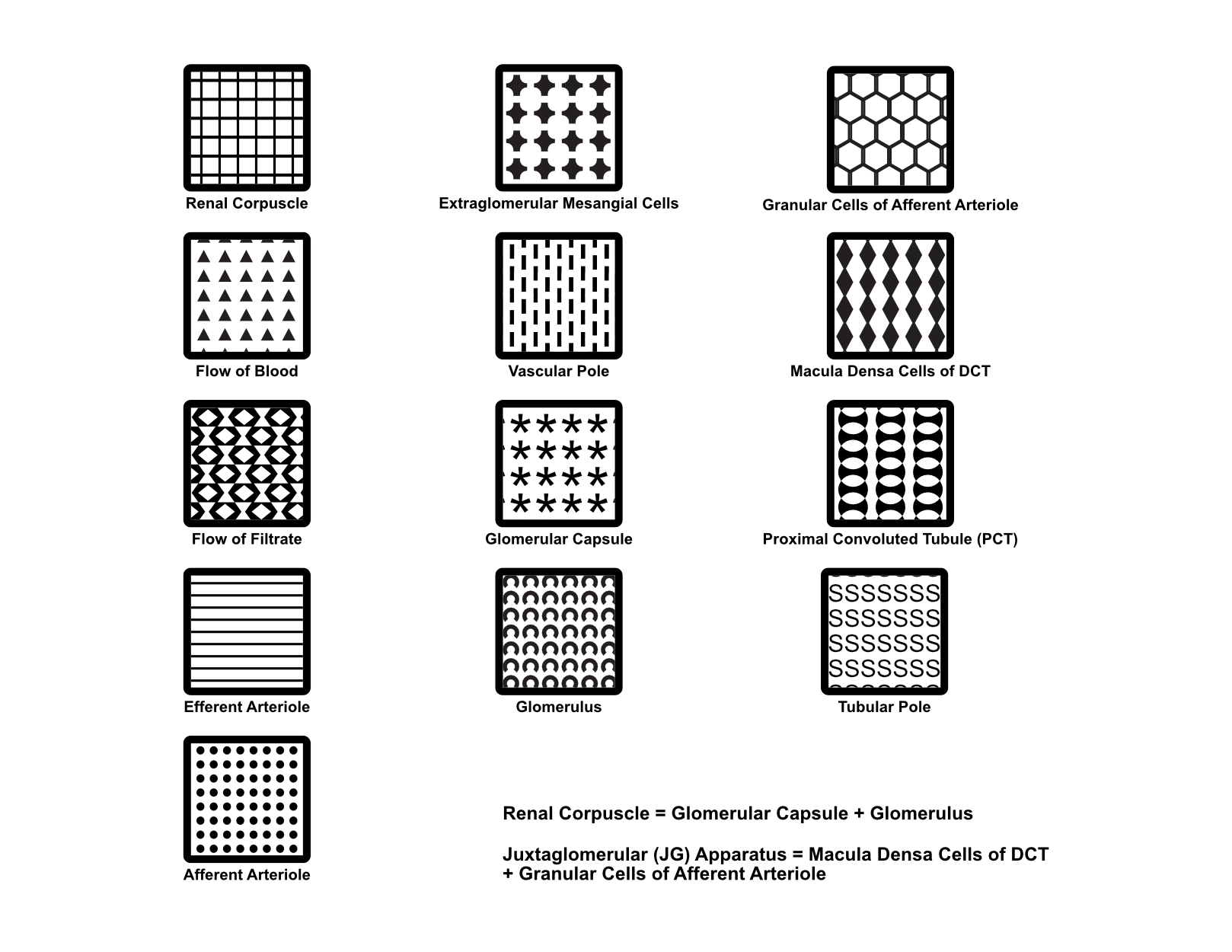

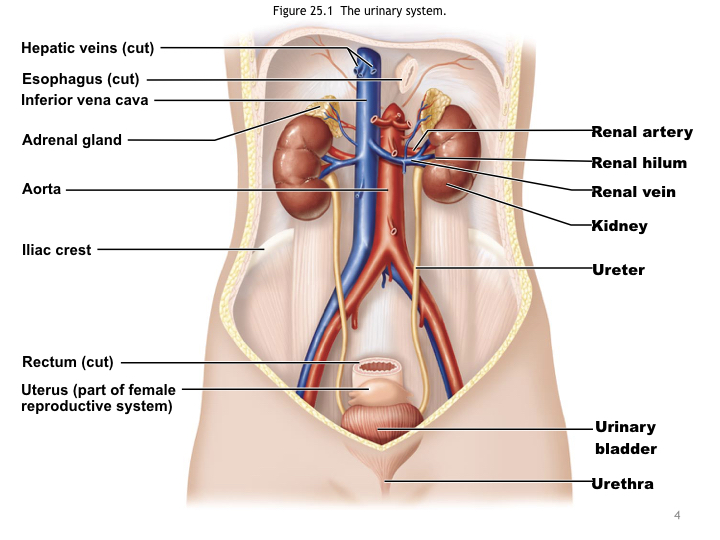

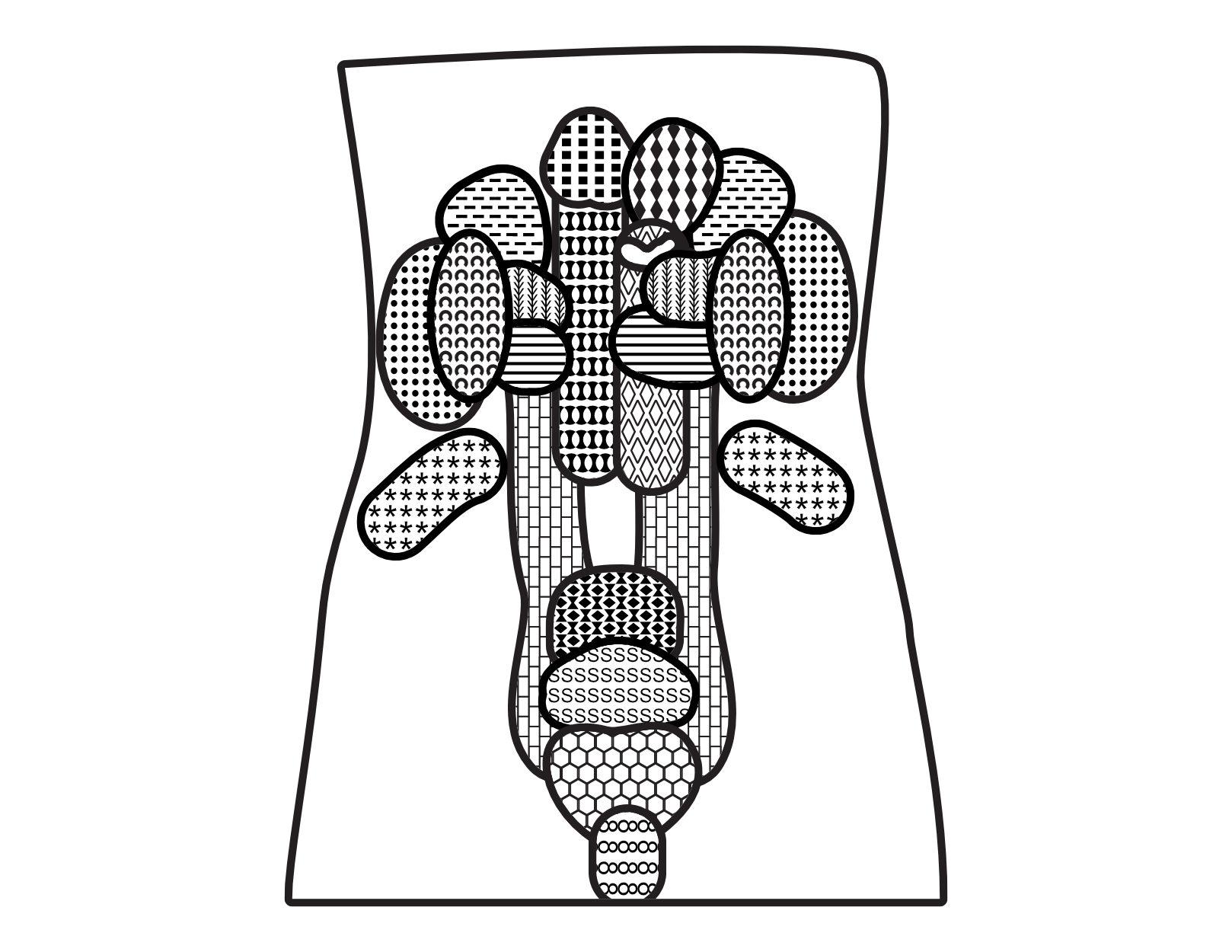

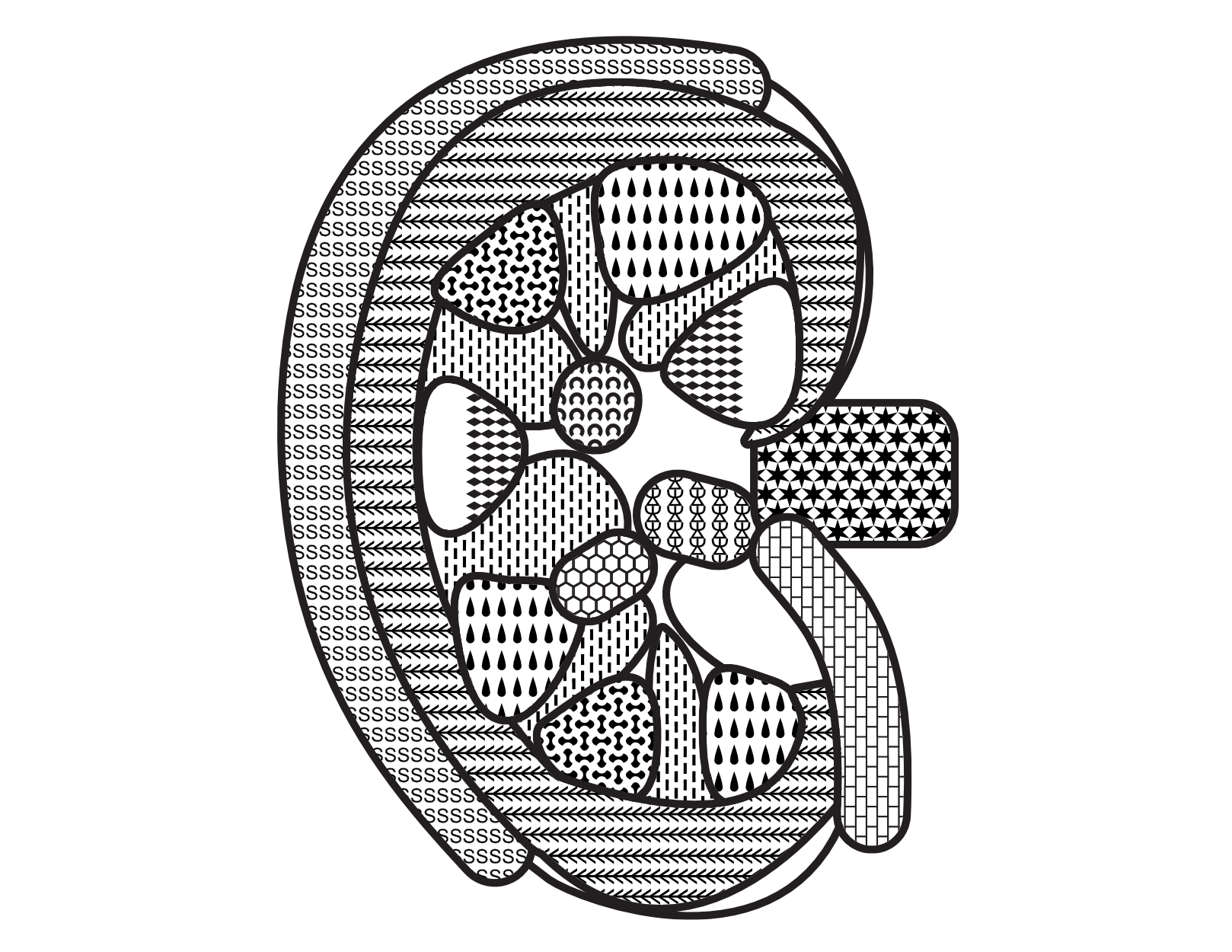

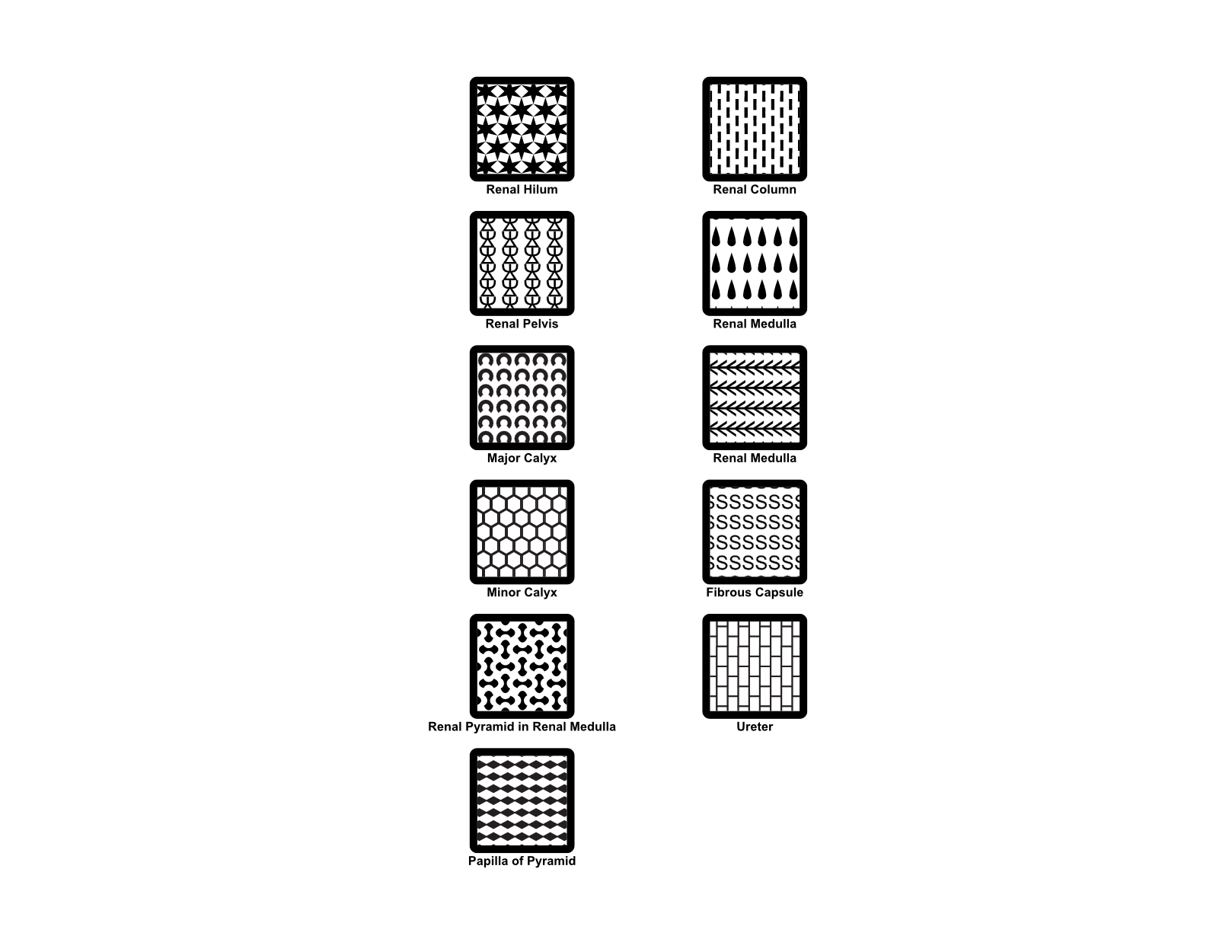

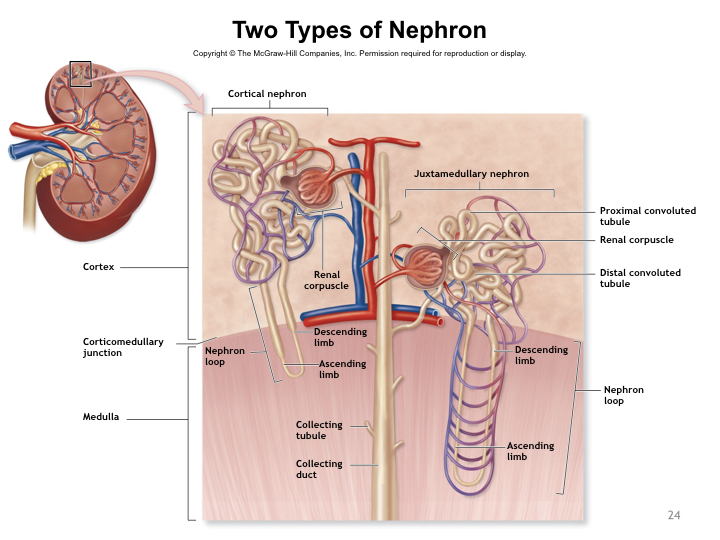

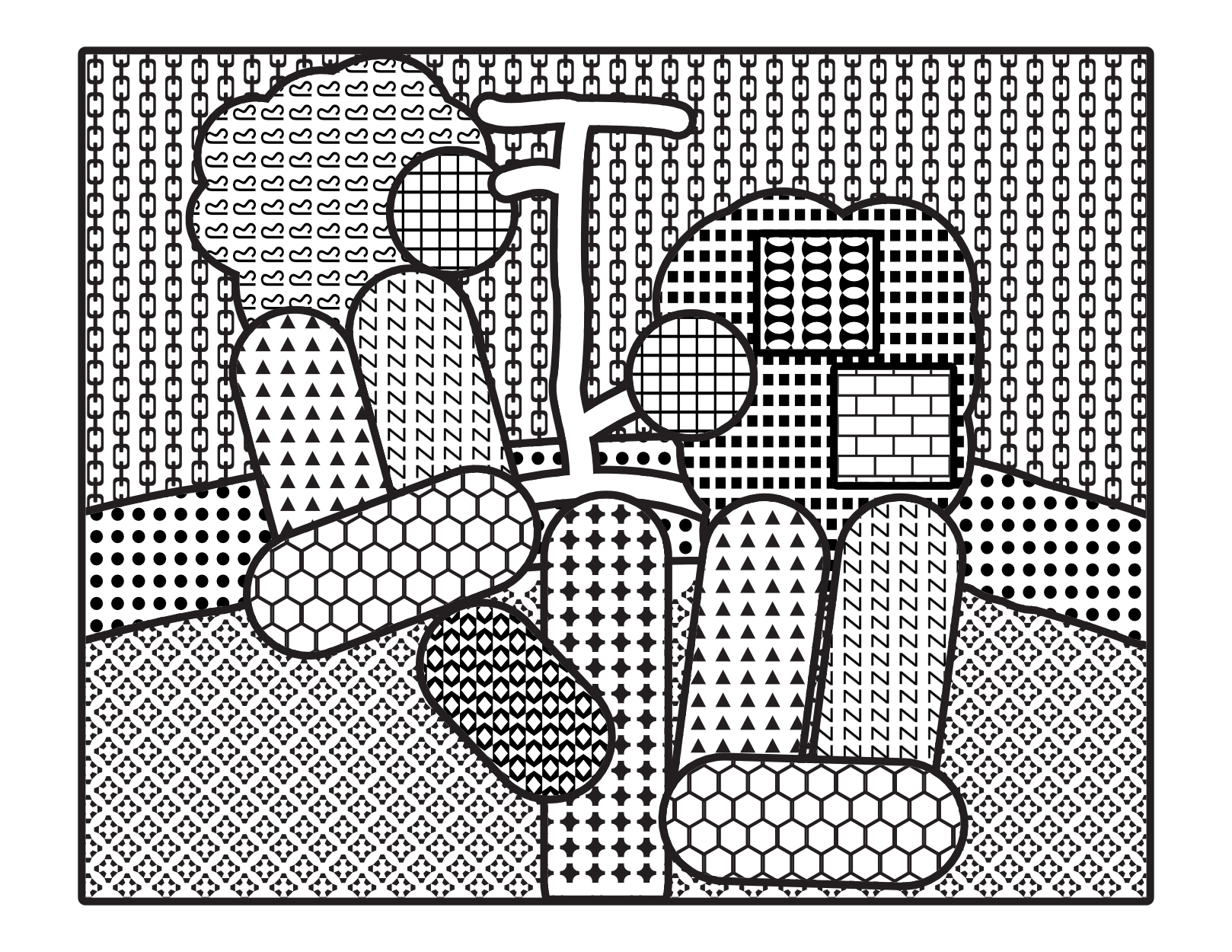

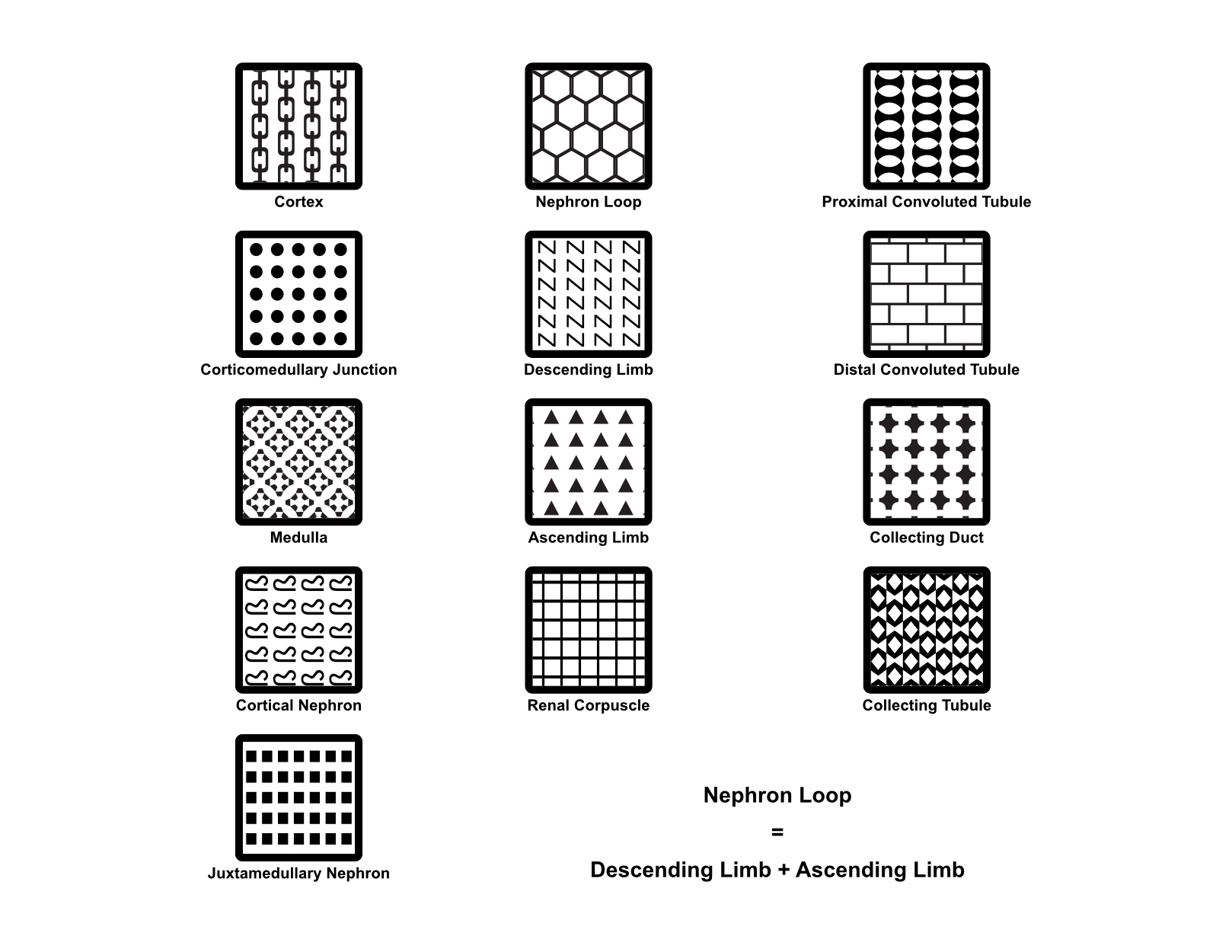

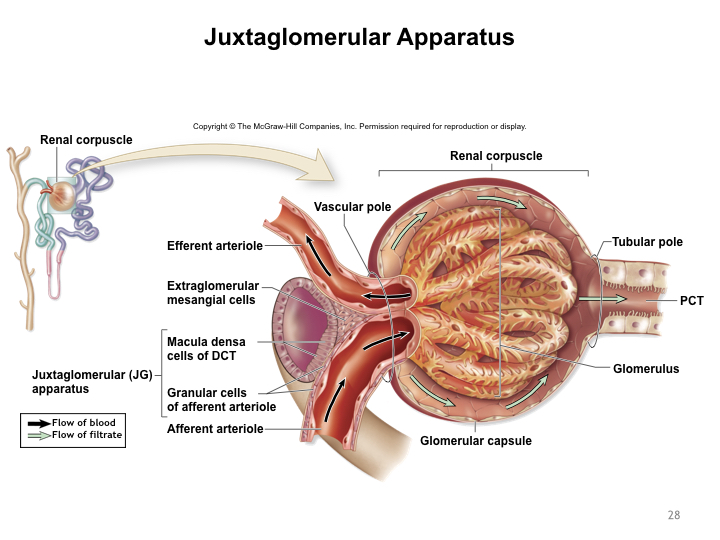

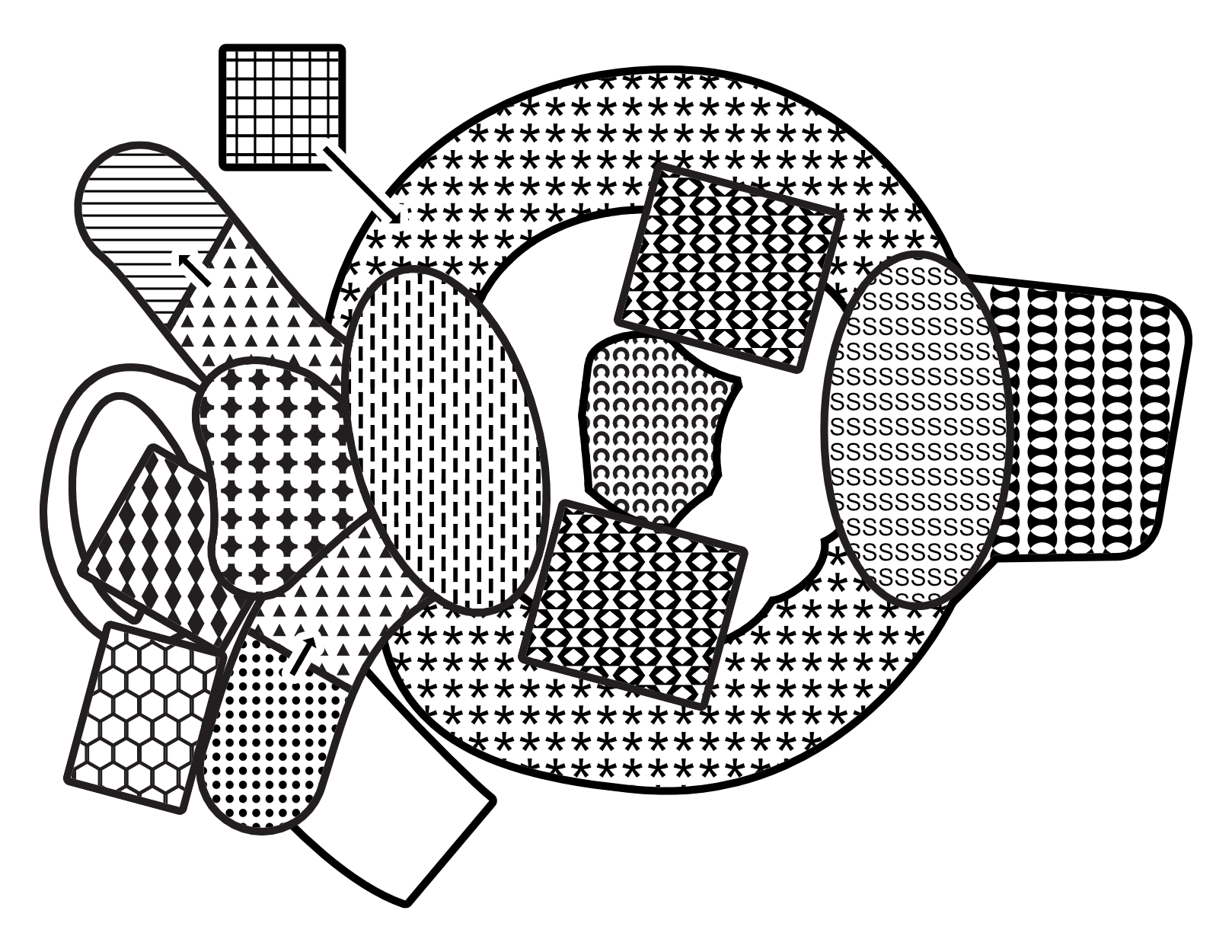

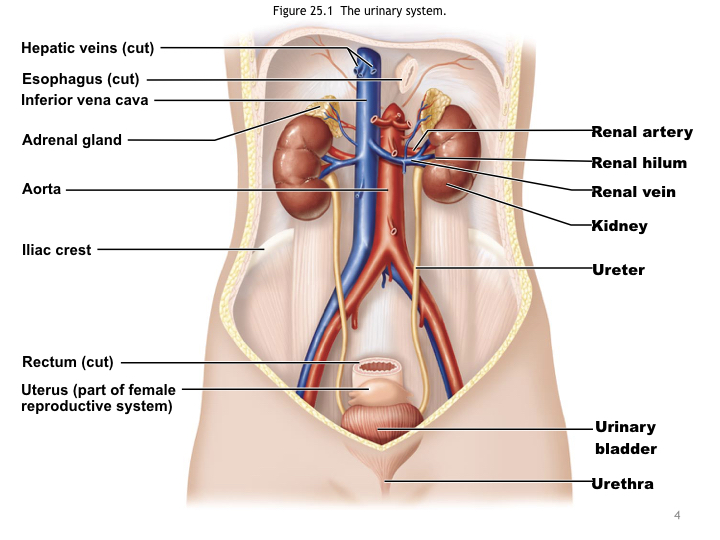

Urinary System

I did some contract work at MSU Denver creating Tactile Graphics. My employer would send me PowerPoints with images. I simplified the images, creating different patterns for different labels. The patterns are printed as raised graphics on swell paper. The blind students can feel them and understand the illustration using a key.

Rocket Science

Design Building

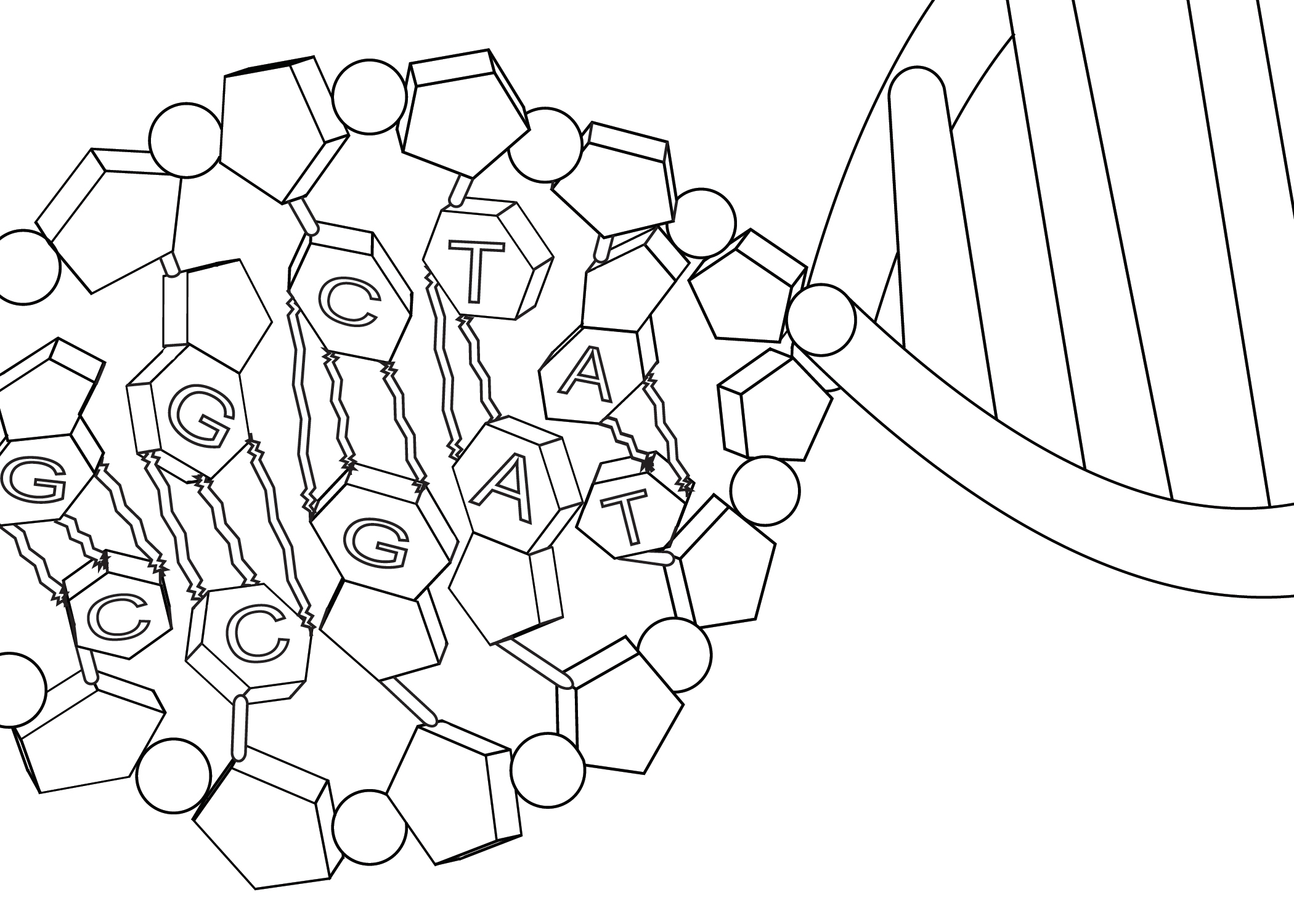

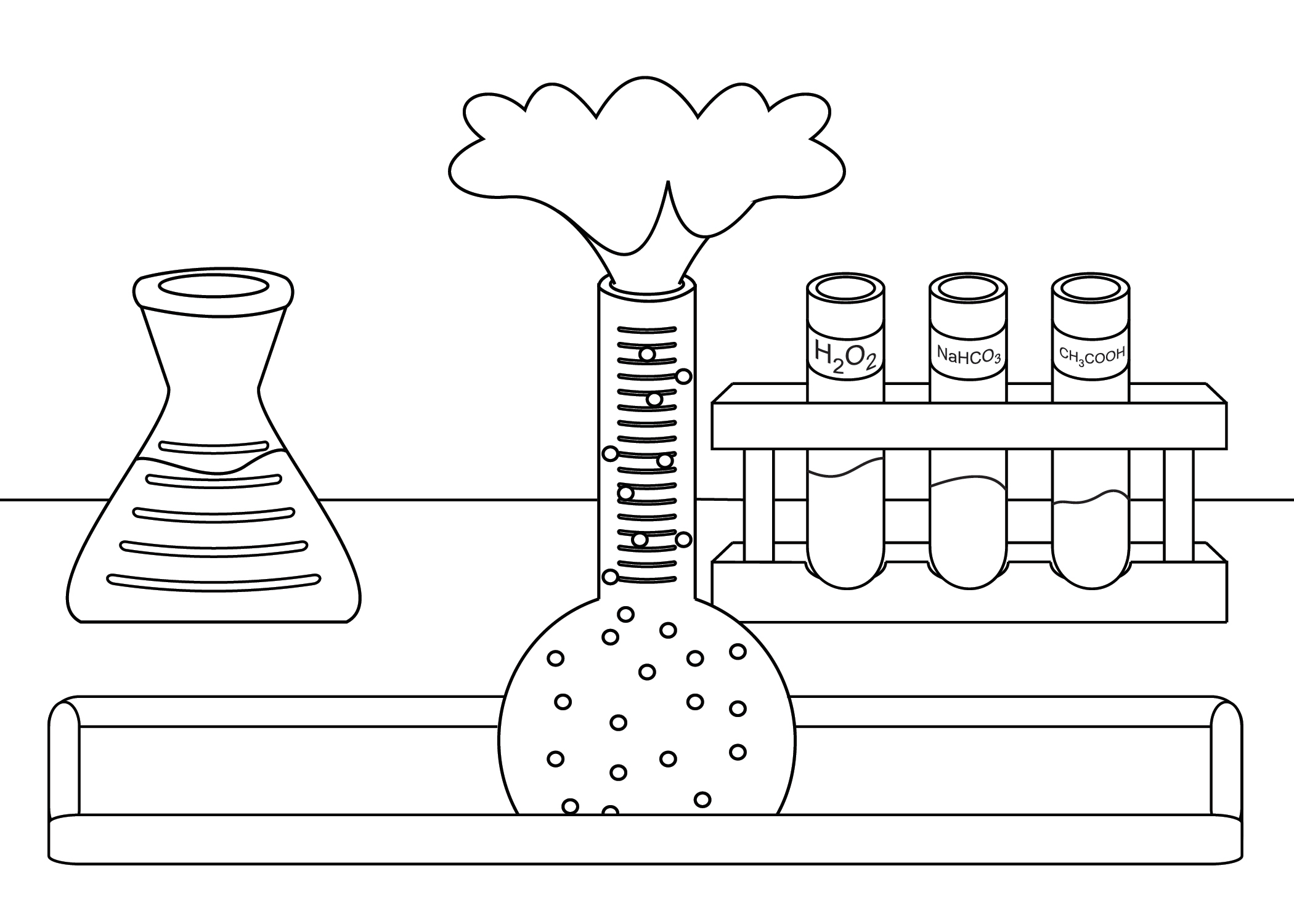

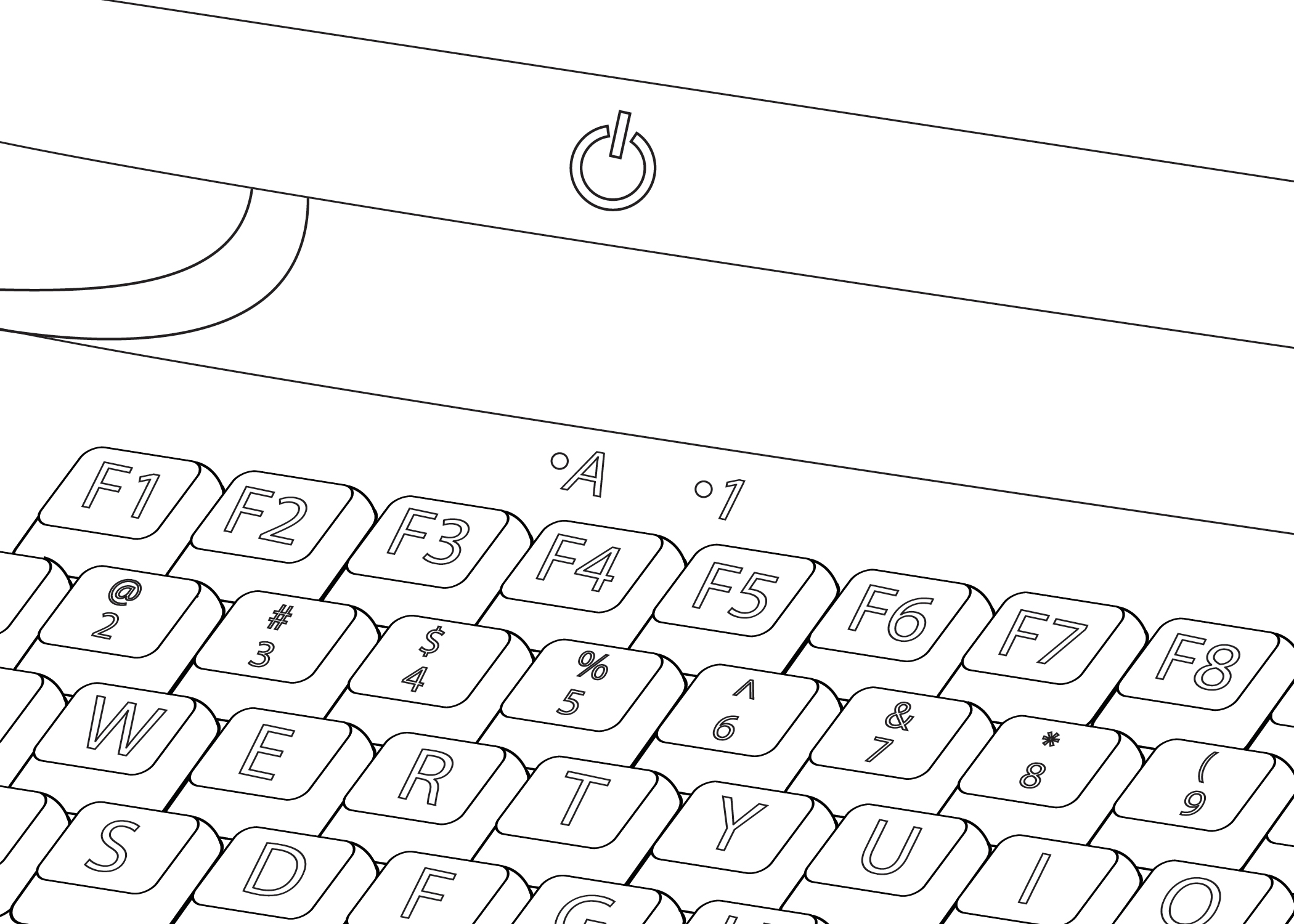

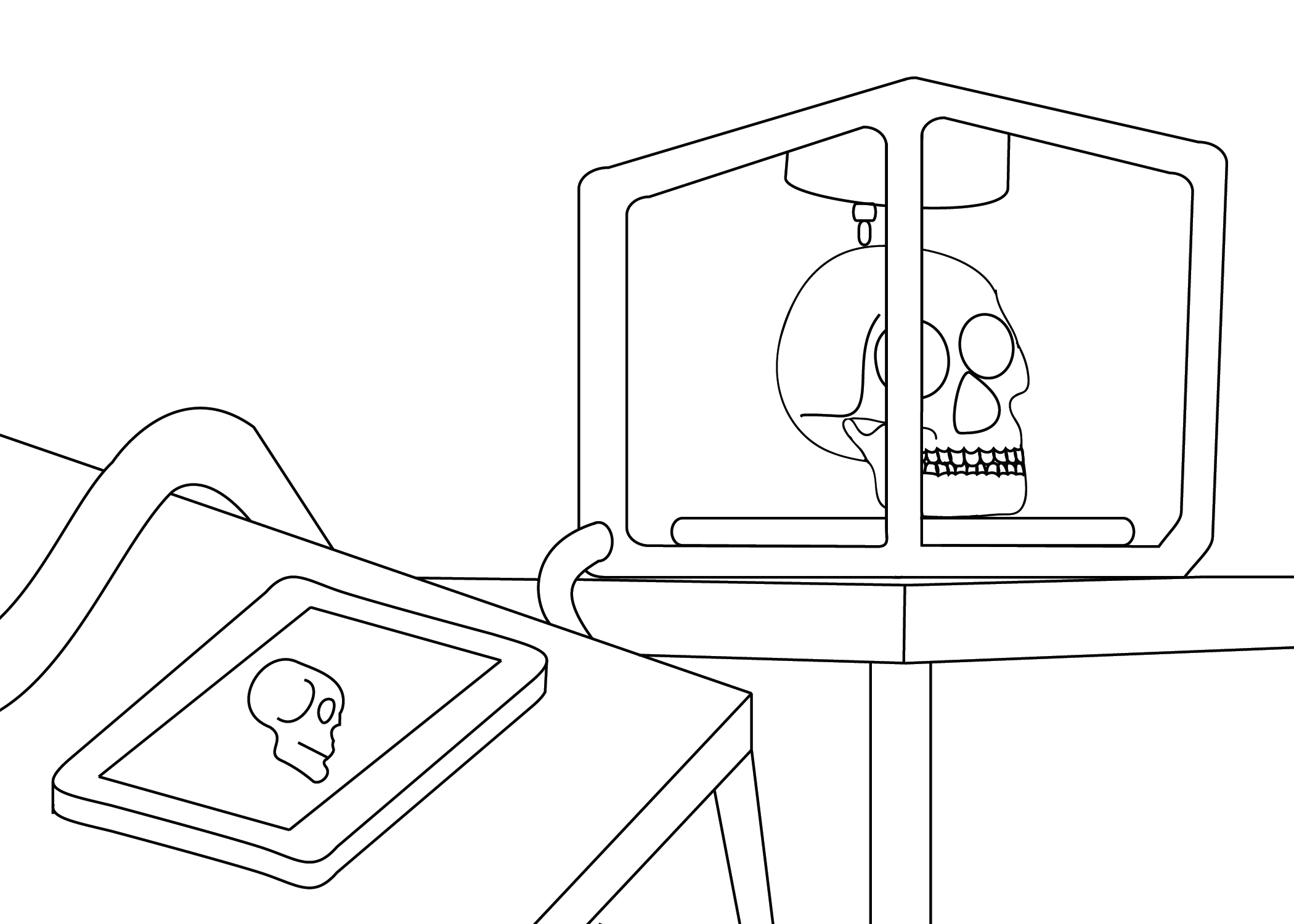

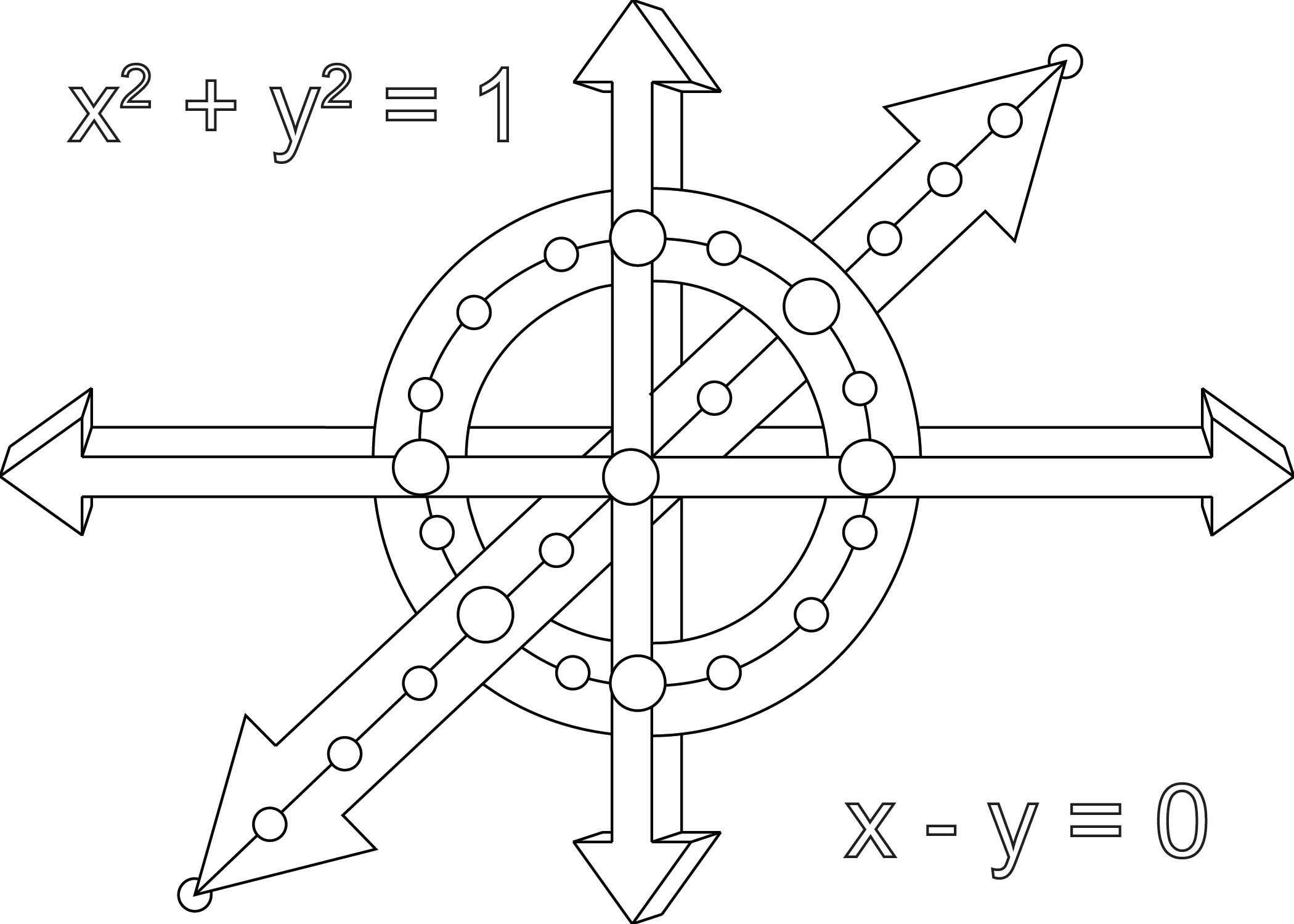

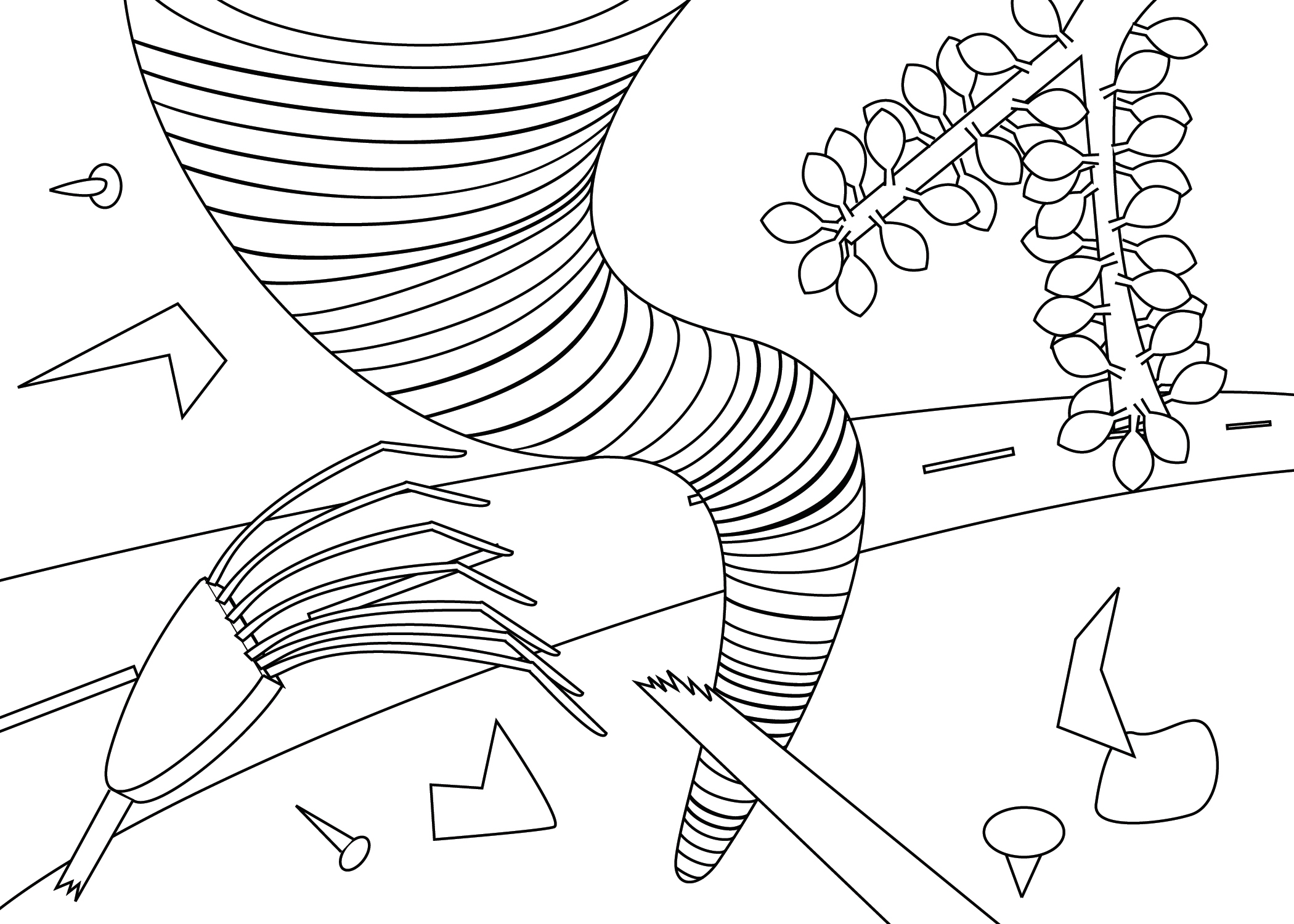

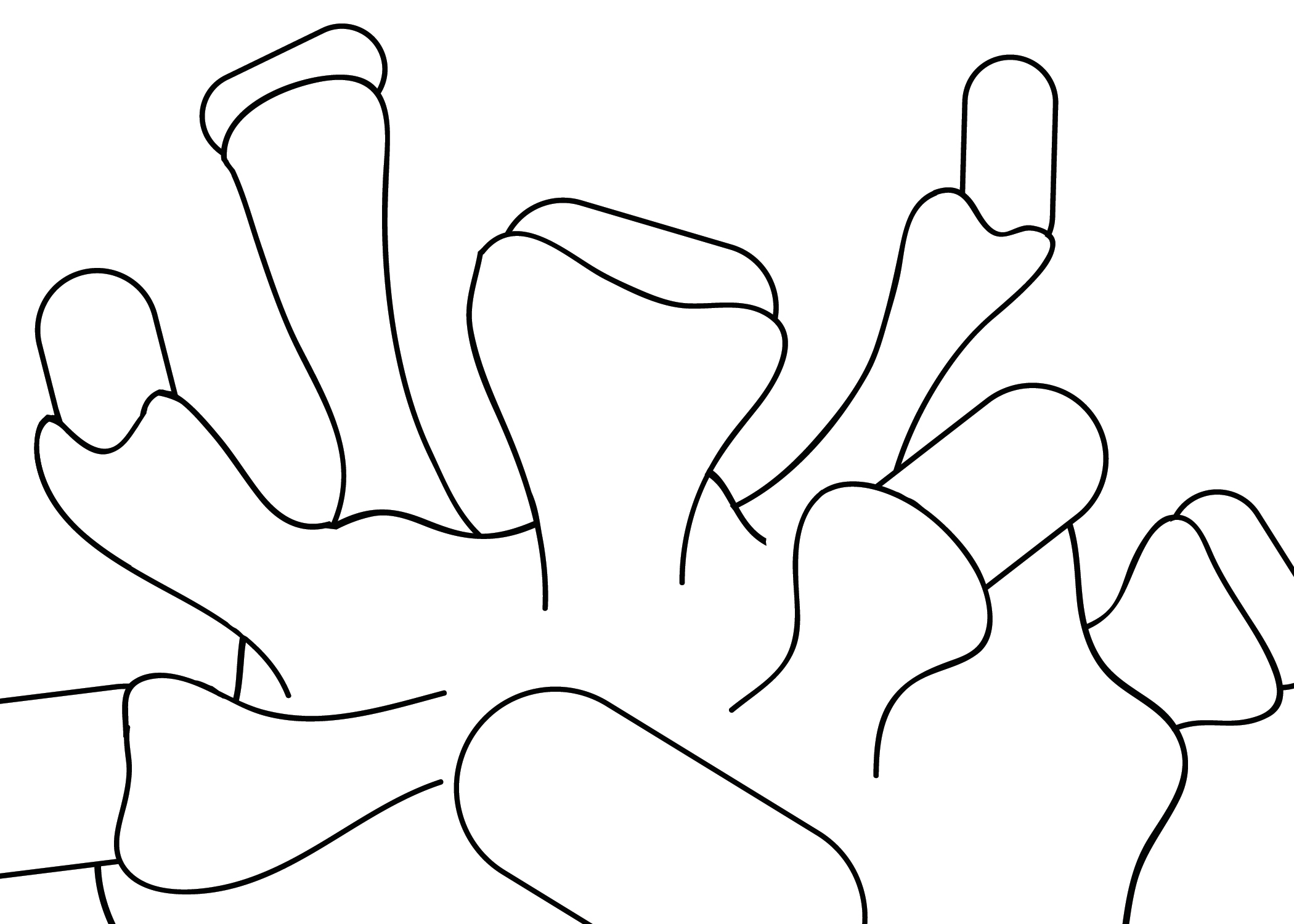

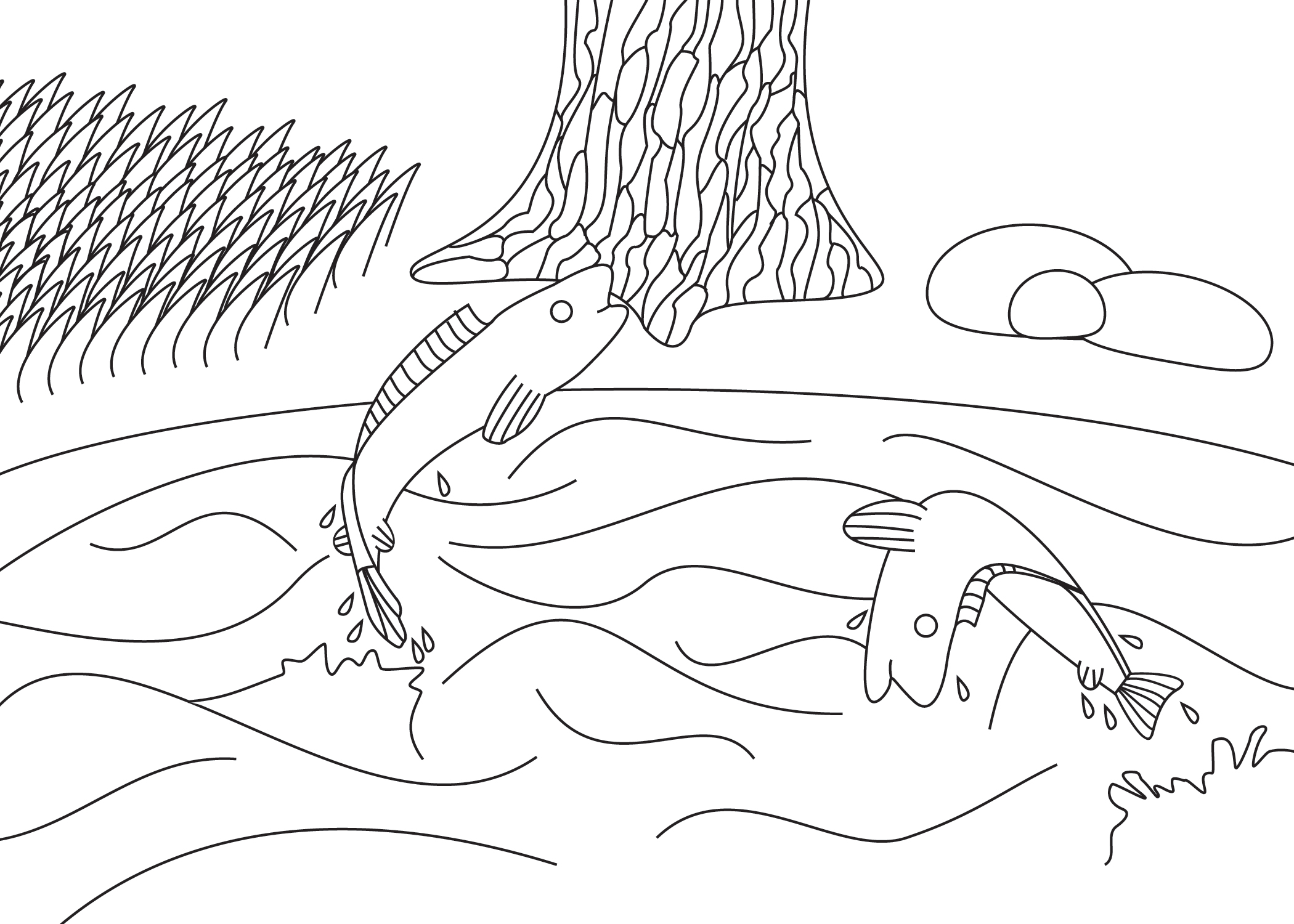

STEM Coloring Book

A biology teacher at Metropolitan State University of Denver asked me to create a coloring book for the upcoming summer Science STEM program hosted at the university. Coloring sheet topics range from chemistry to meteorology.

Genetics

Chemistry

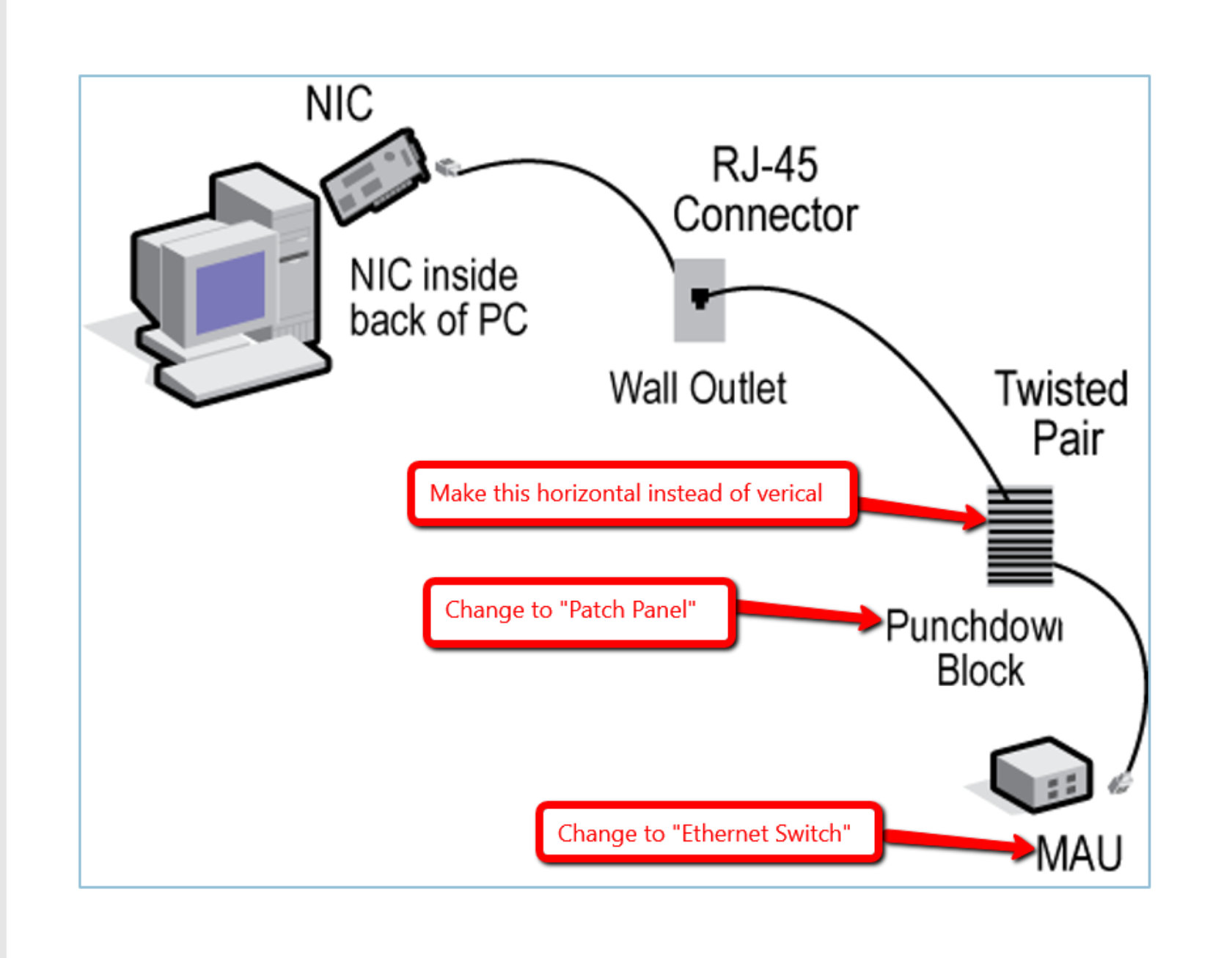

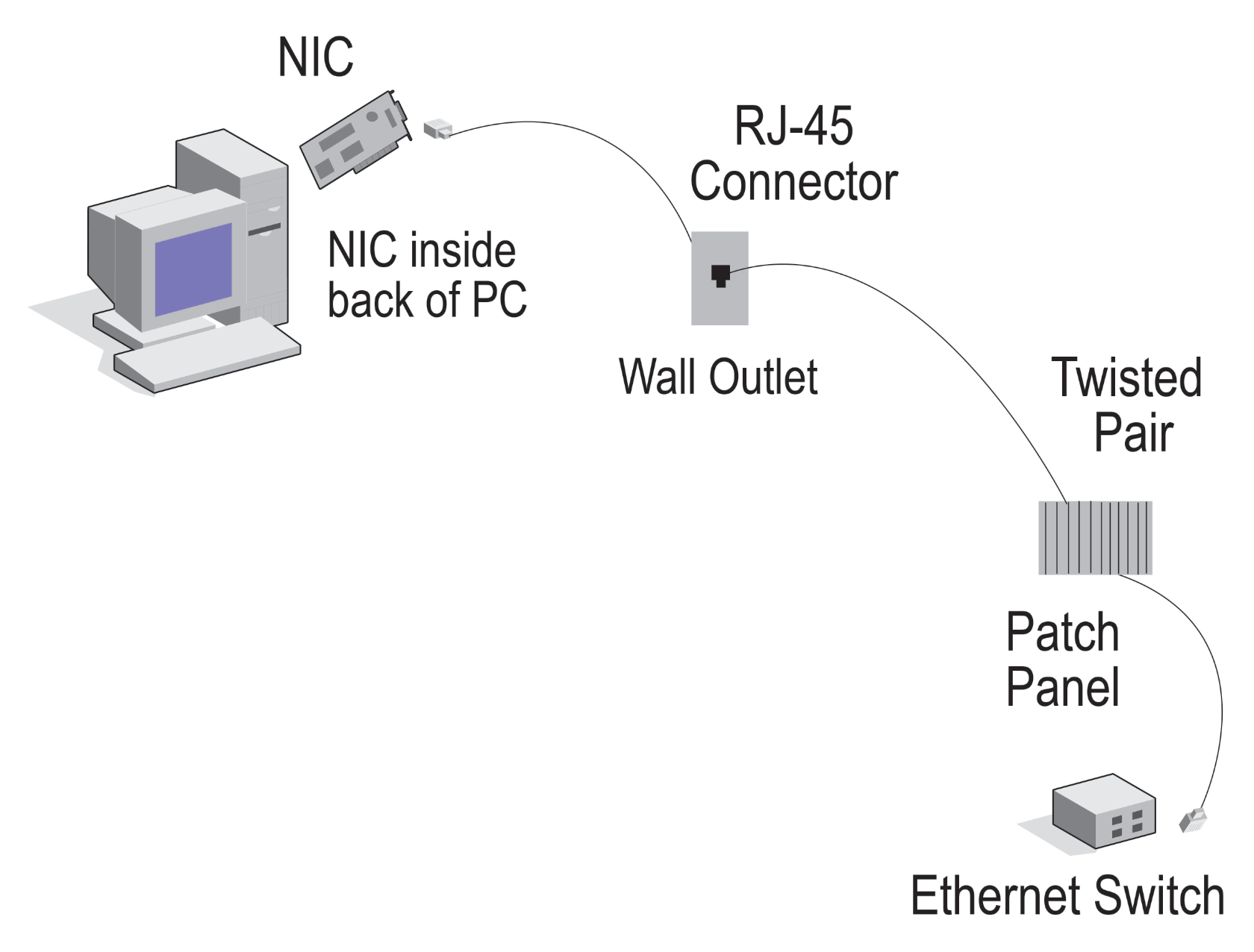

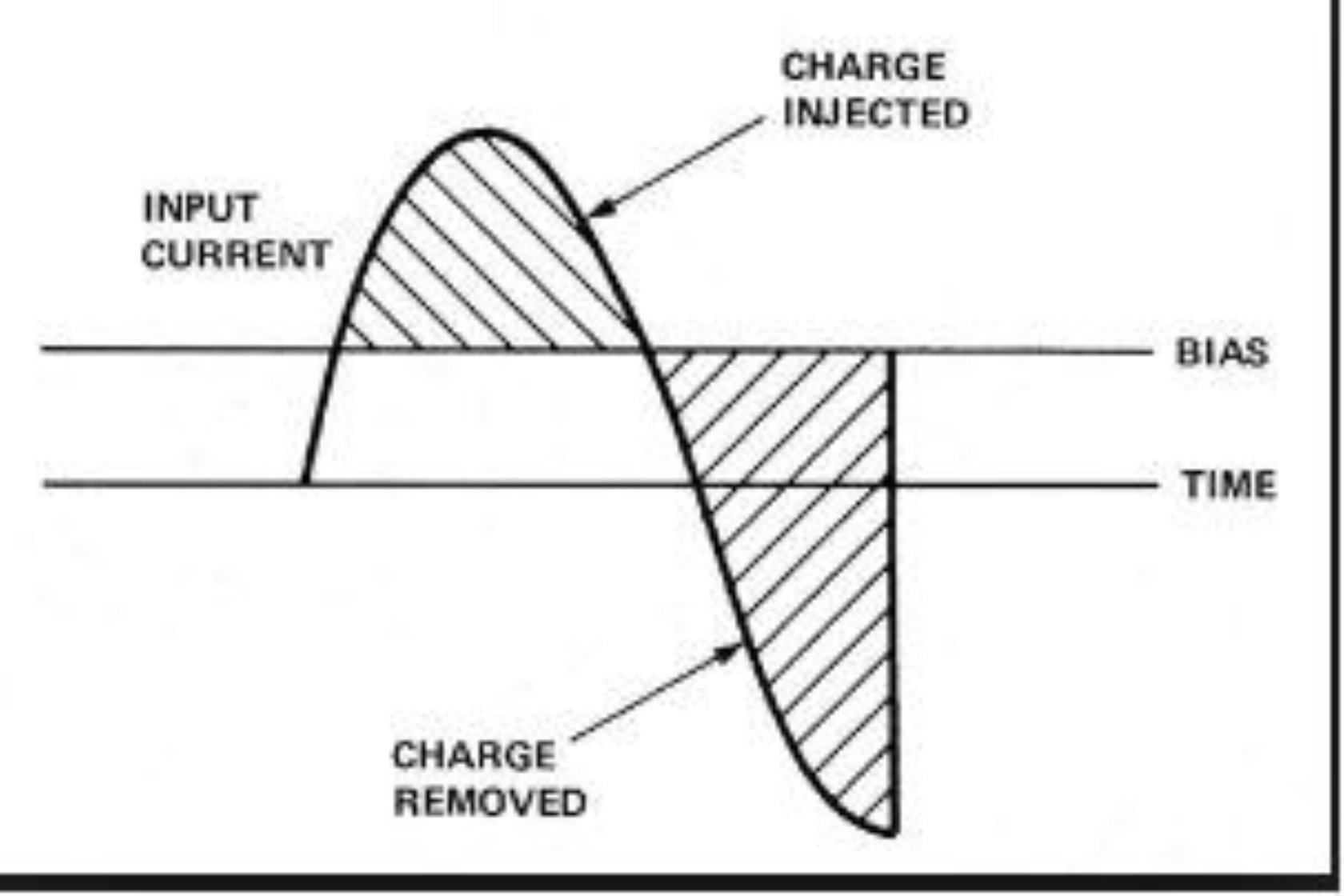

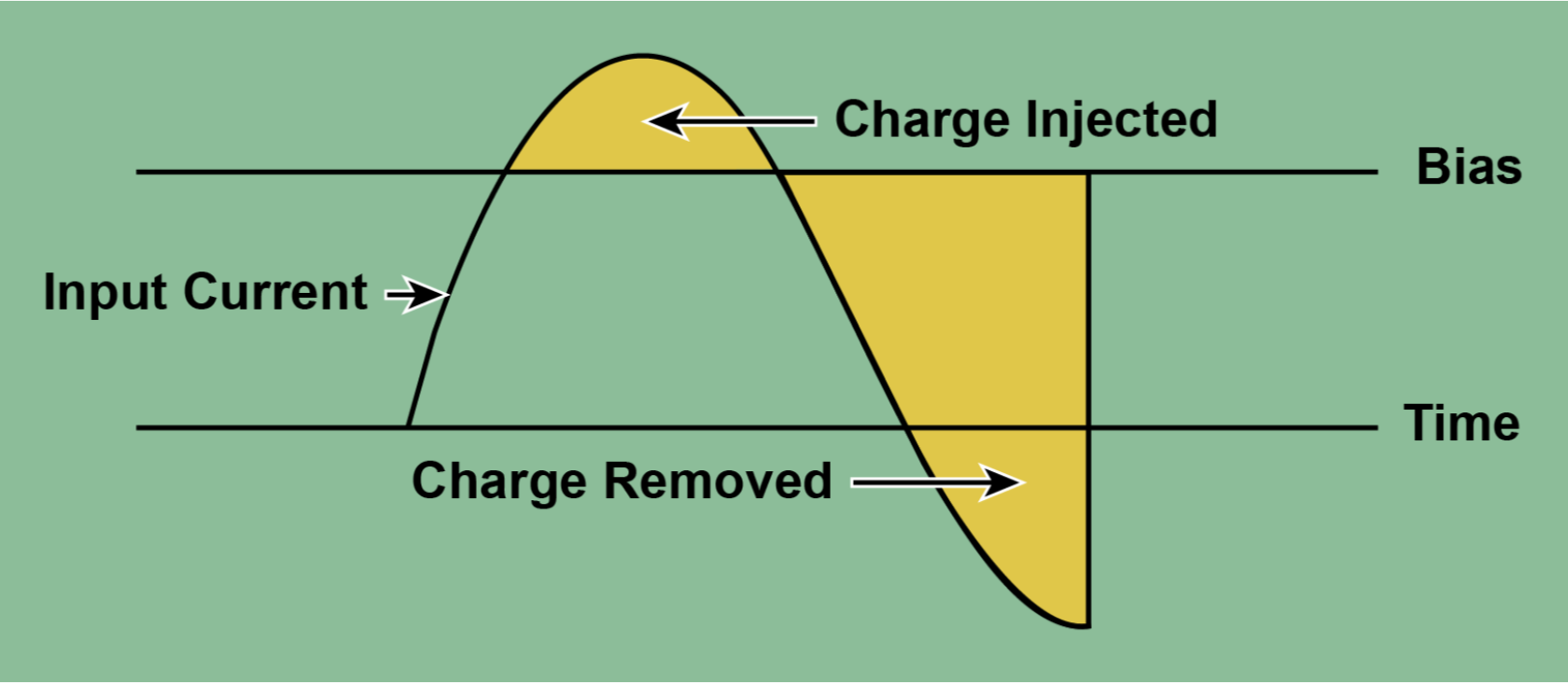

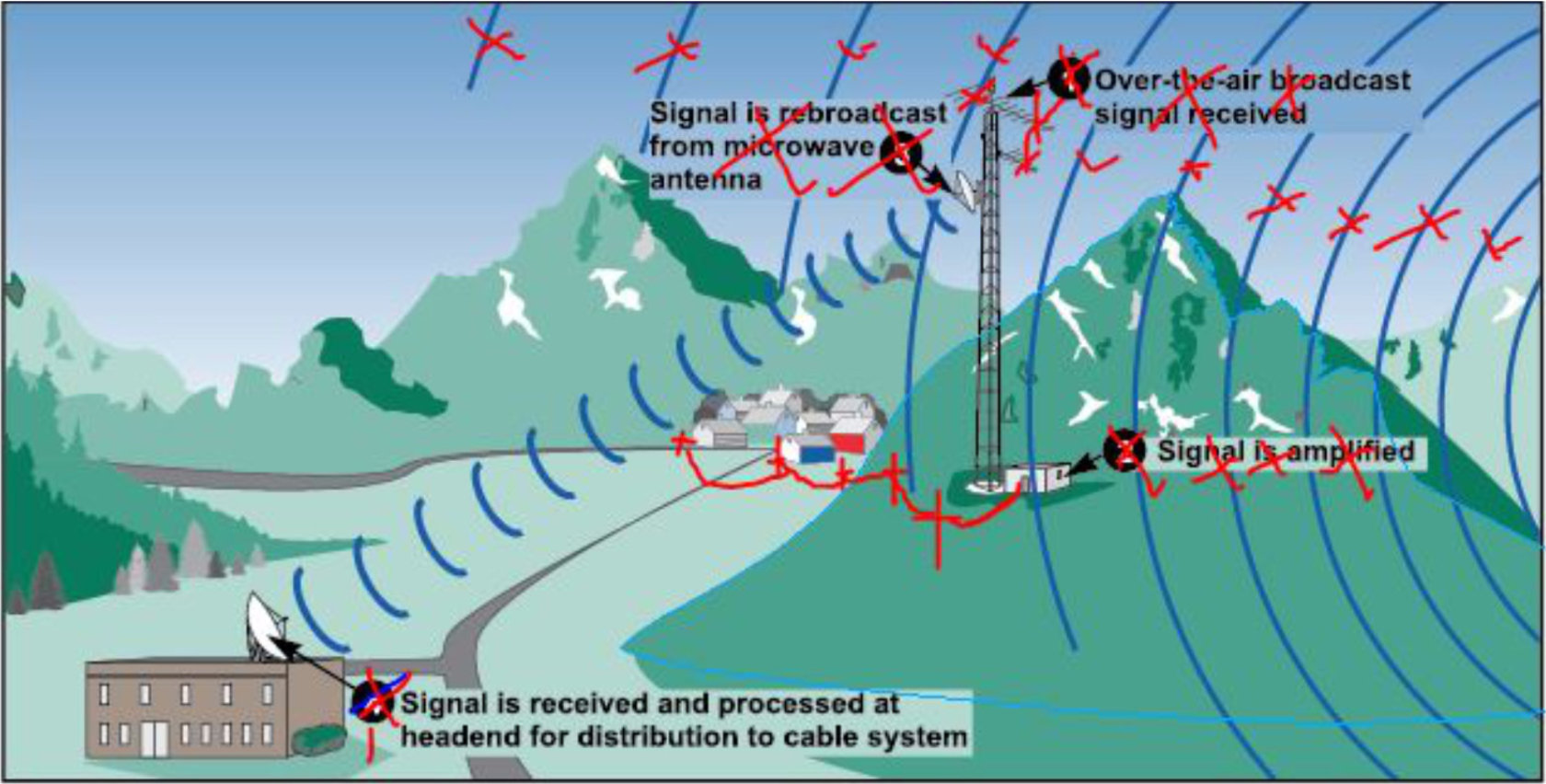

Computer Science

3D Printing

Math

Meteorology

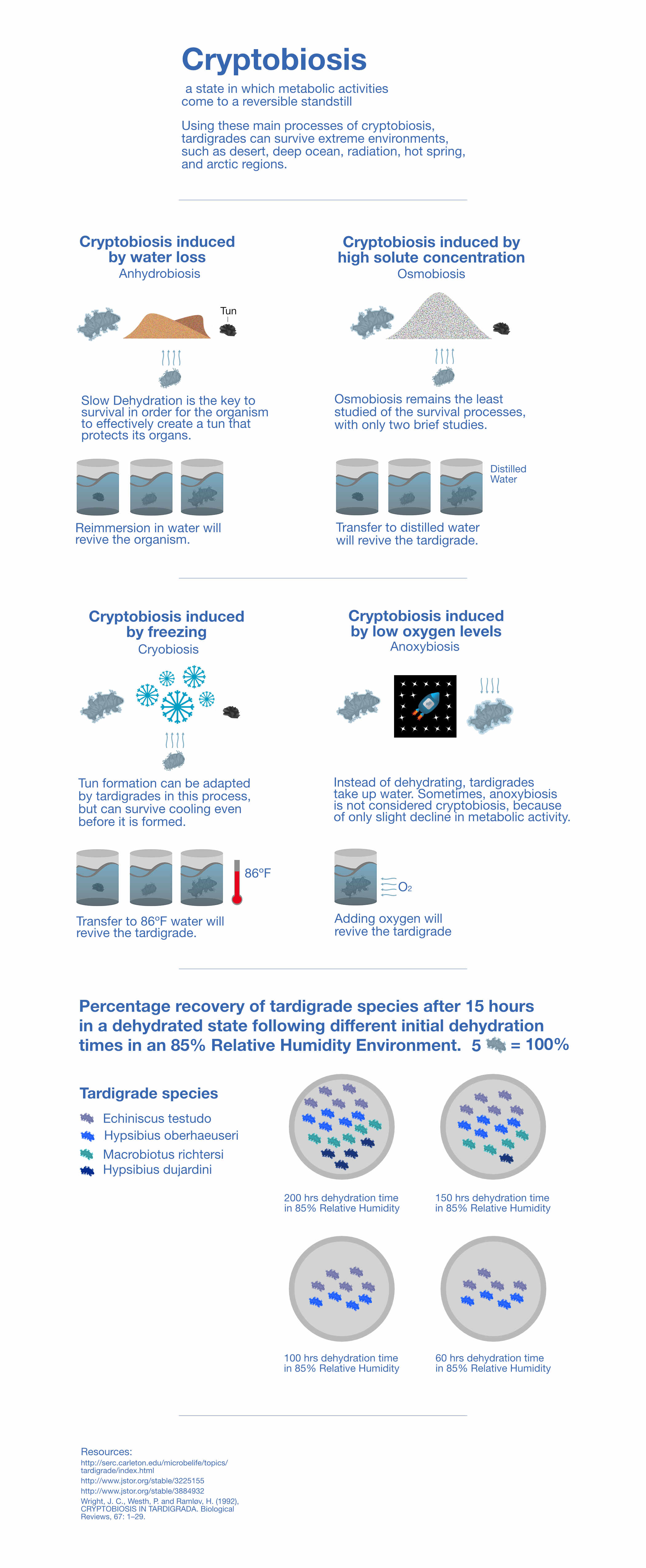

Microbiology

Water Environments

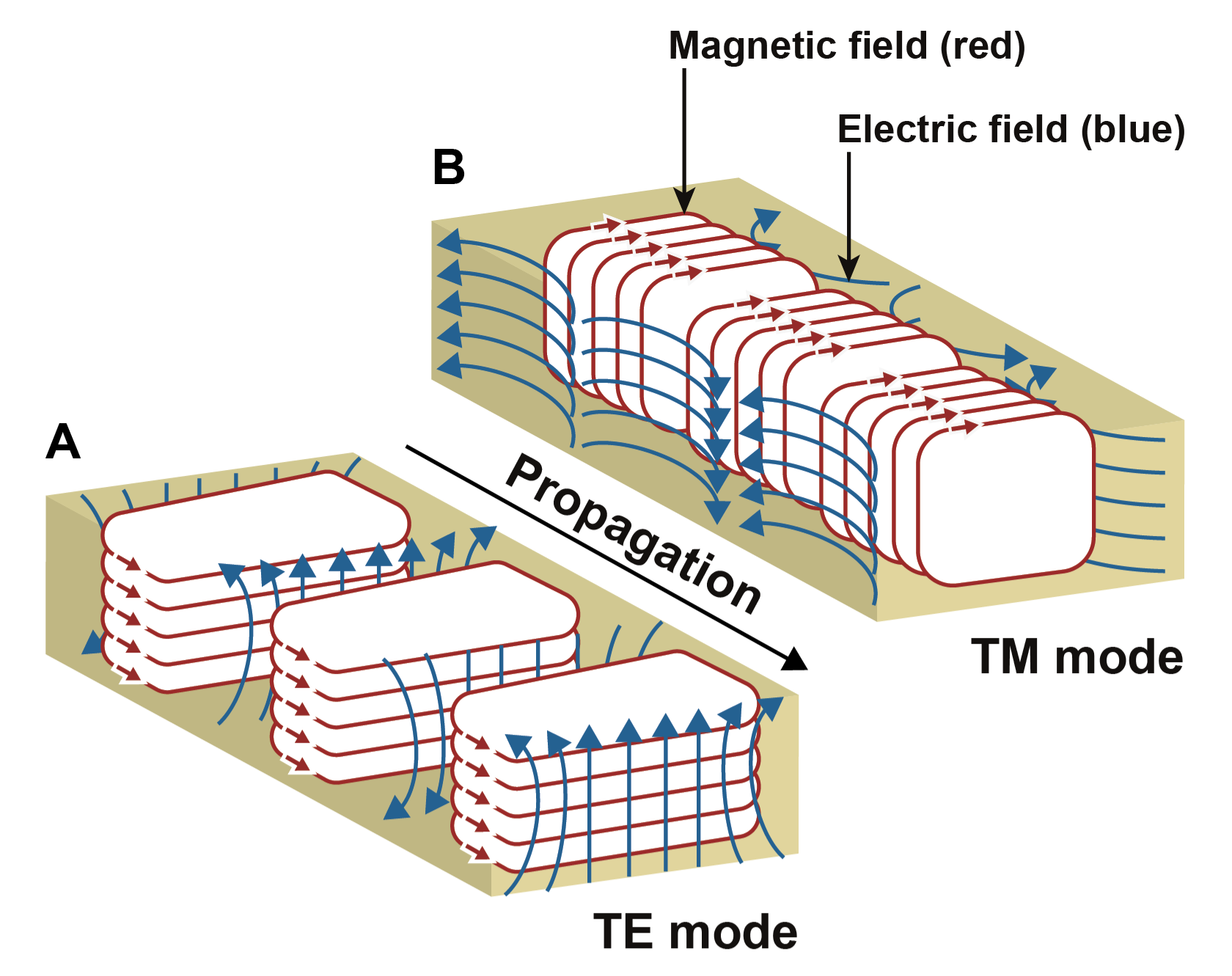

Physics

Rocket Science

Design Building

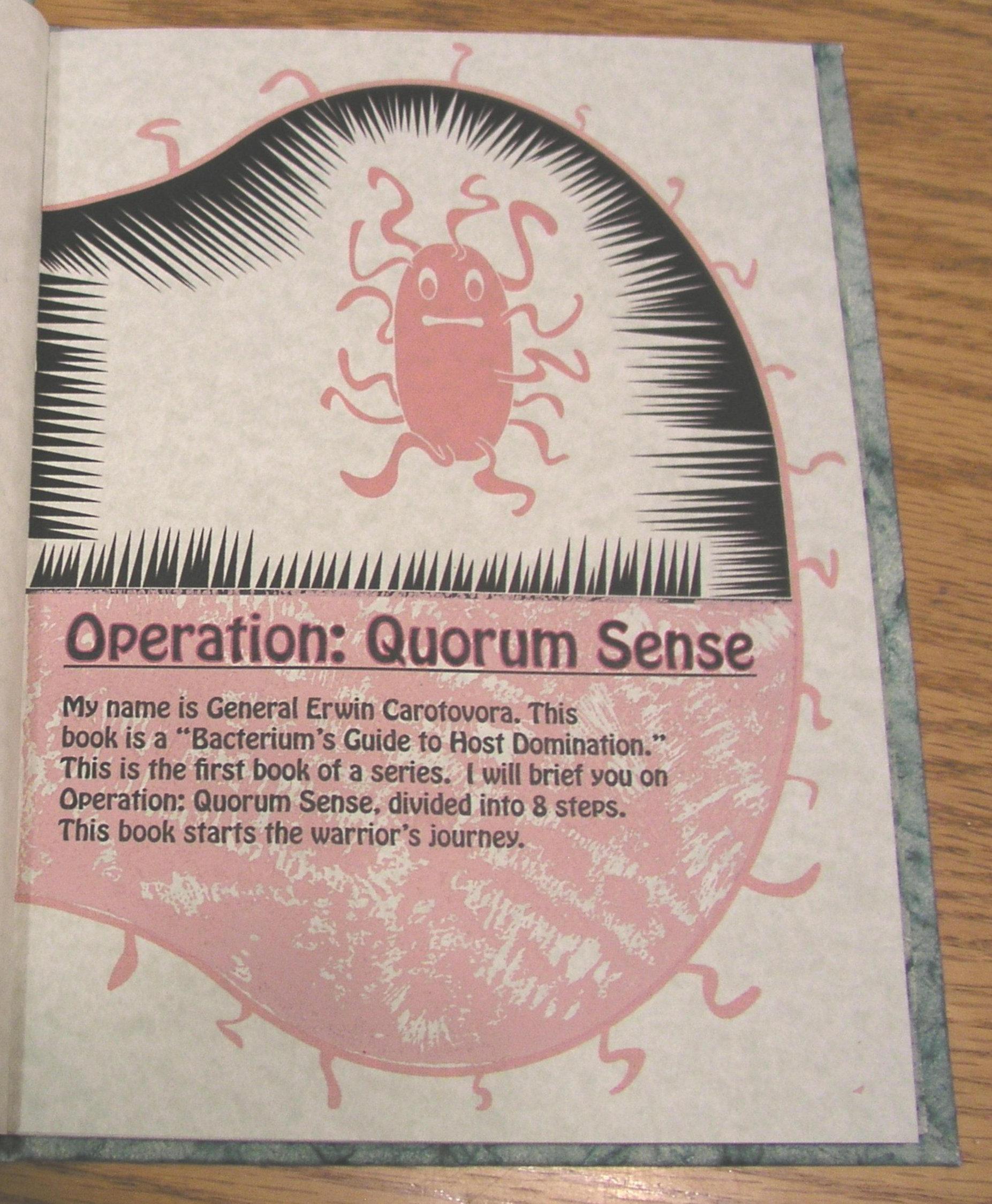

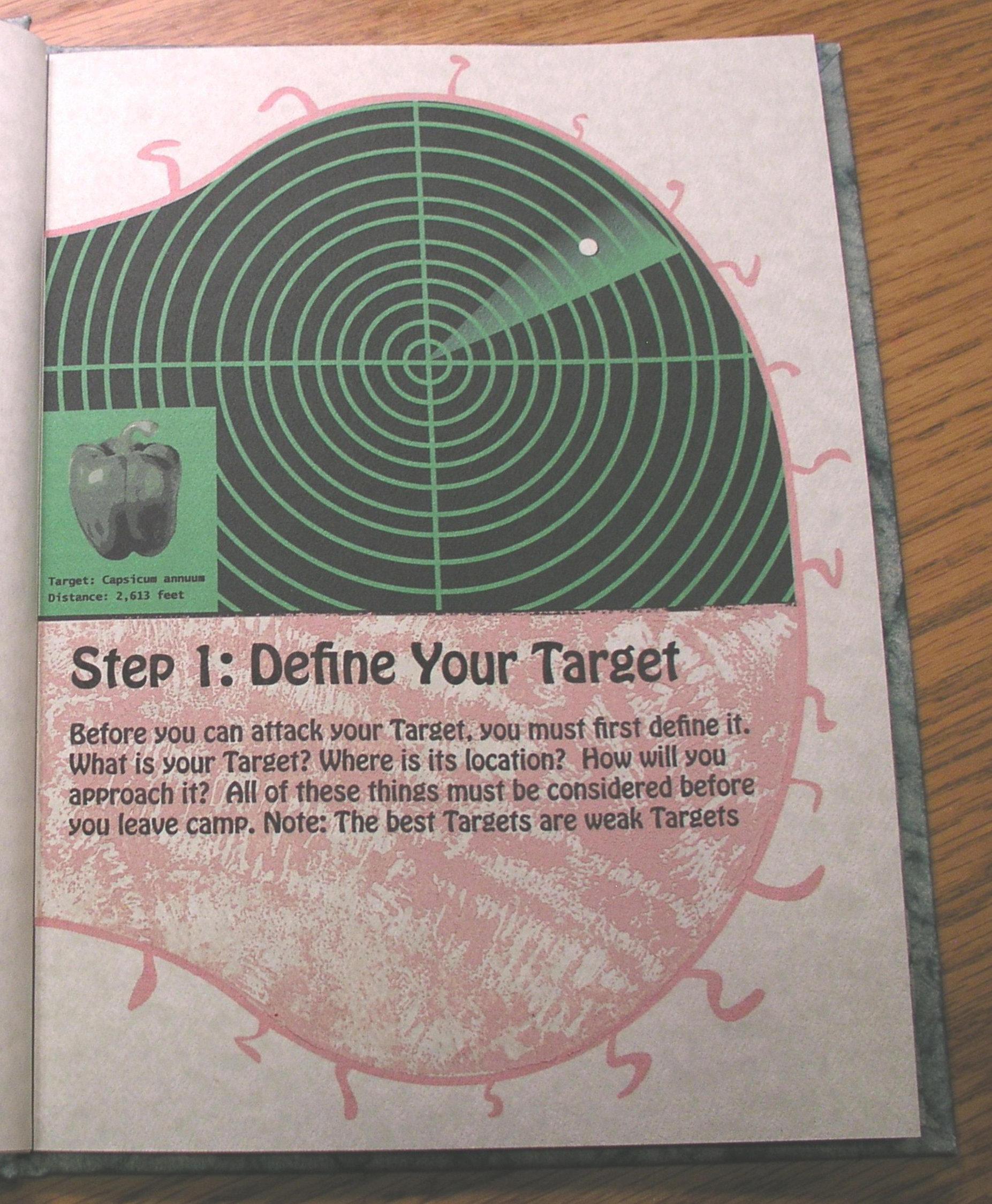

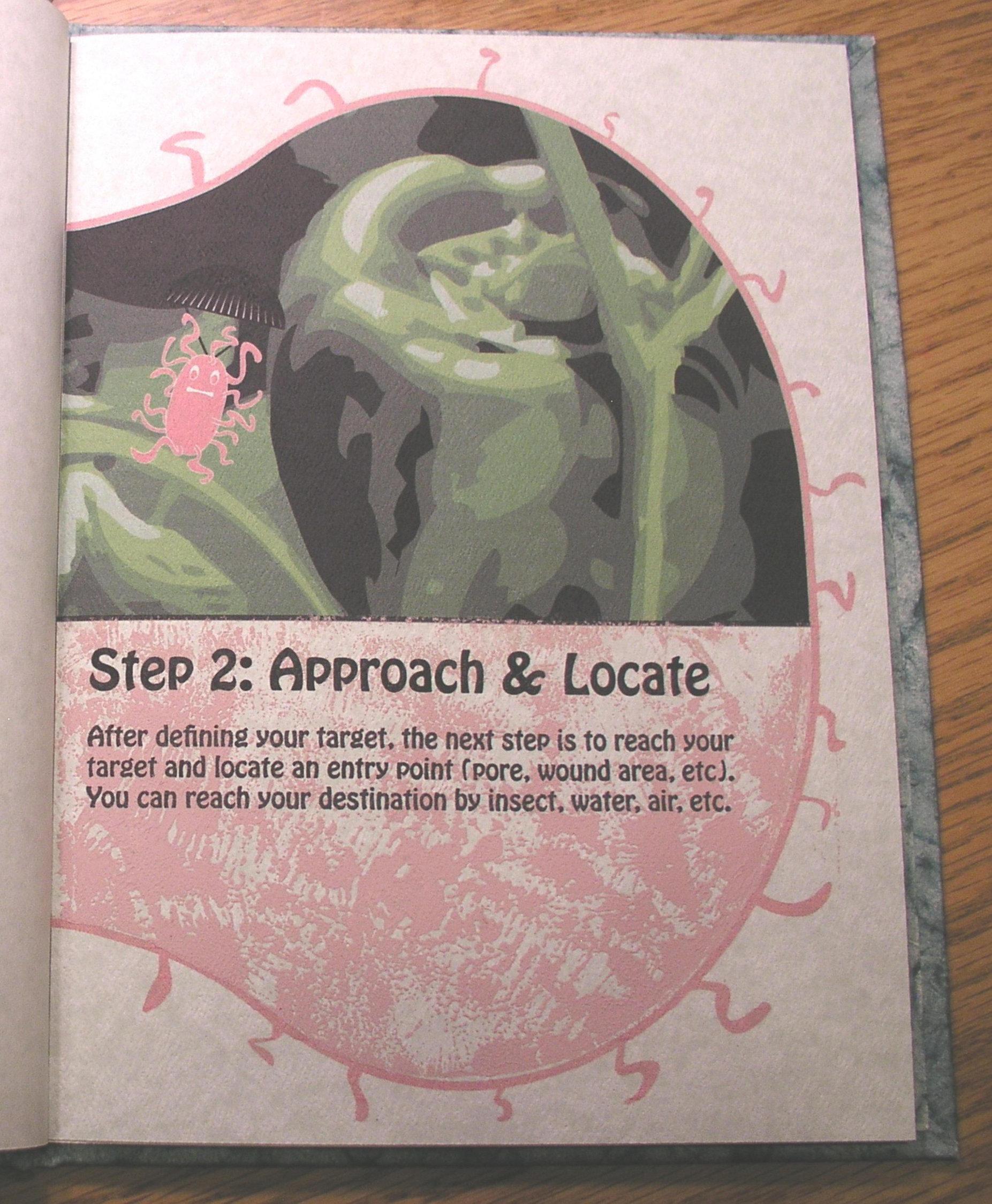

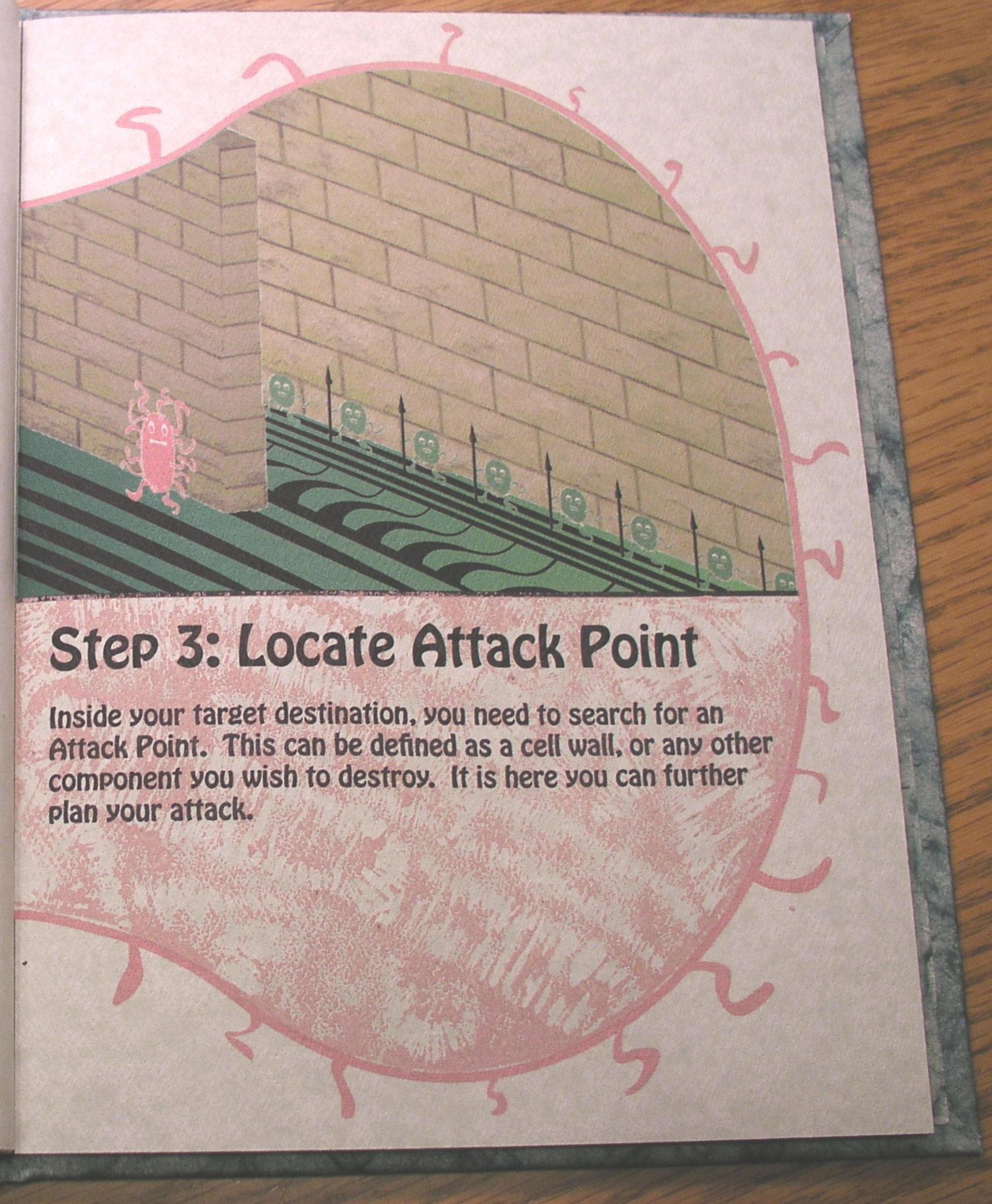

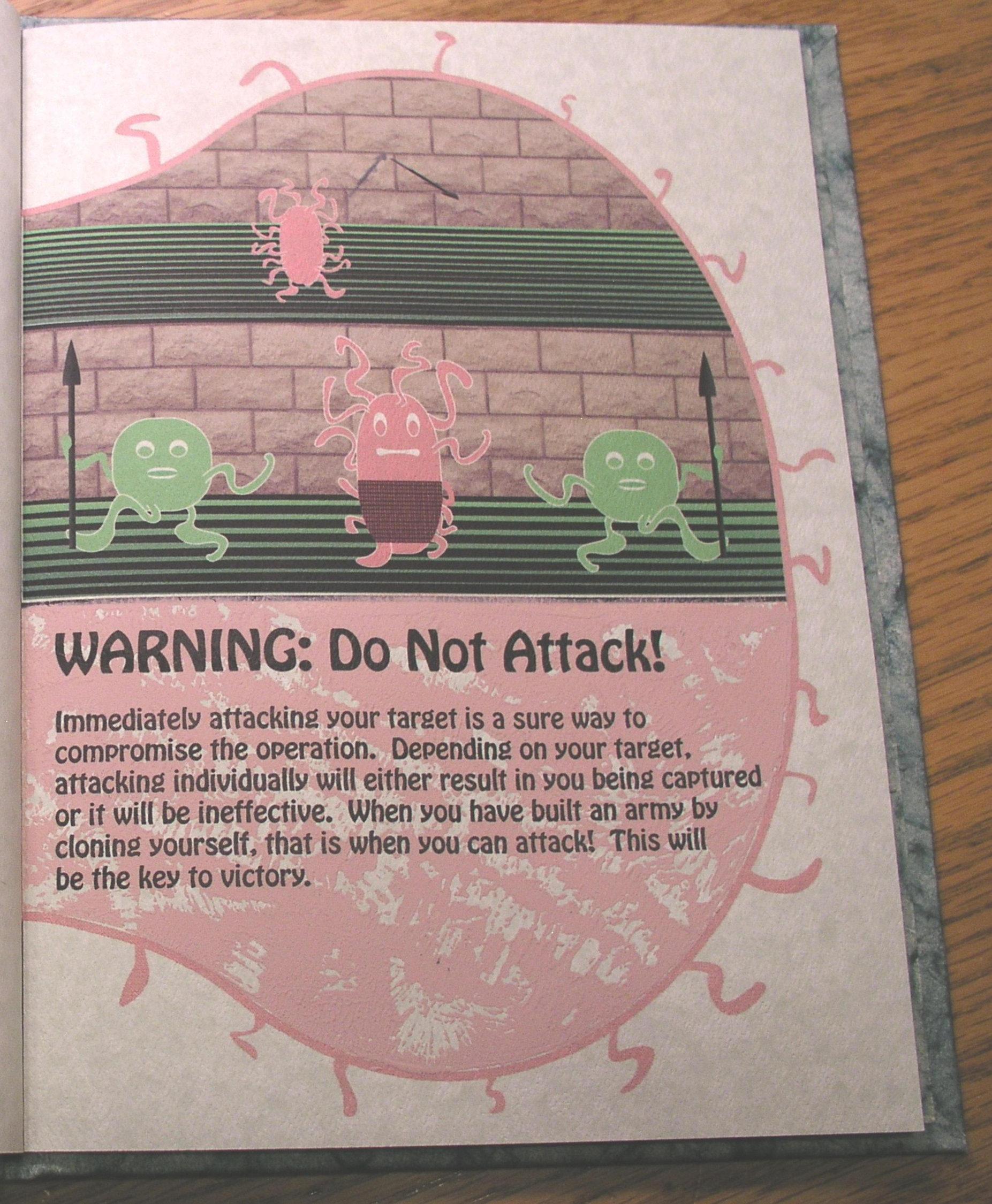

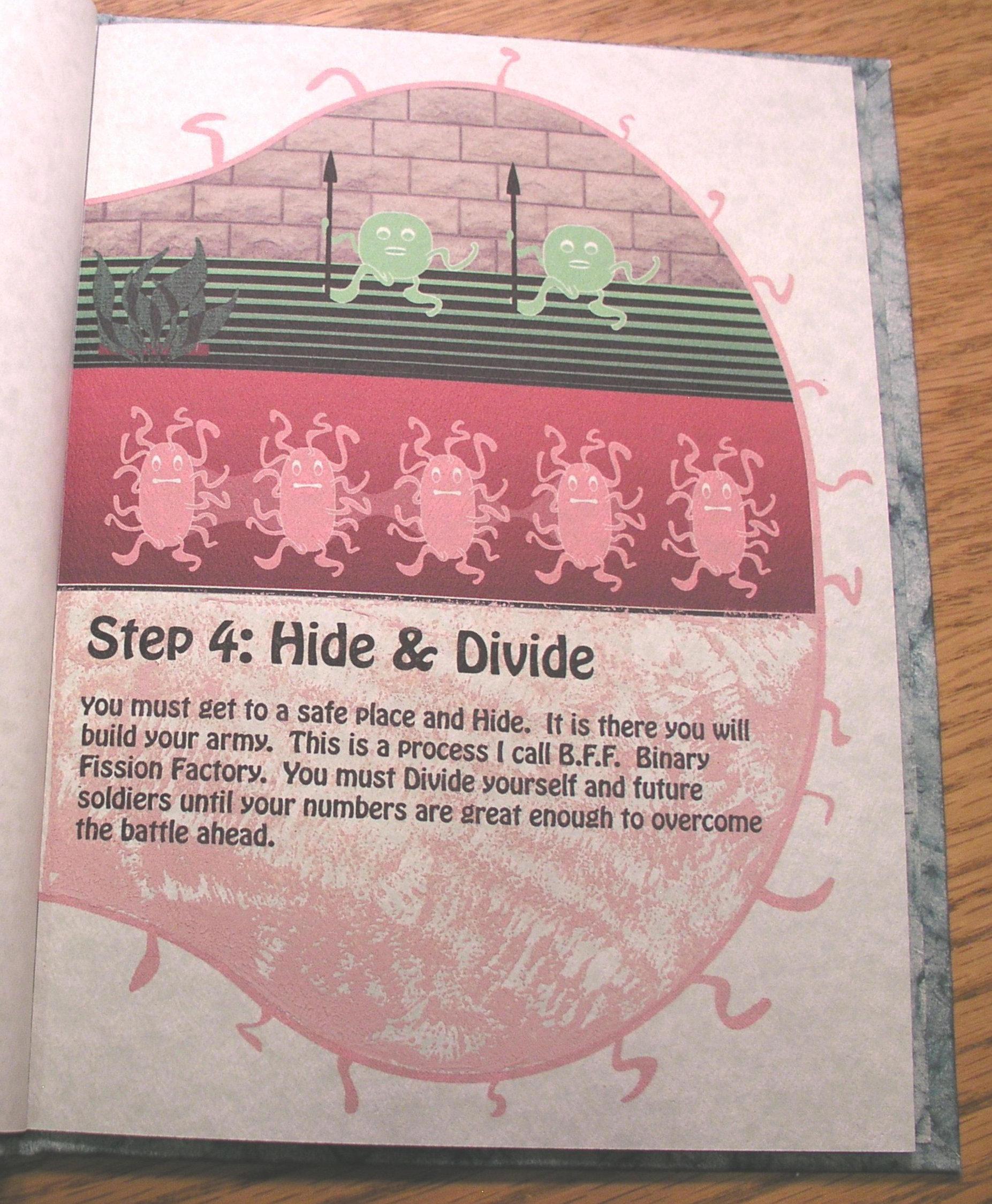

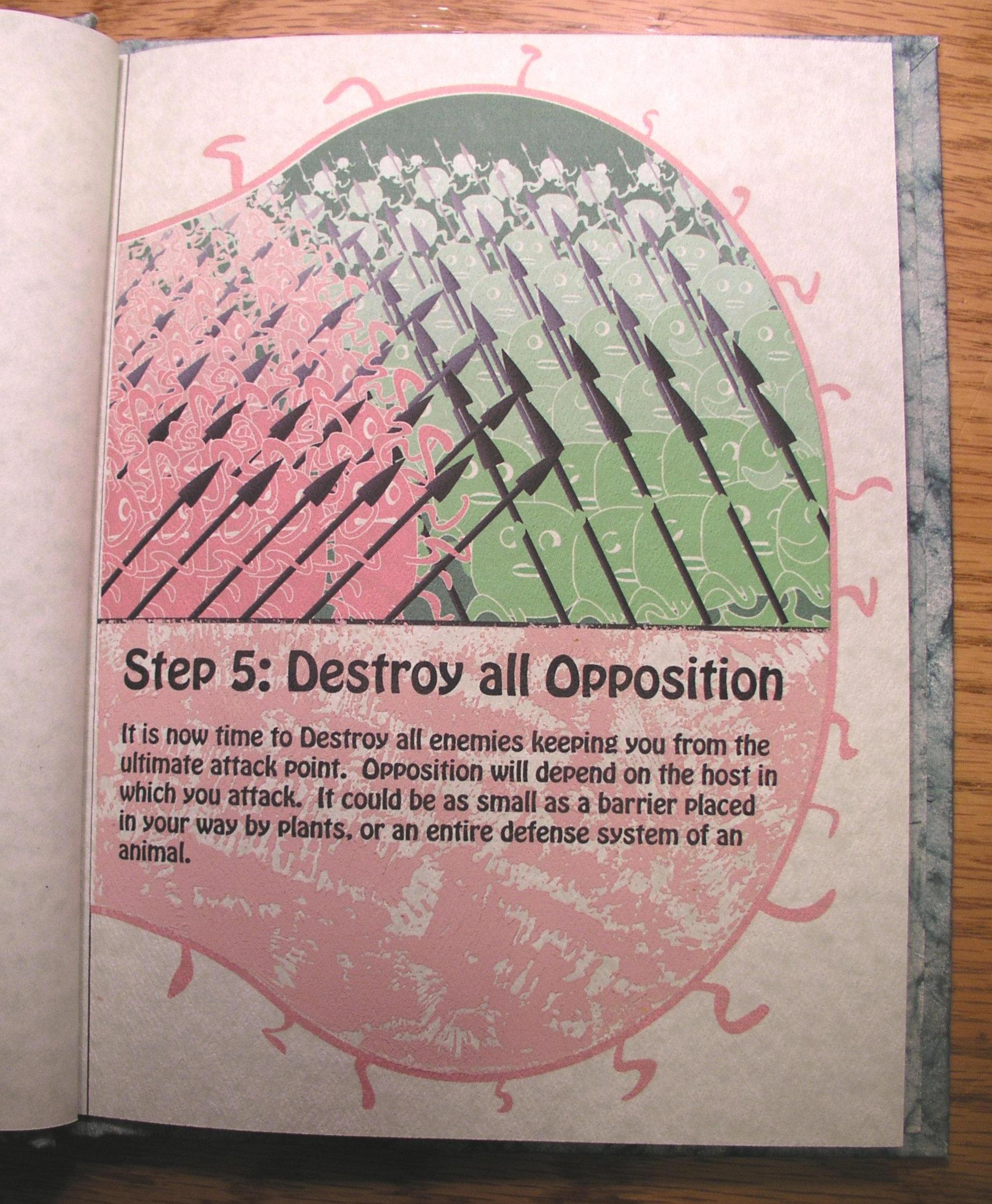

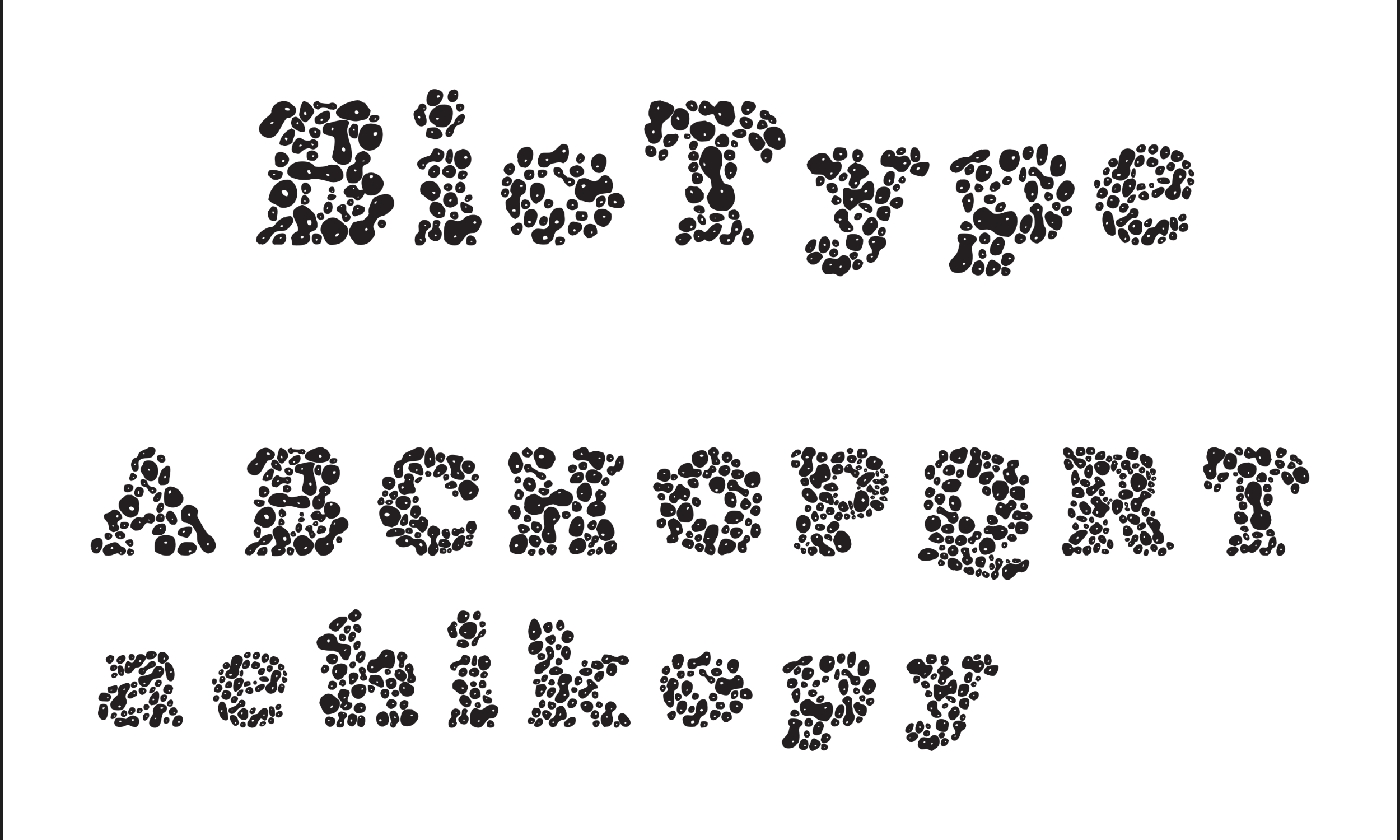

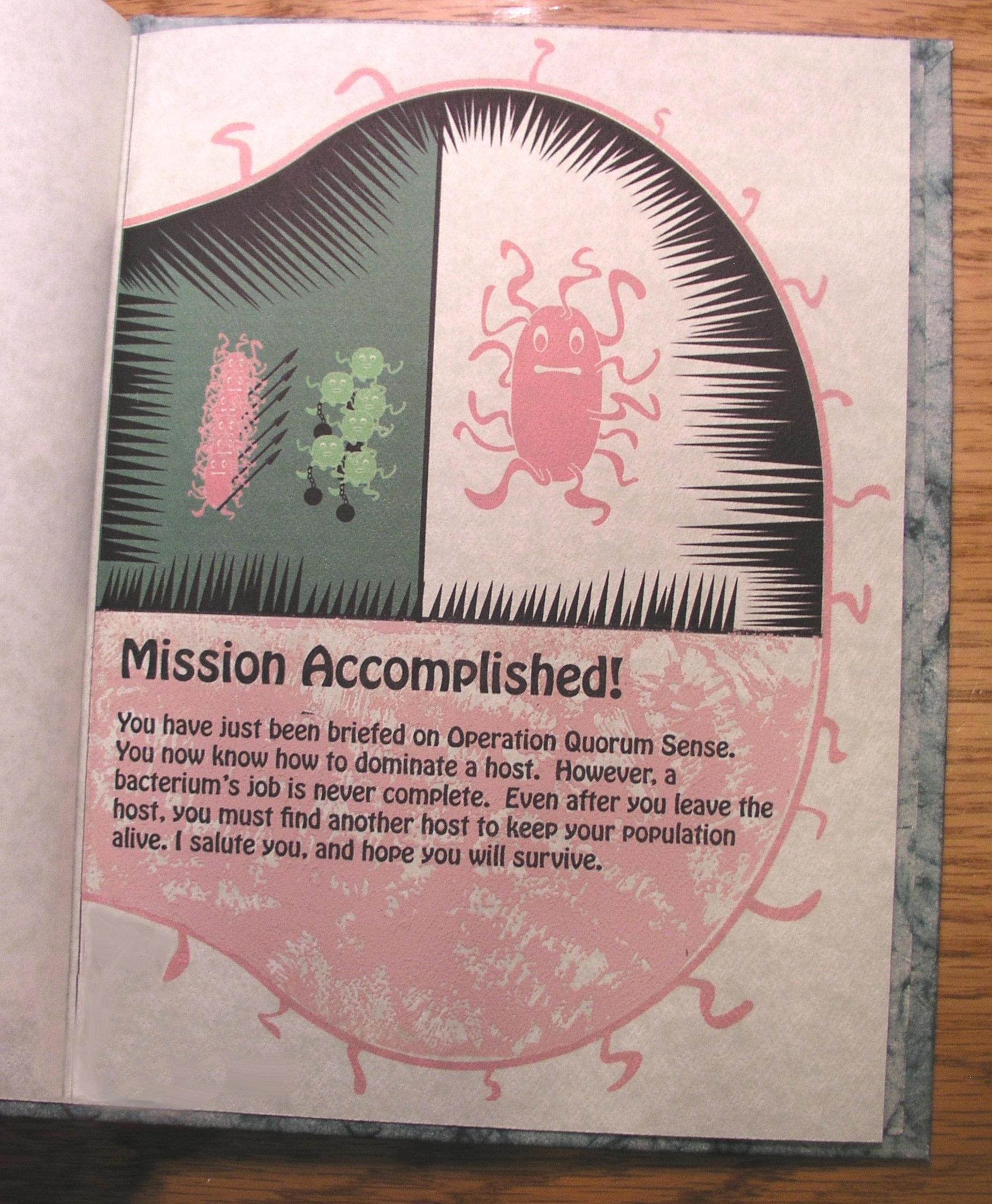

Operation: Quorum Sense

In my 2D Design class, the teacher asked the students to incorporate post-contemporary design principles. I was in a microbiology class at the same time. I was interested in making a complicated biology topic, quorum sensing, simpler.